Abstract

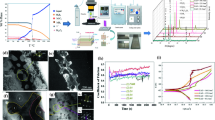

Fretting damage under high temperature corrosion and wear condition is one of the main factors that cause the failure of the key parts of mechanical and electrical equipment, and laser cladding wear-resistant and corrosion-resistant coating is the main technology to repair these failure key parts. In this paper, the layered 50Cr6Ni2/Stellite X-40 multi-material was prepared by direct laser deposition (DLD) using wear-resistant Fe-based alloy and corrosion-resistant Co-based alloy, to meet the needs of repair and remanufacturing of key parts with fretting damage. The results show that the layered 50Cr6Ni2/Stellite X-40 composite material retains their respective microstructures and excellent properties. The microstructure of the 50Cr6Ni2 layer mainly contains martensite and granular bainite, the microstructure of the Stellite X-40 layer consists of dendrite and eutectic structure. The layered 50Cr6Ni2/Stellite X-40 composite material has both good wear resistance (wear mass loss is 1.0 mg) and good corrosion resistance (− 0.37549 of Ecorr and 0.00032 of icorr). The DLD layered 50Cr6Ni2/Stellite X-40 composite material could meet the demand of short stress path rolling mill remanufacturing.

Graphic Abstract

In order to meet the needs of repair and remanufacturing of key parts with fretting damage, the layered 50Cr6Ni2/Stellite X-40 multi-material was prepared by direct laser deposition (DLD) using wear-resistant Fe-based alloy and corrosion-resistant Co-based alloy. As shown in Fig. 1a, the samples were fabricated by using the DLD system. Figure 1b, c shows the EBSD analysis of the layered 50Cr6Ni2/Stellite X-40 multi-material at the interface, which clearly displays the existence of the interface. In some regions, blocky retained austenite can be found (Fig. 1d), and it can be clearly observed that the substructure within granular bainite are sheaves with lath-shaped in Fig. 1e. In the 50Cr6Ni2 layer of layered multi-material, the microstructure mainly contained martensite (Fig. 1f, g). Figure 1h, i show that the layered 50Cr6Ni2/Stellite X-40 composite material has both good wear resistance and good corrosion resistance. The results show that the layered 50Cr6Ni2/Stellite X-40 composite material retains their respective microstructures and excellent properties, and it could meet the demand of short stress path rolling mill remanufacturing. Layered 50Cr6Ni2/Stellite X-40 multi-material fabricated by direct laser deposition: characterization and properties (Fig. 1).

Similar content being viewed by others

References

Y.J. Li, S.Y. Dong, S.X. Yan, X.T. Liu, P. He, B.S. Xu, Surf. Coat. Technol. 20, 347 (2018)

A. Riquelme, P. Rodrigo, M.D. Escalera-Rodríguez, J. Rams, Opt. Lasers Eng. 165, 78 (2016)

Z. Zhao, J. Chen, H. Tan, X.L. Zhao, W.D. Huang, Rare Metal Mater. Eng. 1792, 46 (2017)

Y. Zhu, Y. Yang, X. Mu, W. Wang, Z. Yao, H. Yang, Wear 126, 430 (2019)

H.M. Chen, F.C. Liu, G. Yang, C. Zhong, X. Lin, C.P. Huang, Rare Metal Mater. Eng. 2949, 47 (2018)

J.M. Wilson, C. Piya, Y.C. Shin, F. Zhao, K. Ramani, J. Clean. Prod. 170, 80 (2014)

S.T. Peng, T. Li, M.Y. Li, Y.C. Guo, J.L. Shi, G.Z. Tan, H.C. Zhang, J. Clean. Prod. 598, 206 (2019)

H.D. Zheng, E.Z. Li, Y. Wang, P.J. Shi, B.S. Xu, S.L. Yang, Robot. Comput. Integr. Manuf. 213, 59 (2019)

Z.B. Xu, J.F. Peng, J.H. Liu, X.Y. Liu, W.L. Zhang, M.H. Zhu, Wear 704, 426 (2019)

J.F. Peng, B.T. Wang, X. Jin, Z.B. Xu, J.H. Liu, Z.B. Cai, Z.P. Luo, M.H. Zhu, Tribol. Int. 1, 137 (2019)

W.J. Chen, H. Chen, C.C. Li, X.L. Wang, Q. Cai, Eng. Fail. Anal. 120, 79 (2017)

J.H. Jang, B.D. Joo, S.M. Mun, M.Y. Sung, Y.H. Moon, Met. Mater. Int. 17, 167 (2011)

J.M.S.D. Sousa, F. Ratusznei, M. Pereira, R.D.M. Castro, E.I.M. Curi, Tribol. Int. 106002, 143 (2020)

G.Y. Baek, G.Y. Shin, E.M. Lee, D.S. Shim, K.Y. Lee, H.S. Yoon, M.H. Kim, Met. Mater. Int. 23, 770 (2017)

J. Zhao, Q.W. Gao, H.Q. Wang, F.Y. Shu, H.Y. Zhao, W.X. He, Z.S. Yu, J. Alloys Compd. 846, 785 (2019)

X. Li, C.H. Zhang, S. Zhang, C.L. Wu, Y. Liu, J.B. Zhang, M.B. Shahzad, Opt. Laser Technol. 209, 114 (2019)

B.C. Li, H.M. Zhu, C.J. Qiu, X.K. Gong, Mater. Lett. 126829, 259 (2020)

M.N. Fesharaki, R. Shoja-Razavi, H.A. Mansouri, H. Jamali, Opt. Laser Technol. 744, 111 (2019)

E. Diaz, J.M. Amado, J. Montero, M.J. Tobar, A. Yanez, Phys. Proc. 368, 39 (2012)

M. Nabhani, R.S. Razavi, M. Barekat, Eng. Fail. Anal. 234, 97 (2019)

B. Heer, A. Bandyopadhyay, Mater. Lett. 16, 216 (2018)

B. Onuike, A. Bandyopadhyay, Addit. Manuf. 576, 27 (2019)

H. Sahasrabudhe, R. Harrison, C. Carpenter, A. Bandyopadhyay, Addit. Manuf. 1, 5 (2015)

C. Shang, C.Y. Wang, G.J. Xu, C.F. Li, J.H. You, Vacuum 108888, 169 (2019)

P.F. Zuo, S.Y. Chen, M.Y. Wei, L. Zhou, J. Liang, C.S. Liu, M. Wang, J. Mater. Process Technol. 28, 444 (2019)

Y. Zhou, S.Y. Chen, X.T. Chen, T. Cui, J. Liang, C.S. Liu, Mater. Sci. Eng. A 150, 742 (2019)

T.T. Guan, S.Y. Chen, X.T. Chen, J. Liang, C.S. Liu, M. Wang, J Mater. Sci. Technol. 395, 35 (2019)

M.Y. Wei, S.Y. Chen, L.Y. Xi, J. Liang, C.S. Liu, Opt. Laser Technol. 99, 107 (2018)

L. Parry, I.A. Ashcroft, R.D. Wildman, Addit. Manuf. 1, 12 (2016)

J.Y. Shao, G. Yu, X.L. He, S.X. Li, R. Chen, Y. Zhao, Opt. Laser Technol. 105662, 119 (2019)

N. Takayama, G. Miyamoto, T. Furuhara, Acta Mater. 154, 145 (2018)

S.S. Liu, Y.H. Wang, W.P. Zhang, Rare Metal Mater. Eng. 1041, 43 (2014)

S.L. Sing, L.P. Lam, D.Q. Zhang, Z.H. Liu, C.K. Chua, Mater. Charact. 107, 220–227 (2015)

K. Peng, C.L. Yang, C.L. Fan, S.B. Lin, J. Mater. Process Technol. 225, 251 (2018)

Acknowledgements

This work was financially supported by the National Key R&D Program of China (No. 2016YFB1100201), the Green Manufacturing System Integration Project of the Industry and Information Ministry of China (2017), the Research and development plan for the future emerging industries in Shenyang (18-004-2-26).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, H., Chen, S., Zhang, C. et al. Layered 50Cr6Ni2/Stellite X-40 Multi-material Fabricated by Direct Laser Deposition: Characterization and Properties. Met. Mater. Int. 27, 40–49 (2021). https://doi.org/10.1007/s12540-020-00675-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00675-z