Abstract

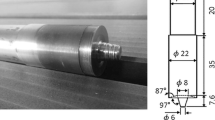

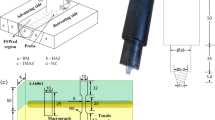

In this paper, friction stir spot welding of 2-mm-thick AA 1060 Al to T2 Cu is conducted. The effects of dwell time, tool rotational speed and shoulder plunge depth on tensile shear failure load (TSFL) are investigated. A quadratic regression model is proposed to fit the relationship between TSFL of the joint and the welding process parameters. The analysis-of-variance results show that the rotational speed is the most significant factor affecting the TSFL. Joint fabricated at the low rotational speed is weak-bonded by discontinuous intermetallic layers due to the insufficient heat input. Increasing the rotational speed can improve the TSFL by promoting intermetallics formation at the interface, while an excessive increase in rotational speed results in formation of microcrack at the interface, which seriously compromises the tensile property of the joint. Shoulder plunge depth, tool rotational speed and dwell time of 0.1 mm, 2371 r/min and 4.96 s, respectively, were identified as the optimal combination of welding process parameters. Results of microstructure characterization show that the joint produced at the optimized process parameters is well metallurgically bonded by a 1.9-μm-thick laminated intermetallics layer which comprises CuAl and CuAl2 sublayers. Result of fracture path reveals that the fracture firstly extends along the interfacial CuAl2 layer by a brittle mode and then propagates through the aluminum matrix in the stir zone by a ductile mode.

Similar content being viewed by others

References

T.A. Mai and A.C. Spowage, Characterisation of Dissimilar Joints in Laser Welding of Steel–Kovar, Copper–Steel and Copper–Aluminium, Mater. Sci. Eng. A, 2004, 374, p 224–233

C. Otten, U. Reisgen, and M. Schmachtenberg, Electron Beam Welding of Aluminum to Copper: Mechanical Properties and Their Relation to Microstructure, Weld. World, 2016, 60, p 21–31

Y. Li, Y. Zhang, J. Bi, and Z. Luo, Impact of Electromagnetic Stirring Upon Weld Quality of Al/Ti Dissimilar Materials Resistance Spot Welding, Mater. Des., 2015, 83, p 577–586

Y. Ding, Z. Shen, and A.P. Gerlich, Refill Friction Stir Spot Welding of Dissimilar Aluminum Alloy and AlSi Coated Steel, J. Manuf. Process., 2017, 30, p 353–360

R. Heideman, C. Johnson, and S. Kou, Metallurgical Analysis of Al/Cu Friction Stir Spot Welding, Sci. Technol. Weld. Join., 2013, 15, p 597–604

M. Shiraly, M. Shamanian, and M.R. Toroghinejad, Effect of Tool Rotation Rate on Microstructure and Mechanical Behavior of Friction Stir Spot-Welded Al/Cu Composite, J. Mater. Eng. Perform., 2014, 23, p 413–420

M.P. Mubiayi and E.T. Akinlabi, Friction Stir Spot Welding Between Copper and Aluminium: Microstructural Evolution, in Proceedings of the International MultiConference of Engineers and Computer Scientists, Vol II, IMECS 2015, 18–20 March 2015, Hong Kong.

R. Koganti, C. Karas, A. Joaquin, D. Henderson, M. Zaluzec, and A. Caliskan. Metal inert gas (MIG) welding process optimization for joining aluminum sheet material using OTC/DAIHEN equipment, in Proceedings of IMECE’03, 15–21 November, ASME International Mechanical Engineering Congress, Washington, DC, 2003, p 409–425.

K.Y. Benyounis, A.G. Olabi, and M.S.J. Hashmi, Multi-response Optimization of CO2 Laser-Welding Process of Austenitic Stainless Steel, Opt. Laser Technol., 2008, 40, p 76–87

F. Sarsılmaz and U. Çaydaş, Statistical Analysis on Mechanical Properties of Friction-Stir-Welded AA 1050/AA 5083 Couples, Int. J. Adv. Manuf. Technol., 2009, 43, p 248–255

S.L. Ferreira, R.E. Bruns, H.S. Ferreira et al., Box–Behnken Design: An Alternative for the Optimization of Analytical methods, Anal. Chim. Acta, 2007, 597, p 179–186

N. Aslan and Y. Cebeci, Application of Box–Behnken Design and Response Surface Methodology for Modeling of Some Turkish Coals, Fuel, 2007, 86, p 90–97

N.K. Nguyen and J.J. Borkowski, New 3-Level Response Surface Designs Constructed from Incomplete Block Designs, J. Stat. Plan. Inference, 2008, 138, p 294–305

W. Safeen, S. Hussain, A. Wasim, M. Jahanzaib, H. Aziz, and H. Abdalla, Predicting the Tensile Strength, Impact Toughness, and Hardness of Friction Stir-Welded AA6061-T6 Using Response Surface Methodology, Int. J. Adv. Manuf. Technol., 2016, 87, p 1765–1781

A.H. Plaine, A.R. Gonzalez, U.F.H. Suhuddin, J.F. dos Santos, and N.G. Alcaˆntara, Process Parameter Optimization in Friction Spot Welding of AA5754 and Ti6Al4V Dissimilar Joints Using Response Surface Methodology, Int. J. Adv. Manuf. Technol., 2016, 85, p 1575–1583

A.K. Lakshminarayanan, V.E. Annamalai, and K. Elangovan, Identification of Optimum Friction Stir Spot Welding Process Parameters Controlling the Properties of Low Carbon Automotive Steel Joints, J. Mater. Res. Technol., 2015, 4, p 262–272

M.M.A. Khan, L. Romoli, M. Fiaschi, G. Dini, and F. Sarri, Experimental Investigation on Laser Beam Welding of Martensitic Stainless Steels in a Constrained Overlap Joint Configuration, J. Mater. Process. Technol., 2010, 210, p 1340–1353

L. Zhou, G.H. Li, R.X. Zhang, W.L. Zhou, W.X. He, Y.X. Huang, and X.G. Song, Microstructure Evolution and Mechanical Properties of Friction Stir Spot Welded Dissimilar Aluminum–Copper Joint, J. Alloys Compd., 2019, 775, p 372–382

P. Xue, B.L. Xiao, and Z.Y. Ma, Effect of Interfacial Microstructure Evolution on Mechanical Properties and Fracture Behavior of Friction Stir-Welded Al-Cu Joints, Metall. Mater. Trans. A, 2015, 46, p 3091–3103

S. Datta, A. Bandyaopadhyay, and P.K. Pal, Modeling and Optimization of Features of Bead Geometry Including Percentage Dilution in Submerged Arc Welding using Mixture of Fresh Flux and Fused Slag, Int. J. Adv. Manuf. Technol., 2008, 36, p 1080–1090

Y.K. Yang, M.T. Chuang, and S.S. Lin, Optimization of Dry Machining Parameters for High-purity Graphite in End Milling Process via Design of Experiments Methods, J. Mater. Process. Technol., 2009, 209, p 4395–4400

Acknowledgments

The research was sponsored by the Natural Science Foundation of Shandong Province (ZR2016EEM43).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, G.H., Zhou, L., Shu, F.Y. et al. Statistical and Metallurgical Analysis of Dissimilar Friction Stir Spot Welded Aluminum/Copper Metals. J. of Materi Eng and Perform 29, 1830–1840 (2020). https://doi.org/10.1007/s11665-020-04729-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04729-6