Abstract

Formability of Al/Mg or Al/Mg/Al laminates is essential to their further manufacture and application. However, there are few reports on their formability compared with the investigation on their microstructures and mechanical properties. In this paper, bulging deformation of Al/Mg/Al laminate was conducted at 170, 200, and 230 °C. The results show that both temperature and strain state affect the formability of laminate, and the peak dome height of 36.5 mm was obtained at 230 °C under equibiaxial tensile strain. Further texture analysis indicates that Mg layer exhibits basal texture with most grains elongated along the rolling direction, and continuous dynamic recrystallization occurs during the bulging process. Necking or fracture positions of bulging parts appear at outer rings, not at the apex with the highest deformation degree. For the same strain state and direction, the range of necking or cracking is extended and wall thickness along different directions is uniformized when temperature rises. Interfacial structure observation shows that cracking occurs in various positions in bulging, including in Al3Mg2, at Al/Al3Mg2, Mg17Al12/Al3Mg2, and Mg17Al12/Mg interfaces, which is almost impervious to temperature.

Similar content being viewed by others

References

F.K. Chen and K.H. Chiu, Stamping Formability of Pure Titanium Sheets, J. Mater. Process. Technol., 2005, 170(1-2), p 181–186

Y. Tadano, Formability of Magnesium Sheet with Rolling Texture, Int. J. Mech. Sci., 2016, 108-109, p 72–82

T.F. Zhang, S.K. Xie, J.H. Huang, and Z.H. Guo, Simulation Experiment on Friction Coefficients during Warm Deep Drawing of Magnesium Alloy Sheet, Appl. Mech. Mater., 2010, 33, p 38–42

Q. Zhang and Z.R. Wang, Shape Improvement of a Dieless Hydro-Bulged Sphere Made of Hexagonal and Pentagonal Shaped Panels, J. Mater. Process. Technol., 2015, 220, p 87–95

C. Li, K.F. Zhang, S.S. Jiang, and Z.P. Zhao, Pulse Current Auxiliary Bulging and Deformation Mechanism of AZ31 Magnesium Alloy, Mater. Des., 2012, 34, p 170–178

X.Y. Wang, J.C. Xia, G.A. Hu, Z.J. Wang, and Z.R. Wang, Sheet Bulging Experiment with a Viscous Pressure-Carrying Medium, J. Mater. Process. Technol., 2004, 151(1-3), p 340–344

D. Griffiths, Explaining Texture Weakening and Improved Formability in Magnesium Rare Earth Alloys, Mater. Sci. Technol., 2015, 31(1), p 10–24

Q. Wang, B. Jiang, A. Tang, C. He, D. Zhang, J. Song, T. Yang, G. Huang, and F. Pan, Formation of the Elliptical Texture and Its Effect on the Mechanical Properties and Stretch Formability of Dilute Mg-Sn-Y Sheet by Zn Addition, Mater. Sci. Eng. A, 2019, 746, p 259–275

O.M. Badr, B. Rolfe, and M. Weiss, Effect of the Forming Method on Part Shape Quality in Cold Roll Forming High Strength Ti-6Al-4V Sheet, J. Manuf. Process., 2018, 32, p 513–521

W. Cheng, L. Wang, H. Zhang, and X. Cao, Enhanced Stretch Formability of AZ31 Magnesium Alloy Thin Sheet by Pre-crossed Twinning Lamellas Induced Static Recrystallizations, J. Mater. Process. Technol., 2018, 254, p 302–309

Z. Wang, R. Gu, S. Chen, W. Wang, and X. Wei, Effect of Upper-Die Temperature on the Formability of AZ31B Magnesium Alloy Sheet in Stamping, J. Mater. Process. Technol., 2018, 257, p 180–190

J.R. Xu, H.P. Yu, J. Cui, and C.F. Li, Formability of AZ31 Magnesium Alloy Sheets during Magnetic Pulse Bulging, Mater. Sci. Eng. A, 2013, 569, p 150–158

H. Yu, C. Lu, A.K. Tieu, H. Li, A. Godbole, and C. Kong, Annealing Effect on Microstructure and Mechanical Properties of Al/Ti/Al Laminate Sheets, Mater. Sci. Eng. A, 2016, 660, p 195–204

P.D. Motevalli and B. Eghbali, Microstructure and Mechanical Properties of Tri-Metal Al/Ti/Mg Laminated Composite Processed by Accumulative Roll Bonding, Mater. Sci. Eng. A, 2015, 628, p 135–142

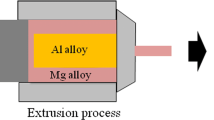

J. Tang, L. Chen, G. Zhao, C. Zhang, and J. Yu, Study on Al/Mg/Al Sheet Fabricated by Combination of Porthole Die Co-extrusion and Subsequent Hot Rolling, J. Alloys Compd., 2019, 784, p 727–738

D.M. Fronczek, R. Chulist, L. Litynska-Dobrzynska, S. Kac, N. Schell, Z. Kania, Z. Szulc, and J. Wojewoda-Budka, Microstructure and Kinetics of Intermetallic Phase Growth of Three-Layered A1050/AZ31/A1050 Clads Prepared by Explosive Welding Combined with Subsequent Annealing, Mater. Des., 2017, 130, p 120–130

H. Nie, W. Liang, L. Zheng, X. Ren, and H. Fan, The Microstructure, Texture and Mechanical Properties of the Rolled Al/Mg/Al Clad Sheets, J. Mater. Eng. Perform., 2016, 25(11), p 4695–4705

C. Li, C. Chi, P. Lin, H. Zhang, and W. Liang, Deformation Behavior and Interface Microstructure Evolution of Al/Mg/Al Multilayer Composite Sheets during Deep Drawing, Mater. Des., 2015, 77, p 15–24

H. Nie, W. Liang, H. Chen, F. Wang, T. Li, C. Chi, and X. Li, A Coupled EBSD/TEM Study on the Interfacial Structure of Al/Mg/Al Laminates, J. Alloys Compd., 2019, 781, p 696–701

L. Mao, C. Liu, Y. Gao, X. Han, S. Jiang, and Z. Chen, Microstructure and Mechanical Anisotropy of the Hot Rolled Mg-8.1Al-0.7Zn-0.15Ag Alloy, Mater. Sci. Eng. A, 2017, 701, p 7–15

H. Xiao, B. Tang, C. Liu, Y. Gao, S. Yu, and S. Jiang, Dynamic Precipitation in a Mg-Gd-Y-Zr Alloy during Hot Compression, Mater. Sci. Eng. A, 2015, 645, p 241–247

H. Somekawa, A. Kinoshita, and A. Kato, Great Room Temperature Stretch Formability of Fine-Grained Mg-Mn Alloy, Mater. Sci. Eng. A, 2017, 697, p 217–223

C.Z. Luo, W. Liang, Z.Q. Chen, J.J. Zhang, C.Z. Chi and F.Q. Yang, Effect of High Temperature Annealing and Subsequent Hot Rolling on Microstructural Evolution at the Bond-Interface of Al/Mg/Al Alloy Laminated Composites. Mater. Chara., 2013, 84, p 34–40

J.C. Tan and M.J. Tan, Dynamic Continuous Recrystallization Characteristics in Two Stage Deformation of Mg-3Al-1Zn Alloy Sheet, Mater. Sci. Eng. A, 2003, 339(1), p 124–132

A. Galiyev, R. Kaibyshev, and G. Gotstein, Correlation of Plastic Deformation and Dynamic Recrystallization in Magnesium Alloy ZK60, Acta Mater., 2001, 49, p 1199–1207

F. Shen, Z. Zhou, W. Li, Z. Sun, J. Tian, C. Xie, J. Guo, Z. Liao, D. Yi, J. Zhang, H. Wang, and B. Jiang, Micro-mechanism of Texture Evolution during Isochronal Annealing of As-Annealed Hot Rolled Al-Cu-Mg Sheet, Mater. Des., 2019, 165, p 107575

S. Wronski, B. Ghilianu, T. Chauveau, and B. Bacroix, Analysis of Textures Heterogeneity in Cold and Warm Asymmetrically Rolled Aluminium, Mater. Charact., 2011, 62(1), p 22–34

J. Zhang, M. Ma, F. Shen, D. Yi, and B. Wang, Influence of Deformation and Annealing on Electrical Conductivity, Mechanical Properties and Texture of Al-Mg-Si Alloy Cables, Mater. Sci. Eng. A, 2018, 710, p 27–37

X. Wang, M. Guo, J. Luo, C. Xie, Y. Wang, J. Zhang, and L. Zhuang, Effect of Intermediate Annealing Time on Microstructure, Texture and Mechanical Properties of Al-Mg-Si-Cu Alloy, Mater. Charact., 2018, 142, p 309–320

K. Hamad, H.W. Yang, and Y.G. Ko, Interpretation of Annealing Texture Changes of Severely Deformed Al-Mg-Si Alloy, J. Alloys Compd., 2016, 687, p 300–305

Acknowledgments

This study was supported by Shanxi provincial Youth Fund under Grant No. 201801D221101; Scientific and Technological Innovation Programs of Higher Education Institutions in Shanxi under Grant No. RD1900000636; the National Natural Science Foundation of China under Grant Nos. U1810208, 51274149, 51474152 and U1710254; Shanxi province science and technology major projects under Grant No. 20181101008.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Nie, H., Liang, W., Kang, X. et al. Bulging Ability and Microstructure Evolutions of Al/Mg/Al Laminate. J. of Materi Eng and Perform 29, 1782–1791 (2020). https://doi.org/10.1007/s11665-020-04717-w

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-020-04717-w