Abstract

The theory of grain boundary (the interface between crystallites, GB) structure has a long history1 and the concept of GBs undergoing phase transformations was proposed 50 years ago2,3. The underlying assumption was that multiple stable and metastable states exist for different GB orientations4,5,6. The terminology ‘complexion’ was recently proposed to distinguish between interfacial states that differ in any equilibrium thermodynamic property7. Different types of complexion and transitions between complexions have been characterized, mostly in binary or multicomponent systems8,9,10,11,12,13,14,15,16,17,18,19. Simulations have provided insight into the phase behaviour of interfaces and shown that GB transitions can occur in many material systems20,21,22,23,24. However, the direct experimental observation and transformation kinetics of GBs in an elemental metal have remained elusive. Here we demonstrate atomic-scale GB phase coexistence and transformations at symmetric and asymmetric \([11\bar{1}]\) tilt GBs in elemental copper. Atomic-resolution imaging reveals the coexistence of two different structures at Σ19b GBs (where Σ19 is the density of coincident sites and b is a GB variant), in agreement with evolutionary GB structure search and clustering analysis21,25,26. We also use finite-temperature molecular dynamics simulations to explore the coexistence and transformation kinetics of these GB phases. Our results demonstrate how GB phases can be kinetically trapped, enabling atomic-scale room-temperature observations. Our work paves the way for atomic-scale in situ studies of metallic GB phase transformations, which were previously detected only indirectly9,15,27,28,29, through their influence on abnormal grain growth, non-Arrhenius-type diffusion or liquid metal embrittlement.

This is a preview of subscription content, access via your institution

Access options

Access Nature and 54 other Nature Portfolio journals

Get Nature+, our best-value online-access subscription

$29.99 / 30 days

cancel any time

Subscribe to this journal

Receive 51 print issues and online access

$199.00 per year

only $3.90 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

Data availability

Datasets generated or analysed during the current study are available in Edmond (the Open Access Data Repository of the Max Planck Society) under https://edmond.mpdl.mpg.de/imeji/collection/zV4i2cu2bIAI8B. All other datasets are available from the corresponding authors on reasonable request.

References

Sutton, A. P. & Balluffi, R. W. Interfaces in Crystalline Materials (Clarendon Press, 1995).

Hart, E. W. Two-dimensional phase transformation in grain boundaries. Scr. Metall. 2, 179–182 (1968).

Hart, E. W. The Nature and Behavior of Grain Boundaries 155–170 (Springer, 1972).

Cahn, J. W. Transitions and phase equilibria among grain boundary structures. J. Phys. Colloq. 43, 199–213 (1982).

Rottman, C. Theory of phase transitions at internal interfaces. J. Phys. Colloq. 49, 313–326 (1988).

Han, J., Vitek, V. & Srolovitz, D. J. Grain-boundary metastability and its statistical properties. Acta Mater. 104, 259–273 (2016).

Tang, M., Carter, W. C. & Cannon, R. M. Diffuse interface model for structural transitions of grain boundaries. Phys. Rev. B 73, 024102 (2006).

Dillon, S. J., Tang, M., Carter, W. C. & Harmer, M. P. Complexion: a new concept for kinetic engineering in materials science. Acta Mater. 55, 6208–6218 (2007).

Luo, J., Cheng, H., Asl, K. M., Kiely, C. J. & Harmer, M. P. The role of a bilayer interfacial phase on liquid metal embrittlement. Science 333, 1730–1733 (2011).

Cantwell, P. R. et al. Grain boundary complexions. Acta Mater. 62, 1–48 (2014).

Udler, D. & Seidman, D. N. Congruent phase transition at a twist boundary induced by solute segregation. Phys. Rev. Lett. 77, 3379–3382 (1996).

Duscher, G., Chisholm, M. F., Alber, U. & Rühle, M. Bismuth-induced embrittlement of copper grain boundaries. Nat. Mater. 3, 621–626 (2004).

Schweinfest, R., Paxton, A. T. & Finnis, M. W. Bismuth embrittlement of copper is an atomic size effect. Nature 432, 1008–1011 (2004).

Tang, M., Carter, W. C. & Cannon, R. M. Grain boundary transitions in binary alloys. Phys. Rev. Lett. 97, 075502 (2006).

Dillon, S. J., Harmer, M. P. & Luo, J. Grain boundary complexions in ceramics and metals: an overview. JOM 61, 38–44 (2009).

Wang, Z. et al. Atom-resolved imaging of ordered defect superstructures at individual grain boundaries. Nature 479, 380–383 (2011).

Rohrer, G. S. The role of grain boundary energy in grain boundary complexion transitions. Curr. Opin. Solid State Mater. Sci. 20, 231–239 (2016).

Zhou, N., Hu, T. & Luo, J. Grain boundary complexions in multicomponent alloys: Challenges and opportunities. Curr. Opin. Solid State Mater. Sci. 20, 268–277 (2016).

Yu, Z. et al. Segregation-induced ordered superstructures at general grain boundaries in a nickel-bismuth alloy. Science 358, 97–101 (2017).

Frolov, T., Olmsted, D. L., Asta, M. & Mishin, Y. Structural phase transformations in metallic grain boundaries. Nat. Commun. 4, 1899 (2013).

Zhu, Q., Samanta, A., Li, B., Rudd, R. E. & Frolov, T. Predicting phase behavior of grain boundaries with evolutionary search and machine learning. Nat. Commun. 9, 467 (2018).

Carrion, F., Kalonji, G. & Yip, S. Evidence for grain boundary phase transition in a 2D bicrystal. Scr. Metall. 17, 915–918 (1983).

Frolov, T. et al. Grain boundary phases in bcc metals. Nanoscale 10, 8253–8268 (2018).

Chua, A. L., Benedek, N. A., Chen, L., Finnis, M. W. & Sutton, A. P. A genetic algorithm for predicting the structures of interfaces in multi-component systems. Nat. Mater. 9, 418–422 (2010).

Oganov, A. R. & Glass, C. W. Crystal structure prediction using ab initio evolutionary techniques: principles and applications. J. Chem. Phys. 124, 244704 (2006).

Lyakhov, A. O., Oganov, A. R., Stokes, H. T. & Zhu, Q. New developments in evolutionary structure prediction algorithm USPEX. Comput. Phys. Commun. 184, 1172–1182 (2013).

Maksimova, E. L., Shvindlerman, L. S. & Straumal, B. B. Transformation of Σ17 special tilt boundaries to general boundaries in tin. Acta Metall. 36, 1573–1583 (1988).

Rabkin, E., Minkwitz, C., Herzig, C. H. & Klinger, L. Evidence for structural multiplicity of the Σ = 3 incoherent twin boundary in Cu from grain-boundary diffusion measurements. Phil. Mag. Lett. 79, 409–415 (1999).

Divinski, S. V., Edelhoff, H. & Prokofjev, S. Diffusion and segregation of silver in copper Σ5(310) grain boundary. Phys. Rev. B 85, 144104 (2012).

Dehm, G., Edongué, H., Wagner, T., Oh, S. H. & Arzt, E. Obtaining different orientation relationships for Cu films grown on (0001) α-Al2O3 substrates by magnetron sputtering. Z. Metall. Mater. Res. Adv. Techniq. 96, 249–254 (2005).

Freitas, R., Asta, M. & de Koning, M. Nonequilibrium free-energy calculation of solids using LAMMPS. Comput. Mater. Sci. 112, 333–341 (2016).

Freitas, R., Rudd, R. E., Asta, M. & Frolov, T. Free energy of grain boundary phases: atomistic calculations for Σ5(310)[001] grain boundary in Cu. Phys. Rev. Mater. 2, 093603 (2018).

Aramfard, M. & Deng, C. Mechanically enhanced grain boundary structural phase transformation in Cu. Acta Mater. 146, 304–313 (2018).

Khalajhedayati, A., Pan, Z. & Rupert, T. J. Manipulating the interfacial structure of nanomaterials to achieve a unique combination of strength and ductility. Nat. Commun. 7, 10802 (2016).

Phillips, M. A. et al. X-ray microdiffraction: local stress distributions in polycrystalline and epitaxial thin films. Microelectron. Eng. 75, 117–126 (2004).

Dehm, G., Balk, T. J., Edongué, H. & Arzt, E. Small-scale plasticity in thin Cu and Al films. Microelectron. Eng. 70, 412–424 (2003).

Pryor, A., Ophus, C. & Miao, J. A streaming multi-GPU implementation of image simulation algorithms for scanning transmission electron microscopy. Adv. Struct. Chem. Imaging 3, 15 (2017).

Ophus, C. A fast image simulation algorithm for scanning transmission electron microscopy. Adv. Struct. Chem. Imaging 3, 13 (2017).

Plimpton, S. Fast parallel algorithms for short-range molecular dynamics. J. Comput. Phys. 117, 1–19 (1995).

Stukowski, A. Visualization and analysis of atomistic simulation data with OVITO—the open visualization tool. Model. Simul. Mater. Sci. Eng. 18, 015012 (2010).

Peter, N. J. et al. Segregation-induced nanofaceting transition at an asymmetric tilt grain boundary in copper. Phys. Rev. Lett. 121, 255502 (2018).

Foiles, S. M. Evaluation of harmonic methods for calculating the free energy of defects in solids. Phys. Rev. B 49, 14930–14938 (1994).

Gibbs, J. W. The Collected Work of J. William Gibbs Vol. 1 (Longmans, Green and Co., 1928).

Frolov, T. & Mishin, Y. Thermodynamics of coherent interfaces under mechanical stresses. I. Theory. Phys. Rev. B 85, 224106 (2012).

Frolov, T. & Mishin, Y. Thermodynamics of coherent interfaces under mechanical stresses. II. Application to atomistic simulation of grain boundaries. Phys. Rev. B 85, 224107 (2012).

Acknowledgements

We thank G. Richter and his team from the Max Planck Institute for Intelligent Systems for producing the Cu thin films by molecular beam epitaxy. T.F. is grateful to R. Freitas for the help with the free energy calculations. G.D. and T.M. acknowledge financial support from the European Research Council through grant number 787446 GB-CORRELATE. Support for T.F. and R.E.R. was provided under the auspices of the US Department of Energy by Lawrence Livermore National Laboratory under contract DE-AC52-07NA27344. T.F. and R.E.R. were funded by the Laboratory Directed Research and Development Program at Lawrence Livermore National Laboratory under Project Tracking Code number 19-ERD-026.

Author information

Authors and Affiliations

Contributions

T.F., G.D. and C.H.L. supervised the project. T.M. characterized the samples, performed all microscopy measurements and conducted the STEM image simulations. T.M., G.D. and C.H.L. analysed the experimental and simulated microscopy data. T.F. performed GB structure search, data analysis, MD simulations and the thermodynamic analysis. T.F., T.M. and C.H.L. analysed the simulated GB data. T.M., C.H.L., T.F., R.E.R. and G.D. wrote the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Peer review information Nature thanks Eugen Rabkin, Gregory S. Rohrer and the other, anonymous, reviewer(s) for their contribution to the peer review of this work.

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Extended data figures and tables

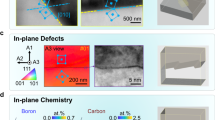

Extended Data Fig. 1 Electron backscatter diffraction characterization of the Cu thin film.

The \([11\bar{1}]\) tilt GBs have been obtained by thin-film deposition of Cu on a (0001)-oriented sapphire substrate. The inverse pole figure shows that all grains are in the ⟨111⟩ orientation with an average grain size of ≤100 μm. The majority of GBs in the film are twin and low-angle GBs (up to 70%), but crucially, Σ7, Σ19b, Σ37c and the corresponding asymmetric boundaries are also present. The most prominent GBs are coloured. The Σ19b GBs are highlighted in red. The white rectangle in the centre shows a position where a TEM specimen has been extracted.

Extended Data Fig. 2 Input GB structures for STEM image simulations.

a, GB energy plotted versus the number of inserted atoms n as a fraction of the (178) GB plane. The red, green and yellow circles indicate the locations of the GB structures shown in b–d, which show the three GB structures used for STEM image simulation, respectively. Each left panel shows the structure along the tilt axis \([11\bar{1}]\), and each right panel shows the structure perpendicular to the tilt axis. The coloured boxes indicate where these structures are located in the energy plot.

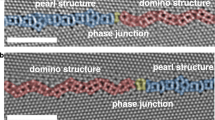

Extended Data Fig. 3 Linking atomic-resolution observations and structure prediction.

a, Aberration-corrected HAADF-STEM image of the symmetric Σ19b (178) \([11\bar{1}]\) pearl phase. Its structural unit is highlighted in the inset. b, Colour coding of the experimental GB structure based on atomic column peak intensities. c–e, Simulated STEM images of the predicted GB structures by USPEX for a sample thickness of 22 nm. Colour coding as in b. c, Lowest-energy structure with GB energy of 0.835 J m−2 and n = 0; d, medium-energy GB structure with 0.932 J m−2 and n = 0.5; and e, high-energy GB structure with 1.023 J m−2 and n = 0.5. The scale bar is 1 nm in all images.

Extended Data Fig. 4 Asymmetric GB structures.

a, b, Ground-state pearl (a) and metastable domino (b) structures of the asymmetric boundary at 0 K. The two structures have the same number of atoms and correspond to two different translations of the bulk grains relative to each other.

Extended Data Fig. 5 Asymmetric GB transformation at 600 K.

a, Nucleation of a pearl GB phase at the open surface (left) of the asymmetric GB at 600 K. b, Asymmetric pearl GB phase after the transformation at 600 K is complete. The boundary remains asymmetric.

Extended Data Fig. 6 Asymmetric GB transformation at 700 K.

a and b show the nucleation of the pearl GB phase from the open surface on the left of the simulation cell annealed at 700 K. c and d from the right. e, The initially asymmetric domino structure transformed into a symmetric pearl phase in MD at 700 K after the transformation is complete.

Extended Data Fig. 7 Stress-dependent GB excess enthalpies.

0 K calculations of GB excess enthalpies γdomino and γpearl to estimate stresses and strains required to stabilize the domino phase and achieve equilibrium coexistence in the model. GB excess energy curves cross at: a, lateral strain \({\varepsilon }_{11}^{\ast }\) = 2%; b, tensile stress \({\sigma }_{33}^{\ast }\) = 5 GPa; and c, shear stress parallel to the GB along the tilt axis \({\sigma }_{23}^{\ast }\) = 440 MPa. [U]N, [V]N and [B]N are the excess GB energy, volume and shear, respectively.

Extended Data Fig. 8 GB free energies.

a, GB free energies of domino and pearl phases as functions of temperature at zero bulk stress calculated using harmonic and quasi-harmonic approximations. b, The GB free energy difference γdomino − γpearl as a function of temperature decreases but remains positive suggesting that at ambient pressure the domino phase remains metastable in our model. These calculations are consistent with domino to pearl transformations simulated directly with MD. They also show that in the model the relative stability of the domino phase improves with temperature since the GB free energy difference decreases by about 30% relative to 0 K.

Extended Data Fig. 9 Finite temperature GB phase transformations under stress.

MD simulations of GB phase transformations and equilibrium coexistence at 500 K under ambient conditions (a, b), tensile stress (c) and shear stress (d). a, To avoid hysteresis due to the nucleation barrier we start with a two-phase state (a) and monitor the direction of the GB phase junction migration. b, At ambient conditions the pearl phase grows and the junction moves to the left. c, Under tensile stress of 3.95 GPa the domino phase becomes thermodynamically more stable, it grows at the expense of the pearl phase and the junction moves to the right. d, Under a shear stress of 342 MPa parallel to the GB plane in the direction parallel to the tilt axis the domino phase also becomes more stable and grows. The black arrow indicates the initial position of the GB phase junction, while the green line shows the final position. We performed similar simulations at different tensile and shear stresses and conclude that in the model the equilibrium coexistence between the pearl and domino phases at this temperature of 500 K can be achieved at around 3.3 GPa tension or within the range 200–350 MPa for shear stress. The simulations of equilibrium coexistence confirm that pearl and domino are examples of GB phases. The MD simulations ran for 200 ns to 400 ns.

Source data

Rights and permissions

About this article

Cite this article

Meiners, T., Frolov, T., Rudd, R.E. et al. Observations of grain-boundary phase transformations in an elemental metal. Nature 579, 375–378 (2020). https://doi.org/10.1038/s41586-020-2082-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41586-020-2082-6

This article is cited by

-

Structural transition and migration of incoherent twin boundary in diamond

Nature (2024)

-

Computed entropy spectra for grain boundary segregation in polycrystals

npj Computational Materials (2024)

-

Incommensurate grain-boundary atomic structure

Nature Communications (2023)

-

Atomic motifs govern the decoration of grain boundaries by interstitial solutes

Nature Communications (2023)

-

Automatic identification of crystal structures and interfaces via artificial-intelligence-based electron microscopy

npj Computational Materials (2023)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.