Abstract

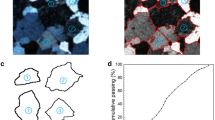

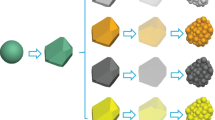

A novel 3D grain-based model (3D-GBM) based on Voronoi tessellation technology is proposed and implemented into a three-dimensional particle flow code (PFC3D) to investigate the micromechanical properties of salt rock at the grain scale. Parameter calibration is performed for numerical test configurations with various microparameters matched with the macroresponses observed in laboratory experiments (e.g., uniaxial compression test, triaxial compression test, and the Brazilian splitting test). Verifications comparing the simulated results and laboratory tests indicate that the 3D-GBM provides an alternative and promising approach for efficiently reproducing the micromechanical behavior of crystalline salt rocks.

Similar content being viewed by others

References

Abdelaziz A, Zhao Q, Grasselli G (2018) Grain based modelling of rocks using the combined finite-discrete element method. Comput Geotech 103:73–81

Anno (1993) Use of solution-mined caverns in salt for oil and gas storage and toxic waste disposal in Germany. Eng Geol 35(3):183–190

Azevedo NM, Candeias M, Gouveia F (2015) A rigid particle model for rock fracture following the Voronoi tessellation of the grain structure: formulation and validation. Rock Mech Rock Eng 48(2):535–557

Bahrani N, Kaiser PK (2016) Numerical investigation of the influence of specimen size on the unconfined strength of defected rocks. Comput Geotech 77:56–67

Bahrani N, Kaiser PK, Valley B (2014) Distinct element method simulation of an analogue for a highly interlocked, non-persistently jointed rockmass. Int J Rock Mech Min Sci 71:117–130

Bewick RP, Kaiser PK, Bawden WF (2014) DEM simulation of direct shear: 2. Grain boundary and mineral grain strength component influence on shear rupture. Rock Mech Rock Eng 47(5):1673–1692

Chan KS, Bodner SR, Munson DE (1998) Recovery and healing of damage in WIPP salt. Int J Damage Mech 7(2):143–166

Cho N, Martin CD, Sego DC (2007) A clumped particle model for rock. Int J Rock Mech Min Sci 44(7):997–1010

Courant RL (1943) Variational methods for the solution of problems of equilibrium and vibration. Bull Am Meteorol Soc 49:1–23

Cuevas CDL (1997) Pore structure characterization in rock salt. Eng Geol 47(1–2):17–30

Cundall PA, Strack ODL (1980) Discussion: a discrete numerical model for granular assemblies. Géotechnique 30(3):331–336

Damjanac B, Fairhurst C (2010) Evidence for a long-term strength threshold in crystalline rock. Rock Mech Rock Eng 43(5):513–531

Desbois G, Zavada P, Schleder Z, Urai JL (2010) Deformation and recrystallization mechanisms in actively extruding salt fountain: microstructural evidence for a switch in deformation mechanisms with increased availability of meteoric water and decreased grain size (Qum Kuh, central Iran). J Struct Geol 32(4):580–594

Diederichs MS (2003) Manuel rocha medal recipient rock fracture and collapse under low confinement conditions. Rock Mech Rock Eng 36(5):339–381

Ding XB, Zhang LY (2014) A new contact model to improve the simulated ratio of unconfined compressive strength to tensile strength in bonded particle models. Int J Rock Mech Min Sci 69(3):111–119

Edelbro C (2010) Different approaches for simulating brittle failure in two hard rock mass cases: a parametric study. Rock Mech Rock Eng 43(2):151–165

Fakhimi A, Villegas T (2007) Application of dimensional analysis in calibration of a discrete element model for rock deformation and fracture. Rock Mech Rock Eng 40(2):193–211

Fan JY, Jiang DY, Liu W, Wu F, Chen J, Daemen JJK (2019) Discontinuous fatigue of salt rock with low-stress intervals. Int J Rock Mech Min Sci 115(3):77–86

Fredrich JT, Evans B, Wong TF (1990) Effect of grain-size on brittle and semibrittle strength: implications for micromechanical modeling of failure in compression. J Geophys Res Solid Earth 95(B7):10907–10920

Gao FQ, Stead D (2014) The application of a modified Voronoi logic to brittle fracture modelling at the laboratory and field scale. Int J Rock Mech Min Sci 68(68):1–14

Gao FQ, Stead D, Elmo D (2016) Numerical simulation of microstructure of brittle rock using a grain-breakable distinct element grain-based model. Comput Geotech 78:203–217

Ghazvinian E, Diederichs MS, Quey R (2014) 3D random Voronoi grain-based models for simulation of brittle rock damage and fabric-guided micro-fracturing. J Rock Mech Geotech Eng 6(6):506–521

Groh U, Konietzky H, Walter K, Herbst M (2011) Damage simulation of brittle heterogeneous materials at the grain size level. Theor Appl Fract Mech 55(1):31–38

Hadiseh M, Rassoul A (2018) Mechanical behavior of salt rock under uniaxial compression and creep tests. Int J Rock Mech Min Sci 110:19–27

Hannes H, Tayfun B, Jeoung S, Yoon Arno Z, Günter Z (2015) A grain based modeling study of mineralogical factors affecting strength, elastic behavior and micro fracture development during compression tests in granites. Eng Fract Mech 147:261–275

Hrennikoff A (1949) Framework method and its technique for solving plane stress problems. Inst Assoc Bridge Struct Eng 9:217–248

Itasca (2011) UDEC (Universal Distinct Element Code), Version 4.1. Itasca, Minneapolis

Itasca (2018) Itasca Consulting Group Inc. PFC manual, version 5.0. Minneapolis, Minneapolis

Ivars DM, Pierce ME, Darcel C, Reyes-Montes J, Potyondy DO, Young RP, Cundall PA (2011) The synthetic rock mass approach for jointed rock mass modelling. Int J Rock Mech Min Sci 48(2):219–244

Kazerani T (2013) Effect of micromechanical parameters of microstructure on compressive and tensile failure process of rock. Int J Rock Mech Min Sci 64(6):44–55

Lan HX, Martin CD, Hu B (2010) Effect of heterogeneity of brittle rock on micromechanical extensile behavior during compression loading. J Geophys Res Solid Earth 115(B1):B01202

Li Y, Liu W, Yang C, Daemen JJK (2014) Experimental investigation of mechanical behavior of bedded rock salt containing inclined interlayer. Int J Rock Mech Min Sci 69(3):39–49

Li J, Konietzky H, Fruhwirt T (2017a) Voronoi-based DEM simulation approach for sandstone considering grain structure and pore size. Rock Mech Rock Eng 50(10):2749–2761

Li XF, Li HB, Zhao J (2017b) 3D polycrystalline discrete element method (3PDEM) for simulation of crack initiation and propagation in granular rock. Comput Geotech 90:96–112

Li XF, Li X, Li HB, Zhang QB, Zhao J (2018) Dynamic tensile behaviours of heterogeneous rocks: the grain scale fracturing characteristics on strength and fragmentation. Int J Impact Eng 118:98–118

Li JL, Tang Y, Shi XL, Xu WJ, Yang CH (2019a) Modeling the construction of energy storage salt caverns in bedded salt. Appl Energy 255:113866

Li XF, Li HB, Zhao J (2019b) The role of transgranular capability in grain-based modelling of crystalline rocks. Comput Geotech 110:161–183

Li H, Yang CH, Ma HL, Shi XL, Zhang HN, Dong ZK (2020) A 3D grain-based creep model (3D-GBCM) for simulating long-term mechanical characteristic of rock salt. J Petrol Sci Eng 185:106672 (In press)

Liang W, Yang C, Zhao Y, Dusseault MB, Liu J (2007) Experimental investigation of mechanical properties of bedded salt rock. Int J Rock Mech Min Sci 44(3):400–411

Liu XY, Ma LJ, Ma SN, Zhang XW, Gao L (2011) Comparative study of four failure criteria for intact bedded rock salt. Int J Rock Mech Min Sci 48(2):341–346

Liu N, Li M, Chen W (2017) Mechanical deterioration of rock salt at different confinement levels: a grain-based lattice scheme assessment. Comput Geotech 84:210–224

Liu G, Cai M, Huang M (2018) Mechanical properties of brittle rock governed by micro-geometric heterogeneity. Comput Geotech 104:358–372

Liu W, Zhang ZX, Chen J, Fan JY, Jiang DY, Daemen JJK (2019) Physical simulation of construction and control of two butted-well horizontal cavern energy storage using large molded rock salt specimens. Energy 185:682–694

Ma HL, Yang CH, Li YP, Shi XL, Liu JF, Wang TT (2015) Stability evaluation of the underground gas storage in rock salts based on new partitions of the surrounding rock. Environ Earth Sci 73(11):6911–6925

Maji AK, Wang JL (1992) Experimental-study of fracture processes in rock. Rock Mech Rock Eng 25(1):25–47

Martin CD, Chandler NA (1994) The progressive fracture of Lac Du Bonnet granite. Int J Rock Mech Min Sci Geomech Abstr 31(6):643–659

Müller C, Lerch C, Otparlik K, Konietzky (2012) Simulation of the mechanical deterioration of rock salt at grain scale. In: Paper presented at the mechanical behavior of salt VII—proceedings of the 7th conference on the mechanical behavior of Salt, March

Müller C, Fruhwirt T, Haase D, Schlegel R, Konietzky H (2018) Modeling deformation and damage of rock salt using the discrete element method. Int J Rock Mech Min Sci 103:230–241

Olsson WA (1974) Grain-size dependence of yield stress in marble. J Geophys Res 79(32):4859–4862

Park J, Park C, Song J, Park E, Song J (2017) Polygonal grain-based distinct element modeling for mechanical behavior of brittle rock. Int J Numer Anal Methods Geomech 41(6):880–898

Peng J, Wong LNY, Teh CI (2017a) Influence of grain size heterogeneity on strength and micro-cracking behavior of crystalline rocks. J Geophys Res Solid Earth 122(2):1054–1073

Peng J, Wong LNY, Teh CI (2017b) Effects of grain size-to-particle size ratio on micro-cracking behavior using a bonded-particle grain-based model. Int J Rock Mech Min Sci 100:207–217

Peng J, Wong LNY, Teh CI, Li Z (2017c) Modeling micro-cracking behavior of Bukit Timah granite using grain-based model. Rock Mech Rock Eng 15(1–2):1–20

Potyondy DO (2010) A grain-based model for rock: approaching the true microstructure. In: Paper presented at the proceedings of the rock mechanics in the Nordic Countries, Kongsberg, Norway, June 9–12

Potyondy DO, Cundall PA (2004) A bonded-particle model for rock. Int J Rock Mech Min Sci 41(8):1329–1364

Qiang D, Wang D (2002) Grid generation and optimization based on centroidal Voronoi tessellations. Appl Math Comput 133(2):591–607

Quey R, Dawson PR, Barbe F (2011) Large-scale 3D random polycrystals for the finite element method: generation, meshing and remeshing. Comput Methods Appl Mech 200(17–20):1729–1745

Sun MJ, Hu XL, Ge YF, Lu S (2013) Microparameter prediction for a triaxial compression PFC3D model of rock using full factorial designs and artificial neural networks. Geotech Geol Eng 31(4):1249–1259

Tawadrous AS, Degagné D, Pierce M, Ivars DM (2010) Prediction of uniaxial compression PFC3D model micro-properties using artificial neural networks. Int J Numer Anal Methods Geomech 33(18):1953–1962

Wang G (2004) A new constitutive creep-damage model for salt rock and its characteristics. Int J Rock Mech Min 41(3):61–67

Wang X, Cai M (2018) Modeling of brittle rock failure considering inter- and intra-grain contact failures. Comput Geotech 101:224–244

Wang YN, Tonon F (2009) Modeling Lac du Bonnet granite using a discrete element model. Int J Rock Mech Min Sci 46(7):1124–1135

Wang TT, Yang CH, Li JJ, Li JL, Shi XL, Ma HL (2016) Failure analysis of overhanging blocks in the walls of a gas storage salt cavern: a case study. Rock Mech Rock Eng 50(1):1–13

Wang TT et al (2018) Salt cavern gas storage in an ultra-deep formation in Hubei, China. Int J Rock Mech Min Sci 102(2):57–70

Wong TF, Baud P (2012) The brittle–ductile transition in porous rock: a review. J Struct Geol 44(Complete):25–53

Wong RHC, Chau KT, Wang P (1996) Microcracking and grain size effect in Yuen Long marbles. Int J Rock Mech Min Sci Geomech Abstr 33(5):479–485

Xu X, Wu S, Gao Y, Xu M (2016) Effects of micro-structure and micro-parameters on Brazilian tensile strength using flat-joint model. Rock Mech Rock Eng 49(9):3575–3595

Yang CH, Daemen JJK, Yin JH (1999) Experimental investigation of creep behavior of salt rock. Int J Rock Mech Min Sci 36(2):233–242

Yang BD, Jiao Y, Lei ST (2006) A study on the effects of microparameters on macroproperties for specimens created by bonded particles. Eng Comput 23(5–6):607–631

Yin H, Yang C, Ma H, Shi X, Chen X, Zhang N, Ge X, Liu W (2019) Study on damage and repair mechanical characteristics of rock salt under uniaxial compression. Rock Mech Rock Eng 52(3):659–671

Yoon J (2007) Application of experimental design and optimization to PFC model calibration in uniaxial compression simulation. Int J Rock Mech Min Sci 44(6):871–889

Yoon JS, Zang A, Stephansson O (2012) Simulating fracture and friction of Aue granite under confined asymmetric compressive test using clumped particle model. Int J Rock Mech Min Sci 49(1):68–83

Závada P, Desbois G, Schwedt A, Lexa O, Urai JL (2012) Extreme ductile deformation of fine-grained salt by coupled solution-precipitation creep and microcracking: microstructural evidence from perennial Zechstein sequence (Neuhof salt mine, Germany). J Struct Geol 37(4):89–104

Zhang XP, Wong LNY (2014) Choosing a proper loading rate for bonded-particle model of intact rock. Int J Fract 189(2):163–179

Zhang N, Shi X, Zhang Y, Shan P (2020) Tightness analysis of underground natural gas and oil storage caverns with limit pillar widths in bedded rock salt. IEEE Access 8:12130 (In press)

Zhao G (2010) Development of micro–macro continuum–discontinuum coupled numerical method, Ph.D thesis. EPFL, Switzerland

Zhou XP, Zhang YX, Ha QL, Zhu KS (2008) Micromechanical modelling of the complete stress–strain relationship for crack weakened rock subjected to compressive loading. Rock Mech Rock Eng 41(5):747–769

Acknowledgements

The authors wish to acknowledge the National Natural Science Foundation of China (Grant nos. 51874274, 51774266) and National Key Research and Development Program of China (Grant nos. 2018YFC0808401, 2018YFC0808403). The authors are sincerely grateful to professor Chunhe Yang, Wuhan Institute of Rock and Soil Mechanics, for his useful framework and structure guidance and Jie Yang, Yue Han, Chongqing University, for their thoughtful proofreading of this paper.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Li, H., Ma, H., Shi, X. et al. A 3D Grain-Based Model for Simulating the Micromechanical Behavior of Salt Rock. Rock Mech Rock Eng 53, 2819–2837 (2020). https://doi.org/10.1007/s00603-020-02085-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00603-020-02085-4