Abstract

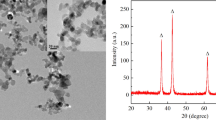

Transient liquid phase-like soldering technique has been successfully applied to prepare lead-free solder joints at 230 °C. Multiple interlayers of tin thin films in combination with a Sn-3.0Ag-0.5Cu (SAC305) solder paste have been used as filler for joining. Microstructural analysis was carried out by electron microscopy and energy-dispersive spectroscopy. For interlayer containing samples (Cu-Sn-SAC305-Sn-Cu), interfacial intermetallics layers found to be more homogeneous compared to the samples without interlayers (Cu-SAC305-Cu). Quality of the joints has been investigated nondestructively by ultrasonic method. On measuring the electrical resistivity by four-probe method, Cu-Sn-SAC305-Sn-Cu solder joint shows lower electrical resistivity compared to that of the Cu-SAC305-Cu solder joint, wherein nonlinear ultrasonic parameters confirm the superiority of former over later.

Similar content being viewed by others

References

A. Kar, M. Ghosh, B.S. Majumdar, R.N. Ghosh, and A.K. Ray, Interfacial Microstructure, Shear Strength and Electrical Conductivity of Sn-3.5Ag-0.5In/Cu Lead Free Soldered Joints, Mater. Tech., 2007, 22(3), p 161–165

W.C. Luo, C.E. Ho, J.Y. Tsai, Y.L. Lin, and C.R. Kao, Solid-State Reactions Between Ni and Sn-Ag-Cu Solders with Different Cu Concentrations, Mater. Sci. Eng., A, 2005, 396(1), p 385–391

S. Cheng, C.M. Huang, and M. Pecht, A Review of Lead-Free Solders for Electronics Applications, Microelect. Reliab., 2017, 75, p 77–95

R. Berni, M. Catelani, C. Fiesoli, and V.L. Scarano, A Comparison of Alloy-Surface Finish Combinations Considering Different Component Package Types and Their Impact on Soldering Reliability, IEEE Trans. Reliab., 2016, 65(1), p 272–281

R. Coyle, K. Sweatman, and B. Arfaei, Thermal Fatigue Evaluation of Pb-Free Solder Joints: Results, Lessons Learned, and Future Trends, J. Miner. Metals Mater. Soc., 2015, 67(10), p 2394–2415

A.M. Erer, O. Uyanik, and Y. Türen, Influence of Bismuth (Bi) Addition on Wetting Characteristics of Sn-3Ag-05Cu Solder Alloy on Cu Substrate, JESTECH, 2018, 21(6), p 1159–1163

M.I.I. Ramli, M.S.S. Yusof, M.A.A.M. Salleh, R.M. Said, and K. Nogita, Influence of Bi Addition on Wettability and Mechanical Properties of Sn-0.7Cu Solder Alloy, Solid State Phenomena. Trans. Tech. Publ., 2018, 273, p 27–33

X. Hongyan and Y. Zhanfu, Interfacial Reaction Kinetics Between Liquid Sn-Ag-Cu Alloy and Cu Substrate, R. Metals Mater. Eng., 2014, 43, p 2893–2897

M. Yang, Y.H. Koa, J.H. Bang, T.S. Kim, C.W. Lee, and M. Li, Effects of Ag Addition on Solid-State Interfacial Reactions Between Sn-Ag-Cu Solder and Cu Substrate, Mater. Charact., 2017, 124, p 250–259

A.T. Tan, A.W. Tan, and F. Yusof, Influence of Nanoparticle Addition on the Formation and Growth of Intermetallics Compounds (IMCs) in Cu/Sn-Ag-Cu/Cu Solder Joint During Different Thermal Conditions, Sci. Technol. Adv. Mater., 2015, 033505(16), p 18

M. Ghosh, A. Kar, S.K. Das, and A.K. Ray, Aging Characteristics of Sn-Ag Eutectic Solder Alloy with the Addition of Cu, In, and Mn, Metal. Mater. Trans. A, 2009, 40(10), p 2369–2376

J.F. Li, P.A. Agyakwa, and C.M. Johnson, Interfacial Reaction in Cu/Sn/Cu System During the Transient Liquid Phase Soldering Process, Acta Mater., 2011, 59, p 1198–1211

R. Kolenak, R. Augustin, M. Martinkovic, and M. Chachula, Comparison Study of SAC405 and SAC405 + 0.1% Al Lead Free Solders, Solder. Surf. Mount Technol., 2013, 25(3), p 175–183

J.K. Kivilahti, The Chemical Modeling of Electronic Materials and Interconnections, JOM, 2002, 54(12), p 52–57

T. Xu, X. Hu, Y. Li, and X. Jiang, The Growth Behavior of Interfacial Intermetallic Compound Between Sn-3.5Ag-0.5Cu Solder and Cu Substrate Under Different Thermal-Aged Conditions, J. Mater. Sci. Mater. Electr., 2017, 28(24), p 18515–18528

C. Yang, F. Le, and S.W.R. Lee, Experimental Investigation of the Failure Mechanism of Cu–Sn Intermetallic Compounds in SAC305 Solder Joints, Microelectron. Reliab., 2016, 62, p 130–140

T. Egar, M. Sadeghian, A. Ekrami, and R. Jamshidi, Transient Liquid Phase Bonding of 304 Stainless Steel Using a Co-Based Interlayer, Sci. Technol. Weld. Join., 2017, 22(8), p 666–672

T. Laurila, J. Hurtig, V. Vuorinen, and J.K. Kivilahti, Effect of Ag, Fe, Au and Ni on the Growth Kinetics of Sn-Cu Intermetallic Compound Layers, Microelec. Reliab., 2009, 49, p 242–247

P.Y. Chia, A.S.M.A. Haseeb, and S.H. Mannan, Reactions in Electrodeposited Cu/Sn and Cu/Ni/Sn Nanoscale Multilayers for Interconnects, Materials, 2016, 9(6), p 430

Q.V. Bui, N.D. Nam, J.W. Yoon, D.H. Choi, A. Kar, J.G. Kim, and S.B. Jung, Effect of Gold on the Corrosion Behavior of an Electroless Nickel/Immersion Gold Surface Finish, J. Electr. Mater., 2011, 40(9), p 1937–1942

L. Zhang, Z. Liu, F. Yang, and S. Zhong, Cu/SnAgCu/Cu TLP with Different Thicknesses for 3D IC, Solder. Surf. Mount. Tech., 2017, 29(3), p 151–155

L.M. Lee, and A.A. Mohamad, Interfacial Reaction of Sn-Ag-Cu Lead-Free Solder Alloy on Cu: A Review. Hindawi Publishing Corporation. Adv. Mater. Sci. Eng. 2013, 2013, p. 1–11

J. Lienig, and M. Thiele, Fundamentals of Electromigration-Aware Integrated Circuit Design, Springer International Publishing AG 2018, ISBN 978-3-319-73557-3

T. An and F. Qin, Effect of the Intermetallic Compound Microstructure on the Tensile Behaviour of Sn3.0Ag0.5Cu/Cu Solder Joint Under Various Strain Rates, Microelectron. Reliab., 2014, 54, p 932–938

S. Shang, A. Kunwar, Y. Wang, L. Qu, H. Ma, and Y. Wang, Growth Behavior of Preferentially Scalloped Intermetallic Compounds at Extremely Thin Peripheral Sn/Cu Interface, J. Mater. Sci.: Mater. Electr., 2019, 30(3), p 2872–2887

Y. Tang, S. Luo, G. Li, Z. Yang, and C. Hou, Ripening Growth Kinetics of Cu6Sn5 Grains in Sn-3.0Ag-0.5Cu-xTiO2/Cu Solder Joints During the Reflow Process, J. Electron. Packag., 2018, 140(1), p 011003

S. Annuar, R. Mahmoodian, M. Hamdi, and K.N. Tu, Intermetallic Compounds in 3D Integrated Circuits Technology: A Brief Review, Sci. Technol. Adv. Mater., 2017, 18(1), p 1–11

S. Shang, A. Kunwar, J. Yao, Y. Wang, N. Zhao, M. Huang, and H. Ma, All-Round Suppression of Cu6Sn5 Growth in Sn/Cu Joints by Utilizing TiO2 Nanoparticles, J. Mater. Sci.: Mater. Electron., 2018, 29(18), p 15966–15972

F. Xing, Q. Shang, Y. Lu, J. Liang, and X. Qiu, Intermetallic Compounds Growth Suppression in ZSCB Solder with RE Addition on Cu Substrate, J. Alloys Compd., 2016, 666, p 122–130

Y. Huang, Z. Xiu, G. Wu, Y. Tian, P. He, X. Gu, and W. Long, Improving Shear Strength of Sn-3.0Ag-0.5Cu/Cu Joints and Suppressing Intermetallic Compounds Layer Growth by Adding Graphene Nanosheets, Mater. Lett., 2016, 169, p 262–264

D. Yan, B.W. Drinkwater, and S.A. Neild, Measurement of the Ultrasonic Non Linearity of Kissing Bonds in Adhesive Joints, NDT&E Intern., 2009, 42(5), p 459–466

M.S. Park, S.L. Gibbons, and R. Arroyave, Phase-Field Simulations of Intermetallic Compound Evolution in Cu/Sn Solder Joints Under Electromigration, Acta Mater., 2013, 61, p 7142–7154

W.G. Zhai, X.M. Zhao, X.F. Li, M.J. Fan, X.H. Xu, X. Wang et al., Effect of Ce on Resistivity of Sn-3.8Ag-0.7Cu-xCe Lead-Free Solders, Phys. Chem. Liq., 2016, 54, p 37–41

T.I. Shih, Y.C. Lin, J.G. Duh, Tom Hsu, and W.S. Wu, Electrical Measurement of a Lead-Free Solder Assembly After Environmental Tests by SEM Internal Probing, JOM, 2007, 59(7), p 32–37

A. Yakymovych, V. Sklyarchuk, Y. Plevachuk, and B. Sokoliuk, Viscosity and Electrical Conductivity of the Liquid Sn-3.8Ag-0.7Cu Alloy with Minor Co Admixtures, J. Mater. Eng. Perform., 2016, 25(10), p 4437–4443

M.A.A. Mohd Salleh, S.D. McDonald, C.M. Gourlay, H. Yasuda, and K. Nogita, Suppression of Cu6Sn5 in TiO2 Reinforced Solder Joints After Multiple Reflow Cycles, Mater. Des., 2016, 108, p 418–428

Acknowledgments

Authors thank the DST-SERB, Govt. of India for funding this research (Grant Ref. No. SB/FTP/ETA-136/2012, dated 20/05/2013) and also the Director, JBNSTS, Kolkata, for her continuous encouragement and support. Dr. Amit Kumar Chakraborty acknowledges the Centre of Excellence in Advanced Materials at NIT Durgapur (Grant Ref. No. AC/MHRD/TEQIP-II/CoE/2013, dated 4th April, 2013, of the MHRD, Govt. of India).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Char, M., Chakraborty, A.K., Metya, A.K. et al. Retardation Effect of Tin Multilayer on Sn-3.0Ag-0.5Cu (SAC305)-Based Solder Joint Interface. J. of Materi Eng and Perform 29, 2305–2315 (2020). https://doi.org/10.1007/s11665-020-04730-z

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04730-z