Abstract

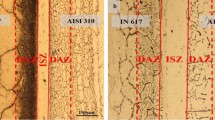

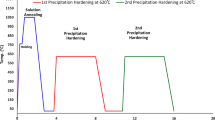

Transient liquid phase (TLP) bonding of 304L austenitic stainless steel was carried out using MBF-20 interlayer at 1070 °C with different holding times. The effect of bonding time on the microstructure and corrosion resistance of the TLP bonded samples was investigated aiming to obtain the optimal bonding time. The results showed that isothermal solidification was completed within 45 min at 1070 °C and shorter holding times gave rise to the formation of intermetallic compounds at the joint centerline. It was found that the solidification sequence in the joint region is as follows: (1) isothermal solidification of γ solid solution, (2) formation of ternary eutectic of γ + Ni boride + Cr boride, and (3) formation of ternary eutectic of γ + Ni boride + Ni–Si–B compound in the athermally solidified zone. Final stage of the phase formation at the joint centerline was the precipitation of Ni3Si particles in the vicinity of eutectic microconstituents via a solid state transformation. Extensive Cr-rich borides were formed in the diffusion affected zone as a result of B diffusion into the base metal during bonding process. Corrosion behavior of the TLP bonded samples was studied in 3.5% NaCl solution. The joint corrosion resistance was improved with the increase of the bonding time to 30 min and then decreased when the holding time was prolonged.

Graphic Abstract

Similar content being viewed by others

References

M.F. Mcguire, Stainless Steel for Design Engineers (The Materials Information Society, Material Park, 2008)

J. Hilkes, K. Bekkers, Welding duplex stainless steel. Weld. J. 74(11), 51–54 (1995)

R. Jamshidi Lamjiri, A. Ekrami, Transient liquid diffusion bonding of AISI304 stainless steel with a nickel base interlayer. Defect. Diffus. Forum 380, 48–54 (2017)

G.O. Cook, C.D. Sorensen, Overview of transient liquid phase and partial transient liquid phase bonding. J. Mater. Sci. 46, 5305–5323 (2011)

D. Duvall, W.A. Owczarski, D.F. Paulonis, TLP boding: a new method for joining heat resistant alloys. Weld J. 53, 203–214 (1974)

C.W. Sinclair, Modeling transient liquid phase bonding in multicomponent systems. J. Phase Equilib. 20, 361–369 (1999)

W.F. Gale, D.A. Butts, Transient liquid phase bonding. Sci. Technol. Weld. J. 9(4), 283–300 (2004)

A. Fazaeli, A. Ekrami, A.H. Kokabi, Microstructure and mechanical properties of dual phase steels, with different martensite morphology, produced during TLP bonding of a low C–Mn steel. Met. Mater. Int. 22(5), 856–862 (2016)

B. Binesh, A. Jazayeri Gharehbagh, Transient liquid phase bonding of IN738LC/MBF-15/IN738LC: solidification behavior and mechanical properties. J. Mater. Sci. Technol. 32, 1137–1151 (2016)

S. Roh, Ch. Lee, Formation of secondary phases and their effect on the mechanical properties of joints formed by TLP bonding using Fe–B–Si insert metal in duplex stainless steel. Met. Mater. Int. 25(2), 425–438 (2019)

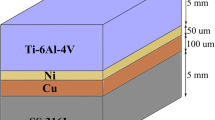

E. Norouzi, M. Atapour, M. Shamanian, A. Allafchian, Effect of bonding temperature on the microstructure and mechanical properties of Ti–6Al–4V to AISI 304 transient liquid phase bonded joint. Mater. Des. 99, 543–551 (2016)

O.A. Idowu, N.L. Richards, M.C. Chaturvedi, Effect of bonding temperature on isothermal solidification rate during transient liquid phase bonding of Inconel 738LC superalloy. Mater. Sci. Eng. A 397, 98–112 (2005)

W. Jiang, J. Gong, S.T. Tu, A new cooling method for vacuum brazing of a stainless steel plate-fin structure. Mater. Des. 31, 648–653 (2010)

R. Abdolvand, M. Atapour, M. Shamaniana, A. Allafchian, The effect of bonding time on the microstructure and mechanical properties of transient liquid phase bonding between SAF 2507 and AISI 304. J. Manuf. Process. 25, 172–180 (2017)

M. Jafari, M. Rafiei, H. Mostaan, Effect of solidification mode on microstructure and mechanical properties of AISI420 steel to SAF2507 steel dissimilar joint produced by transient liquid phase. Met. Mater. Int. (2019). https://doi.org/10.1007/s12540-019-00406-z

C.L. Ou, D.W. Liaw, Y.C. Du, R.K. Shiue, Brazing of 422 stainless steel using the AWS classification BNi-2 braze alloy. J. Mater. Sci. 41, 6353–6361 (2006)

M. Mohammadi, A. Ekrami, Microstructure and mechanical properties of pure Cu interlayer TLP joints of 304 stainless steel to dual phase steel. J. Mater. Process. Technol. 275, 116276 (2020). https://doi.org/10.1016/j.jmatprotec.2019.116276

M. Sadeghian, A. Ekrami, R. Jamshidi, Transient liquid phase bonding of 304 stainless steel using a Co-based interlayer. Sci. Technol. Weld. J. 22(8), 666–672 (2017)

M. MazarAtabaki, J. Noor Wati, J. Idris, transient liquid phase diffusion brazing of stainless steel 304. Weld. J. 92, 57–63 (2013)

Standard ASTM G59–97, Standard Test Method for Conducting Potentiodynamic Polarization Resistance Measurements. Annual Book of ASTM Standards (2009), pp. 237–239

T.B. Massalski (ed.), Binary Alloy Phase Diagrams (ACM, Metals Park, 1986)

E.E. Stansbury, R.A. Buchanan, Fundamentals of Electrochemical Corrosion (ASM Internationals, Materials Park, 2000)

J.C. Lippold, S.D. Kiser, J.N. DuPont, Welding Metallurgy and Weldability of Nickel-Base Alloys (Wiley, Singapore, 2009)

J.F. Shackelford, W. Alexander, Materials Science and Engineering Handbook, 3rd edn. (CRC Press, Boca Raton, 2001)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Solidification and solid state phenomena during TLP bonding of IN718 superalloy using Ni–Si–B ternary filler alloy. J. Alloys Compd. 563, 143–149 (2013)

ASM Handbook, Alloy Phase Diagrams, Vol. 3 (ASM International, USA, 1992)

A. Kazazi, A. Ekrami, Corrosion behavior of TLP bonded stainless steel 304 with Ni-based interlayer. J. Manuf. Process. 42, 131–138 (2019)

T. Tokunaga, K. Nishio, M. Hasebe, Thermodynamic study of phase equilibria in the Ni–Si–B system. J. Phase Equilib. 22, 291–299 (2001)

W. Jiang, J. Gong, S.T. Tu, Effect of brazing temperature on tensile strength and microstructure for a stainless steel plate-fin structure. Mater. Des. 32, 736–742 (2011)

W.D. MacDonald, T.W. Eagar, Isothermal solidification kinetics of diffusion brazing. Metall. Mater. Trans. A 29, 315–325 (1998)

K. Oikawa, R. Saito, K. Kobayashi, J. Yaokawa, K. Anzai, Phase equilibria in Ni-rich portion of Ni–Si system. Mater. Trans. 48(9), 2259–2262 (2007)

A. Ghasemi, M. Pouranvari, Microstructural evolution mechanism during brazing of Hastelloy X superalloy using Ni–Si–B filler metal. Sci. Technol. Weld. J. 23(5), 441–448 (2018)

E. Medvedovski, F.A. Chinski, J. Stewart, Wear- and corrosion-resistant boride-based coatings obtained through thermal diffusion CVD processing. Adv. Eng. Mater. 16(6), 713–728 (2014)

W. Batz, H.W. Mead, C.E. Birchenall, Diffusion of silicon in iron. J. Met. 4(10), 1070 (1952)

X. Zhang, X. Li, P. Wu, S. Chen, Sh. Zhang, N. Chen, X. Huai, First principles calculation of boron diffusion in fcc-Fe. Curr. Appl. Phys. 18, 1108–1112 (2018)

C.W. Sinclair, G.R. Purdy, J.E. Morral, Transient liquid-phase bonding in two-phase ternary systems. Metall. Mater. Trans. A 31(4), 1187–1192 (2000)

ASTM A 887, Standard Specification for Borated Stainless Steel Plate, Sheet, and Strip for Nuclear Application (ASTM International, 2004)

M. Pouranvari, A. Ekrami, A.H. Kokabi, Microstructure development during transient liquid phase bonding of GTD-111 nickel-based superalloy. J. Alloys Compd. 461(1), 641–647 (2008)

B. Shahabi Kargar, M.H. Moayed, A. Babakhani, A. Davoodi, Improving the corrosion behaviour of powder metallurgical 316L alloy by prepassivation in 20% nitric acid. Corros. Sci. 53(1), 135–146 (2011)

J.A. Verduzco, V.H. Verduzco, L. Dzib-Pérez, J. González-Sánchez, V.H. López, J. Solís, Corrosion resistance of bonding zone of AISI 316L–304 stainless steels joined with iron based glass ribbon interlayer: microstructural effects. Corros. Eng. Sci. Technol. 47(3), 233–240 (2012)

X. Zhou, Y. Dong, Ch. Liu, Y. Liu, L. Yu, J. Chen, H. Li, J. Yang, Transient liquid phase bonding of CLAM/CLAM steels with Ni-based amorphous foil as the interlayer. Mater. Des. 88, 1321–1325 (2015)

S. Borde`re, E. Feuillet, J.-L. Diot, R. De Langlade, J.-F. Silvain, Understanding of void formation in Cu/Sn–Sn/Cu system during transient liquid phase bonding process through diffusion modeling. Metall. Mater. Trans. B 49, 3343–3356 (2018)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Mirzaei, S., Binesh, B. Microstructure Evolution Mechanism and Corrosion Behavior of Transient Liquid Phase Bonded 304L Stainless Steel. Met. Mater. Int. 27, 3417–3431 (2021). https://doi.org/10.1007/s12540-020-00671-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00671-3