Abstract

In this study, the electrochemical polarization tests were performed on tensioned and non-tensioned CUSTOM 450 specimens in a 3.5 wt% NaCl solution to investigate pitting potential and stable pit initiation time. A potentiodynamic test was conducted to determine the exact amount of pitting potentials. According to the potentiostatic tests, a relation between applied potential and the stable pit initiation time was obtained. Concerning this relation, stable pitting time can be predicted without experimental works. Optical microscopy was used to evaluate the shape of the pits. Tensile stress led the pit to experience the “pit to crack” step. The corrosion rate of samples was studied by the determination of mass loss. Mass loss measurements and current density–time curve in potentiostatic tests demonstrated the rate of pitting corrosion decreased as time passed. Finally, the depth of the pits was measured by the eddy current technique. The results showed that tensile stress facilitated deeper pit development.

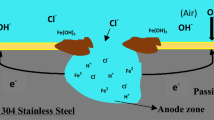

Graphic Abstract

Similar content being viewed by others

References

J. Tian, X. Liu, S. Chen, Fracture analysis on compressor blades. Int. J. Fatigue 13(4), 333–336 (1991)

N.S. Xi, P.D. Zhong, H.Q. Huang, H. Yan, C.H. Tao, Failure investigation of blade and disk in first stage compressor. Eng. Fail. Anal. 7(6), 385–392 (2000)

E. Poursaeidi, A.M. Niaei, M. Arablu, A. Salarvand, Experimental investigation on erosion performance and wear factors of custom 450 steel as the first row blade material of an axial compressor. Int. J. Surf. Sci. Eng. 11(2), 85–99 (2017)

E. Poursaeidi, A. Babaei, M.M. Arhani, M. Arablu, Effects of natural frequencies on the failure of R1 compressor blades. Eng. Fail. Anal. 25, 304–315 (2012)

R. Derakhshandeh-Haghighi, Metallurgical analysis and simulation of a service-fractured compressor blade made of ASTM S45000 alloy. J. Fail. Anal. Prev. 17(3), 522–528 (2017)

O. Pedram, E. Poursaeidi, Total life estimation of a compressor blade with corrosion pitting, SCC and fatigue cracking. J. Fail. Anal. Prev. 18(2), 423–434 (2018)

E. Poursaeidi, H. Bakhtiari, Fatigue crack growth simulation in a first stage of compressor blade. Eng. Fail. Anal. 45, 314–325 (2014)

H. Chae, H. Wang, M. Hong, W.C. Kim, J.G. Kim, H. Kim, S.Y. Lee, Stress corrosion cracking of a copper pipe in a heating water supply system. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00386-0

American Society for Metals (ASM), Metals Handbook, Corrosion, vol. 13, 9th edn. (Metals Park, Ohio, 1987)

M. Jayalakshmi, V.S. Muralidharan, Empirical and deterministic models of pitting corrosion—an overview. Corros. Rev. 14(3–4), 375–402 (1996)

E. Poursaeidi, O. Pedram, An outrun competition of corrosion fatigue and stress corrosion cracking on crack initiation in a compressor blade. Int. J. Eng. Trans. B Appl. 27(5), 785 (2013)

A.S.T.M. Standard, Standard guide for examination and evaluation of pitting corrosion (2005)

C. Punckt, M. Bölscher, H.H. Rotermund, A.S. Mikhailov, L. Organ, N. Budiansky, J.R. Scully, J.L. Hudson, Sudden onset of pitting corrosion on stainless steel as a critical phenomenon. Science 305(5687), 1133–1136 (2004)

W. Tian, N. Du, S. Li, S. Chen, Q. Wu, Metastable pitting corrosion of 304 stainless steel in 3.5% NaCl solution. Corros. Sci. 85, 372–379 (2014)

M.A. Amin, Metastable and stable pitting events on Al induced by chlorate and perchlorate anions—polarization, XPS and SEM studies. Electrochim. Acta 54(6), 1857–1863 (2009)

C. Vasilescu, S.I. Drob, P. Osiceanu, P. Drob, J.M.C. Moreno, S. Preda, S. Ivanescu, E. Vasilescu, Surface analysis, microstructural, mechanical and electrochemical properties of new Ti–15Ta–5Zr alloy. Met. Mater. Int. 21(2), 242–250 (2015)

S.W. Baek, J.K. Lee, J.J. Kim, K.J. Kim, Pitting failure of copper pipings for emergency fire sprinkler in ground water. Met. Mater. Int. 21(3), 479–484 (2015)

D. Ifezue, Chloride pitting of steam generator boiler coils. J. Fail. Anal. Prev. 17(5), 831–837 (2017)

T.S.L. Wijesinghe, D.J. Blackwood, Real time pit initiation studies on stainless steels: the effect of sulphide inclusions. Corros. Sci. 49(4), 1755–1764 (2007)

D.K. Hamilton, T. Wilson, Three-dimensional surface measurement using the confocal scanning microscope. Appl. Phys. B 27(4), 211–213 (1982)

W.B. Amos, J.G. White, How the confocal laser scanning microscope entered biological research. Biol. Cell 95(6), 335–342 (2003)

B.V.R. Tata, B. Raj, Confocal laser scanning microscopy: applications in material science and technology. Bull. Mater. Sci. 21(4), 263–278 (1998)

M.B. Dürrenberger, S. Handschin, B. Conde-Petit, F. Escher, Visualization of food structure by confocal laser scanning microscopy (CLSM). LWT Food Sci. Technol. 34(1), 11–17 (2001)

M. Jasiczek, J. Kaczorowski, E. Kosieniak, M. Innocenti, A new approach to characterization of gas turbine components affected by pitting corrosion. J. Fail. Anal. Prev. 12(3), 305–313 (2012)

M.S. Hong, S.H. Kim, S.Y. Im, J.G. Kim, Effect of ascorbic acid on the pitting resistance of 316L stainless steel in synthetic tap water. Met. Mater. Int. 22(4), 621–629 (2016)

E.S.M. Sherif, F.H. Latief, H.S. Abdo, N.H. Alharthi, Electrochemical and spectroscopic study on the corrosion of Ti-5Al and Ti- 5Al-5Cu in chloride solutions. Met. Mater. Int. 25(6), 1511–1520 (2019)

Avanindra, Multifrequency eddy current signal analysis. Master of Science Thesis, Iowa State University (1997)

D.C. Copley, Eddy-current imaging for defect characterization, in Review of Progress in Quantitative Nondestructive Evaluation, vol. 2A, ed. by D.O. Thompson, D.E. Chimenti (Springer, Boston, 1983), pp. 1527–1540

V.N. Uchanin, V.N. Tsirg, Detection of hidden corrosion damage in aviation structures by the eddy current method. Mater. Sci. 26(4), 475–477 (1991)

B.R. Groshong, G.L. Bilbro, W.E. Snyder, Eddy current image restoration by constrained gradient descent. J. Nondestr. Eval. 10(4), 127–137 (1991)

J.C. Moulder, M.W. Kubovich, E. Uzal, J.H. Rose, Pulsed eddy-current measurements of corrosion-induced metal loss: theory and experiment. Rev. Prog. Quant. Nondestr. Eval. 14, 2065–2072 (1995)

R. Satveli, J.C. Moulder, J.H. Rose, Eddy-current detection of pitting corrosion in aircraft lap-splices. Rev. Prog. Quant. Nondestr. Eval. 15, 1755–1762 (1996)

J.A. Bieber, C.C. Tai, J.C. Moulder, Quantitative assessment of corrosion in aircraft structures using scanning pulsed eddy current. Rev. Prog. Quant. Nondestr. Eval. 17, 315–322 (1998)

B.A. Auld, J.C. Moulder, Review of advances in quantitative eddy current nondestructive evaluation. J. Nondestr. Eval. 18(1), 3–36 (1999)

D. Lamtenzan, M. Lozev, G. Washer, Detection and sizing of cracks in structural steel using the eddy current method (No. FHWA-RD-00-018). Turner-Fairbank Highway Research Center (2000)

V.M. Uchanin, Eddy-current flaw detection in structural elements. Mater. Sci. 42(4), 494–501 (2006)

V.P. Lunin, A.G. Zhdanov, D.Y. Lazutkin, A neural-network classifier of flaws for multifrequency eddy-current tests of heat-exchange pipes. Russ. J. Nondestr. Test. 43(3), 163–169 (2007)

H. Shaikh, N. Sivaibharasi, B. Sasi, T. Anita, B.P.C. Rao, T. Jayakumar, R.K. Dayal, B. Raj, Effect of carbon content on eddy current response to sensitization and intergranular corrosion in simulated heat-affected zone of austenitic stainless steel. Weld. World 56(5–6), 44–53 (2012)

A. da Cunha Rocha, M.C.L. Areiza, S.S. Tavares, J.M.A. Rebello, Microstructural evaluation of a lean duplex UNS S32304—X-ray diffraction and scanning electron microscopy techniques correlated with eddy current testing, in TMS 2014: 143rd Annual Meeting and Exhibition (Springer, Cham, 2014), pp. 741–749

H.S. Shim, M.S. Choi, D.H. Lee, D.H. Hur, A prediction method for the general corrosion behavior of Alloy 690 steam generator tube using eddy current testing. Nucl. Eng. Des. 297, 26–31 (2016)

A. Ziouche, M. Zergoug, N. Boucherrou, H. Boudjellal, M. Mokhtari, S. Abaidia, Pulsed eddy current signal analysis of ferrous and non-ferrous metals under thermal and corrosion solicitations. Russ. J. Nondestr. Test. 53(9), 652–659 (2017)

V.A. Golovin, N.V. Pechnikov, S.B. Kapranov, N.N. Davidenko, A.M. Nemytova, P.D. Bachinskii, V.A. Trembovler, Using an eddy-current technique for studying local corrosion and scale formation on the walls of heat-exchanger tubes. Prot. Met. Phys. Chem. Surf. 52(7), 1197–1204 (2016)

V.A. Golovin, N.V. Pechnikov, V.A. Shchelkov, A.Y. Tsivadze, Determination of the life cycle of heat-exchange tubes of vapor condensers on the basis of statistical analysis of local pitting corrosion according to data of eddy current testing. Prot. Met. Phys. Chem. Surf. 54(6), 1221–1232 (2018)

A. Mansur, Modeling of mechanical properties of ceramic-metal composites for armor applications, Doctoral dissertation, University of Ottawa (2011)

A. Midha, D.E. Wert, Martensitic age-hardenable stainless steel. Adv. Mater. Process. 169(9), 30–33 (2011)

W. Tian, S. Li, N. Du, S. Chen, Q. Wu, Effects of applied potential on stable pitting of 304 stainless steel. Corros. Sci. 93, 242–255 (2015)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pedram, O., Mollapour, Y., Shayani-jam, H. et al. Pitting Corrosion Behavior of CUSTOM 450 Stainless Steel Using Electrochemical Characterization. Met. Mater. Int. 27, 4346–4356 (2021). https://doi.org/10.1007/s12540-020-00640-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00640-w