Abstract

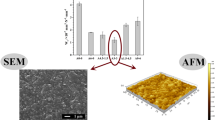

Basalt fibre (BF)/acrylonitrile–butadiene rubber (NBR) composites with various BF contents and orientations were prepared, and the curing, physical and mechanical properties and wear performance under block-on-ring abrasion conditions were evaluated. The results showed that the curing time was not obviously affected by the BFs. The addition of BFs increased the hardness but had negative influence on the tensile/tear strength of the NBR composites, especially when the BFs were oriented perpendicular to the tensile/tear direction with a high content, which should be due to the weak connection between the BFs and the rubber matrix. The coefficient of friction (COF) of the composites decreased significantly when BFs were added, whereas the content (3–30 phr) and the orientation of the fibres did not mainly affect the COF. Both parallel- and perpendicular-oriented BFs were effective at improving the wear resistance of the composites, and the former showed a better effect. With the BF content increase, the wear rate initially decreased and then remained basically stable. The COF and wear rate of the composites decreased by 27% and 35% when 12 phr BFs were added in a parallel direction. The excessive BFs, especially the perpendicularly-oriented BFs, led to fracture of the worn surface due to the abrasive grain wear caused by the crushed fibres.

Similar content being viewed by others

References

Razavizadeh M, Jamshidi M (2017) Effects of methylene diphenyl diisocyanate on the physical, mechanical, and vulcanization properties of nitrile rubber. J Appl Polym Sci 134:45200

Dong CL, Yuan CQ, Bai XQ, Yan XP, Peng Z (2015) Tribological properties of aged nitrile butadiene rubber under dry sliding conditions. Wear 322–323:226–237

Li YQ, Wang QH, Wang TM, Pan GQ (2012) Preparation and tribological properties of graphene oxide/nitrile rubber nanocomposites. J Mater Sci 47:730–738

Lubwama M, McDonnell KA, Kirabira JB, Sebbit A, Sayers K, Dowling D, Corcoran B (2012) Characteristics and tribological performance of DLC and Si-DLC films deposited on nitrile rubber. Surf Coat Technol 206:4585–4593

Lubwama M, Corcoran B, Sayers K (2015) DLC films deposited on rubber substrates: a review. Surf Eng 31:1–10

Martinez-Martinez D, De Hosson JTM (2014) On the deposition and properties of DLC protective coatings on elastomers: a critical review. Surf Coat Technol 258:677–690

Wang QL, Yang FY, Yang Q, Chen JH, Guan HY (2010) Comparison on tribological properties of NBR composites filled with nano-Fe3O4 and nano-SrO·6Fe2O3. Tribology 30:128–134

Li YL, Wang SJ, Wang Q, Xing M (2016) Molecular dynamics simulations of tribology properties of NBR (Nitrile-Butadiene Rubber)/carbon nanotube composites. Compos B 97:62–67

Li XY, Qin HT, Chen X, Cheng XJ, Mei QL (2016) Influence of coumarone resin content on performance of nitrile rubber-based friction materials. J Wuhan Univ Technol 38:22–26

Wang LL, Zhang LQ, Tian M (2012) Mechanical and tribological properties of acrylonitrile–butadiene rubber filled with graphite and carbon black. Mater Des 39:450–457

Liang YR, Yang HX, Tan YJ, Zhang T, Wang LY, Hu G (2016) Mechanical and tribological properties of nitrile rubber filled with modified molybdenum disulphide. Plast Rubber Compos 45:247–252

Shadrinov NV, Nartakhova SI (2017) Structure and properties of nitrile-butadiene rubber filled with carbon and basalt fibers. Inorg Mater Appl Res 8:140–144

Li YZ, Li Z, Wan JJ, Yan ZQ, Sun JT, Zhao SG (2019) Mechanical and tribological performance of chopped basalt fiber/acrylonitrile-butadiene rubber composites. Polym Compos 40:630–637

Wang XX, Zhang JC, Zhang H, Qin L (2015) Tensile and friction properties of carbon fiber /nitrile rubber composites: influence of carbon fiber content and orientation. Polym Mater Sci Eng 31:92–101

Huang XW, Wang TM, Tian N, Wang K, Xue QJ (2006) Tribological properties of acrylonitrile-butadiene rubber reinforced with Kevlar aramid fiber. China Synth Rubber Ind 29:451–453

Fiore V, Scalici T, Di Bella G, Valenza A (2015) A review on basalt fibre and its composites. Compos B 74:74–94

Medjahed A, Derradji M, Zegaoui A, Wu R, Li B (2019) Mechanical and gamma rays shielding properties of a novel fiber-metal laminate based on a basalt/phthalonitrile composite and an Al-Li alloy. Compos Struct 210:421–429

Öztürk B, Arslan F, Öztürk S (2007) Hot wear properties of ceramic and basalt fiber reinforced hybrid friction materials. Tribol Int 40:37–48

Kumar AAJ, Srinivasan V (2018) Wear behavior of chitosan-filled polylactic acid/basalt fiber hybrid composites. Adv Polym Technol 37:898–905

Wang JZ, Chen BB, Liu N, Han GF, Yan FY (2014) Combined effects of fiber/matrix interface and water absorption on the tribological behaviors of water-lubricated polytetrafluoroethylene-based composites reinforced with carbon and basalt fibers. Compos A 59:85–92

Li Z, Xiao TL, Zhao SG (2016) Effects of surface treatments on mechanical properties of continuous basalt fibre cords and their adhesion with rubber matrix. Fiber Polym 17:910–916

Li Z, Xiao TL, Pan QY, Cheng JM, Zhao SG (2016) Corrosion behaviour and mechanism of basalt fibres in acidic and alkaline environments. Corros Sci 110:15–22

Duan CJ, Yuan DM, Yang ZH, Li S, Tao LM, Wang QH, Wang TM (2018) High wear-resistant performance of thermosetting polyimide reinforced by graphitic carbon nitride (g-C3N4) under high temperature. Compos A 113:200–208

Acknowledgements

The authors acknowledge the financial support from the National Natural Science Foundation of China (Grant Number 51603110).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Li, Z., Li, Y., Cheng, J. et al. Effects of fibre content and orientation on wear properties of basalt fibre/acrylonitrile–butadiene rubber composites. Iran Polym J 29, 361–367 (2020). https://doi.org/10.1007/s13726-020-00802-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13726-020-00802-y