Abstract

To establish effective chemical transformations, catalytic systems with advantages such as high activity, recyclability, durability, and operability have attracted considerable attention. One of the strategies for the development of high-performance catalytic systems is the use of polymer hydrogels. In this focus review, an overview of our research using poly(N-isopropyl acrylamide)-based hydrogel particles and macroporous monoliths as molecular catalysts and loading matrices for palladium catalysts is summarized.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Benaglia M, Puglisi A, Cozzi F. Polymer-supported organic catalysts. Chem Rev. 2003;103:3401–29.

Ikegami S, Hamamoto H. Novel recycling system for organic synthesis via designer polymer-gel catalysts. Chem Rev. 2009;109:583–93.

Bergbreiter DE. Soluble polymers as tools in catalysis. ACS Macro Lett. 2014;3:260–5.

McPhee W, Tam KC, Pelton R. Poly(N-isopropylacrylamide) latices prepared with sodium dodecyl sulfate. J Colloid Interface Sci. 1993;156:24–30.

Debord JD, Lyon LA. Synthesis and characterization of pH-responsive copolymer microgels with tunable volume phase transition temperatures. Langmuir. 2003;19:7662–4.

Hoshino Y, Imamura K, Yue M, Inoue G, Miura Y. Reversible absorption of CO2 triggered by phase transition of amine-containing micro- and nanogel particles. J Am Chem Soc. 2012;134:18177–80.

Seto H, Morii T, Yoneda T, Murakami T, Hoshino Y, Miura Y. Preparation of palladium-loaded polymer nanoparticles with catalytic activity for hydrogenation and Suzuki coupling reactions. Chem Lett. 2013;42:301–3.

Yue M, Hoshino Y, Ohshiro Y, Imamura K, Miura Y. Temperature‐responsive microgel films as reversible carbon dioxide absorbents in wet environment. Angew Chem, Int Ed. 2014;53:2654–7.

Yue M, Hoshino Y, Miura Y. Design rationale of thermally responsive microgel particle films that reversibly absorb large amounts of CO2: Fine tuning the pK a of ammonium ions in the particles. Chem Sci. 2015;6:6112–23.

Seto H, Imai K, Hoshino Y, Miura Y. Polymer microgel particles as basic catalysts for Knoevenagel condensation in water. Polym J. 2016;48:897–904.

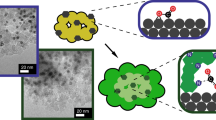

Matsumoto H, Akiyoshi T, Hoshino Y, Seto H, Miura Y. Size-tuned hydrogel network of palladium-confining polymer particles: a highly active and durable catalyst for Suzuki coupling reactions in water at ambient temperature. Polym J. 2018;50:1179–86.

Feil H, Bae YH, Feijen J, Kim SW. Mutual influence of pH and temperature on the swelling of ionizable and thermosensitive hydrogels. Macromolecules. 1992;25:5528–30.

Yue M, Imai K, Yamashita C, Miura Y, Hoshino Y. Effects of hydrophobic modifications and phase transitions of polyvinylamine hydrogel films on reversible CO2 capture behavior: comparison between copolymer films and blend films for temperature-responsive CO2 absorption. Macromol Chem Phys. 2017;218:1600570.

Yue M, Imai K, Miura Y, Hoshino Y. Design and preparation of thermo-responsive vinylamine-containing micro-gel particles for reversible absorption of carbon dioxide. Polym J. 2017;49:601–6.

Welsch N, Ballauff M, Lu Y. Microgels as nanoreactors: applications in catalysis. Adv Polym Sci. 2011;234:129–63.

Díaz DD, Kühbeck D, Koopmans RJ. Stimuli-responsive gels as reaction vessels and reusable catalysts. Chem Soc Rev. 2011;40:427–48.

Wong YM, Hoshino Y, Sudesh K, Miura Y, Numata K. Optimization of poly(N-isopropylacrylamide) as an artificial amidase. Biomacromolecules. 2015;16:411–21.

Nakamoto M, Nonaka T, Shea KJ, Miura Y, Hoshino Y. Design of synthetic polymer nanoparticles that facilitate resolubilization and refolding of aggregated positively charged lysozyme. J Am Chem Soc. 2016;138:4282–5.

Kureha T, Nagase Y, Suzuki D. High reusability of catalytically active gold nanoparticles immobilized in core–shell hydrogel microspheres. ACS Omega. 2018;3:6158–65.

Wang G, Kuroda K, Enoki T, Grosberg A, Masamune S, Oya T, et al. Gel catalysts that switch on and off. Proc Natl Acad Sci USA. 2000;97:98614.

Li JJ, Gribble GW. Palladium in heterocyclic chemistry: a guide for the synthetic chemist. Oxford: Pergamon; 2000.

Phan NT, Van Der Sluys M, Jones CW. On the nature of the active species in palladium catalyzed Mizoroki-Heck and Suzuki-Miyaura couplings—Homogeneous or heterogeneous catalysis: a critical review. Adv Synth Catal. 2006;348:609–79.

Narayanan R, El-Sayed MA. Catalysis with transition metal nanoparticles in colloidal solution: nanoparticle shape dependence and stability. J Phys Chem C. 2005;109:12663–76.

Iglesias M, Antic´o E, Salvad´o V. Recovery of palladium(II) and gold(III) from diluted liquors using the resin duolite GT-73. Anal Chim Acta. 1999;381:61–7.

Fänger C, Wack H, Ulbricht M. Macroporous poly(N-isopropylacrylamide) hydrogels with adjustable size “cutoff” for the efficient and reversible immobilization of biomacromolecules. Macromol Biosci. 2006;6:393–402.

Noël T, Buchwald SL. Cross‐coupling in flow. Chem Soc Rev. 2011;40:5010–29.

Seto H, Yoneda T, Morii T, Hoshino Y, Miura Y, Murakami T. Membrane reactor immobilized with palladium-loaded polymer nanogel for continuous-flow Suzuki coupling reaction. AIChE J. 2015;61:582–9.

Svec F. Porous polymer monoliths: amazingly wide variety of techniques enabling their preparation. J Chromatogr A. 2010;1217:902–24.

Hjerten S, Liao JL, Zhang R. High-performance liquid chromatography on continuous polymer beds. J Chromatogr. 1989;473:273–5.

Svec F, Fréchet JMJ. Continuous rods of macroporous polymer as high-performance liquid chromatography separation media. Anal Chem. 1992;64:820–2.

Wang QC, Svec F, Fréchet JMJ. Macroporous polymeric stationary-phase rod as continuous separation medium for reversed-phase chromatography. Anal Chem. 1993;65:2243–8.

Wang QC, Svec F, Fréchet JMJ. Reversed-phase chromatography of small molecules and peptides on a continuous rod of macroporous poly(styrene-co-divinylbenzene). J Chromatogr A. 1994;669:230–5.

Svec F, Fréchet JMJ. Kinetic control of pore formation in macroporous polymers. Formation of “molded” porous materials with high flow characteristics for separations or catalysis. Chem Mater. 1995;7:707–15.

Svec F, Fréchet JMJ. Temperature, a simple and efficient tool for the control of pore size distribution in macroporous polymers. Macromolecules. 1995;28:7580–2.

Wang QC, Svec F, Fréchet JMJ. Hydrophilization of porous polystyrene-based continuous rod column. Anal Chem. 1995;67:670–4.

Svec F, Fréchet JMJ. New designs of macroporous polymers and supports: from separation to biocatalysis. Science. 1996;273:205–11.

Viklund C, Svec F, Fréchet JMJ, Irgum K. Monolithic, “molded”, porous materials with high flow characteristics for separations, catalysis, or solid-phase chemistry: control of porous properties during polymerization. Chem Mater. 1996;8:744–50.

Peters EC, Petro M, Svec F, Fréchet JMJ. Molded rigid polymer monoliths as separation media for capillary electrochromatography. Anal Chem. 1997;69:3646–9.

Xie S, Svec F, Fréchet JMJ. Rigid porous polyacrylamide-based monolithic columns containing butyl methacrylate as a separation medium for the rapid hydrophobic interaction chromatography of proteins. J Chromatogr A. 1997;775:65–72.

Xie S, Svec F, Fréchet JMJ. Preparation of porous hydrophilic monoliths: effect of the polymerization conditions on the porous properties of poly(acrylamide‐co‐N,N′‐methylenebisacrylamide) monolithic rods. J Polym Sci Part A: Polym Chem. 1997;35:1013–21.

Peters EC, Petro M, Svec F, Fréchet JMJ. Molded rigid polymer monoliths as separation media for capillary electrochromatography. 1. Fine control of porous properties and surface chemistry. Anal Chem. 1998;70:2288–95.

Xie S, Svec F, Fréchet JMJ. Design of reactive porous polymer supports for high throughput bioreactors: Poly(2‐vinyl‐4,4‐dimethylazlactone‐co‐acrylamide‐co‐ethylene dimethacrylate) monoliths. Biotechnol Bioeng. 1999;62:30–5.

Jančo M, Sýkora D, Svec F, Fréchet JMJ. Rapid determination of molecular parameters of synthetic polymers by precipitation/redissolution high‐performance liquid chromatography using “molded” monolithic column. J Polym Sci Part A: Polym Chem. 2000;38:2767–78.

Yu C, Svec F, Fréchet JMJ. Towards stationary phases for chromatography on a microchip: Molded porous polymer monoliths prepared in capillaries by photoinitiated in situ polymerization as separation media for electrochromatography. Electrophoresis. 2000;21:120–7.

Rohr T, Yu C, Davey MH, Svec F, Fréchet JMJ. Porous polymer monoliths: Simple and efficient mixers prepared by direct polymerization in the channels of microfluidic chips. Electrophoresis. 2001;22:3959–67.

Yu C, Xu M, Svec F, Fréchet JMJ. Preparation of monolithic polymers with controlled porous properties for microfluidic chip applications using photoinitiated free‐radical polymerization. J Polym Sci Part A: Polym Chem. 2002;40:755–69.

Peterson DS, Rohr T, Svec F, Fréchet JMJ. Enzymatic microreactor-on-a-chip: protein mapping using trypsin immobilized on porous polymer monoliths molded in channels of microfluidic devices. Anal Chem. 2002;74:4081–8.

Kabra BG, Gehrke SH. Synthesis of fast response, temperature-sensitive poly(N-isopropylacrylamide) gel. Polym Commun. 1991;32:322–3.

Gotoh T, Nakatni Y, Sakohara S. Novel synthesis of thermosensitive porous hydrogels. J Appl Polym Sci. 1998;69:895–906.

Seto H, Matsumoto H, Shibuya M, Akiyoshi T, Hoshino Y, Miura Y. Poly(N‐isopropylacrylamide) gel‐based macroporous monolith for continuous‐flow recovery of palladium(II) ions. J Appl Polym Sci. 2017;134:44385.

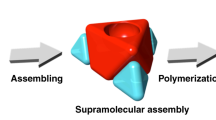

Matsumoto H, Seto H, Akiyoshi T, Shibuya M, Hoshino Y, Miura Y. Macroporous gel with a permeable reaction platform for catalytic flow synthesis. ACS Omega. 2017;2:8796–802.

Matsumoto H, Seto H, Akiyoshi T, Shibuya M, Hoshino Y, Miura Y. Macroporous monolith with polymer gel matrix as continuous-flow catalytic reactor. Chem Lett. 2017;46:1065–7.

Seto H, Shibuya M, Matsumoto H, Hoshino Y, Miura Y. Glycopolymer monoliths for affinity bioseparation of proteins in a continuous-flow system: glycomonoliths. J Mater Chem B. 2017;5:1148–54.

Miura Y, Seto H, Shibuya M, Hoshino Y. Biopolymer monolith for protein purification. Faraday Discuss 2019;219:154–67.

Acknowledgements

These works were supported by Grants-in-Aid for JSPS Fellows (25.5206, 18J20345), a Grant-in-Aid for Scientific Research on Innovative Areas (16H01036), and a Grant-in-Aid for Scientific Research (C) (19K05042). We deeply thank the collaborators and students cited herein.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Seto, H., Matsumoto, H. & Miura, Y. Preparation of palladium-loaded polymer hydrogel catalysts with high durability and recyclability. Polym J 52, 671–679 (2020). https://doi.org/10.1038/s41428-020-0323-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-020-0323-z