Abstract

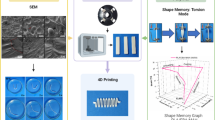

Ethylene-vinyl acetate–glycidyl methacrylate random terpolymer (EVM–GMA, VA = 60 wt%, GMA = 2.9%) was used as a polymeric plasticizer replacing the traditional dioctyl phthalate (DOP) to prepare a polyvinyl chloride (PVC) masterbatch. Polylactic acid (PLA) was applied to blend with the PVC masterbatch in melt to examine the epoxy ring-opening reactions between epoxy groups in EVM–GMA and end carboxyl groups in PLA in order to construct a special phase structure in PVC/PLA improving the mechanical properties and 3D printing performance. The formation and evolution of phase structures were revealed by aids of the unique rheological responses of multi-component composite system. The results showed that with the increase in EVM–GMA content, the phase morphology of PVC/PLA was refined from co-continuous phase structure to denser one and then evolved to sea-island structure. It was also found that the addition of EVM–GMA inhibited the crystallization of PLA and the cold crystallization as well. When PVC/EVM–GMA/PLA was incorporated in weight ratio of 45/5/50, the denser co-continuous phase structure with smaller domain imparted the composite a highest zero shear viscosity and viscous flow activation energy. This unique structure existed stably when the shear rate was less than 230 s−1 or below 180 °C. Consequently, it endowed composite the highest impact strengths and smoothest appearance of 3D printed specimens. Therefore, moderate EVM–GMA is not only a reliable alternative plasticizer for PVC, but also an ideal modifier for the compatibility of PVC/PLA blends which presented an excellent performance in 3D printing.

Similar content being viewed by others

References

Araújo EM, Hage E, Carvalho AJF (2004) Thermal properties of nylon6/ABS polymer blends: compatibilizer effect. J Mater Sci 39(4):1173–1178. https://doi.org/10.1023/B:JMSC.0000013872.86575.36

Sarasua JR, Arraiza AL, Balerdi P, Maiza I (2005) Crystallization and thermal behaviour of optically pure polylactides and their blends. J Mater Sci 40(8):1855–1862. https://doi.org/10.1007/s10853-005-1204-8

Li TY, Wang N, Fang QH (2010) Incorporation of modified soy protein isolate as filier in BR/SBR blends. J Mater Sci 45(7):1904–1911. https://doi.org/10.1007/s10853-009-4176-2

Bama GK, Devi PI, Ramachandran K (2009) Structural and thermal properties of PVDF/PVA blends. J Mater Sci 44(5):1302–1307. https://doi.org/10.1007/s10853-009-3271-8

Haque MU, Pracella M (2010) Reactive compatibilization of composites of ethylene–vinyl acetate copolymers with cellulose fibres. Compos Part A Appl Sci Manuf 41(10):1545–1550

Lyu Y, Pang JG, Gao ZJ, Zhang QL, Shi XY (2019) Characterization of the compatibility of PVC/PLA blends by aid of rheological responses. Polymer 176:20–29

Li XL, Xiao Y, Wang B, Xi HL, Ting X (2011) MMT and short time soaking in hexane to suppress DOP migrating from flexible PVC. Adv Mater Res 328–330:4

Jian YH, Liu DP, Ding YL, Li XH, Wang CL (2005) Release of dioctyl phthalate (DOP) from polyvinyl chloride (PVC) in apple packaging. Prog Nat Sci 15(1):145–148

Papaspyrides CD, Tingas SG (2015) Effect of thermal annealing on plasticizer migration in poly(vinyl chloride)/dioctyl phthalate system. J Appl Polym Sci 79(10):1780–1786

Stringer R, Labunska I, Santillo D, Paul J, John S, Angela S (2000) Concentrations of phthalate esters and identification of other additives in PVC children’s toys. Environ Sci Pollut Res 7(1):27–36

Tarvainen M, Sutinen R, Somppi M, Petteri P, Antti P (2001) Predicting plasticization efficiency from three-dimensional molecular structure of a polymer plasticizer. Pharm Res 18(12):1760

Lizymol PP, Thomas S, Jayabalan M (1997) Effect of dehydrochlorination of PVC on miscibility and phase separation of binary and ternary blends of poly(vinyl chloride), poly(ethylene-co-vinyl acetate) and poly(styrene-co-acrylonitrile). Polym Int 44(1):23–29

Lizymol PP, Thomas S (2010) Miscibility studies of polymer blends by viscometry methods. J Appl Polym Sci 51(4):635–641

Lizymol PP, Thomas S (1993) Thermal behaviour of polymer blends: a comparison of the thermal properties of miscible and immiscible systems. Polym Degrad Stab 41(1):59–64

Nomai J, Jarukumjorn K (2014) Effect of maleic anhydride grafted poly(lactic acid) on properties of sawdust/poly(lactic acid) composites toughened with poly(butylene adipate-co-terephthalate). Adv Mater Res 970:74–78

Zhang YC, Zhu ZF, Wu HY, Qiu YP (2010) Optimization fabrication of plasma treated nano-titanium dioxide particles/PP/PLA composites filaments using melt spinning. Mater Sci Forum 658:467–470

Haque MU, Puglia D, Fortunati E, Pracella M (2017) Effect of reactive functionalization on properties and degradability of poly(lactic acid)/poly(vinyl acetate) nanocomposites with cellulose nanocrystals. React Funct Polym 110:1–9

Chen XL, Yu J, Guo SY, Lu SJ, Luo Z, He M (2009) Surface modification of magnesium hydroxide and its application in flame retardant polypropylene composites. J Mater Sci 44(5):1324–1332. https://doi.org/10.1007/s10853-009-3273-6

Huang ZY, Lu SR, Yang ZY (2011) Studies on the properties of epoxy resins modified with novel liquid crystalline polyurethane. Adv Mater Res 150–151(9):727–731

Kumar M, Mohanty S, Nayak SK, Parvaiz MR (2010) Effect of glycidyl methacrylate (GMA) on the thermal, mechanical and morphological property of biodegradable PLA/PBAT blend and its nanocomposites. Biores Technol 101(21):8406–8415

Bredikhina ZA, Novikova VG, Zakharychev DV, Bredikhin AA (2004) Solid state properties and effective for guaifenesin, 3-(2-methoxyphenoxy)-1, 2-propanediol. Powder Diffr 19(2):127–132

Hardis R, Jessop JLP, Peters FE, Kessler MR (2013) Cure kinetics characterization and monitoring of an epoxy resin using DSC, Raman spectroscopy, and DEA. Compos Part A Appl Sci Manuf 49(49):100–108

Vo Hong N, Trujillo E, Puttemans F, Jansens KJA, Goderis B, Puyvelde PV, Verpoest I, Vuure AWV (2016) Developing rigid gliadin based biocomposites with high mechanical performance. Compos Part A Appl Sci Manuf 85:76–83

Zheng J, Dang H, Feng XY, Chien PH, Hu YY (2017) Li-ion transport in a representative ceramic–polymer–plasticizer composite electrolyte: Li7La3Zr2O12–polyethylene oxide–tetraethylene glycol dimethyl ether. J Mater Chem A 5(35):18457

Jojibabu P, Jagannatham M, Haridoss P, Ram GDJ, Deshpande AP, Bakshi SR (2016) Effect of different carbon nano-fillers on rheological properties and lap shear strength of epoxy adhesive joints. Compos A 82:53–64

Han CD (1973) Influence of the die entry angle on the entrance pressure drop, recoverable elastic energy, and onset of flow instability in polymer melt flow. J Appl Polym Sci 17(5):1403–1413

Crossley RJ, Schubel PJ, De Focatiis DSA (2013) Time-temperature equivalence in the tack and dynamic stiffness of polymer prepreg and its application to automated composites manufacturing. Compos Part A Appl Sci Manuf 52(5):126–133

Cheng C, Zhang XL, Meng YB, Zhang ZH, Chen JD, Zhang QQ (2017) Multiresponsive and biocompatible self-healing hydrogel: its facile synthesis in water, characterization and properties. Soft Matter 13(16):3003–3012

Marciel A, Srivastava S, Tirrell MV (2018) Structure and rheology of polyelectrolyte complex coacervates. Soft Matter 14(13):2454–2464

Chen HZ, Cheng X, Li JJ, Zhang Y (2018) Dynamic rheological characteristics of polycarbosilance melt in linear viscoelastic region. Silicon 4:1–7

Gilbert L, Picard C, Savary G, Grisel M (2013) Rheological and textural characterization of cosmetic emulsions containing natural and synthetic polymers: relationships between both data. Colloid Surface A 421:150–163

Rohindra DR, Lata RA, Coll RK (2012) A simple experiment to determine the activation energy of the viscous flow of polymer solutions using a glass capillary viscometer. Eur J Phys 33(5):1457–1464

Pattanayek SK, Ghosh AK (2018) Dynamic shear rheology of colloidal suspensions of surface-modified silica nanoparticles in PEG. J Nanopart Res 20(3):53

Acknowledgements

The authors would like to acknowledge the support of Natural Science Foundation of Shandong Province (ZR2018MEM025), without which the work presented in this article, would not have been possible.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lyu, Y., Yin, H., Chen, Y. et al. Structure and evolution of multiphase composites for 3D printing. J Mater Sci 55, 6861–6874 (2020). https://doi.org/10.1007/s10853-020-04505-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10853-020-04505-w