Abstract

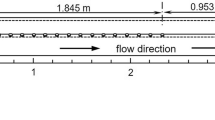

Velocity and concentration profiles in a pipe flow was measured downstream of injection of a tracer gas at the pipe centerline. The pipe had diameter D = 0.2 m and two Reynolds numbers, Re = 50000 and Re = 100000, were used. The profiles were measured at positions 5D and 10D downstream of the injection point. Three different industrial relevant geometrical configurations were used upstream of the injection point: a 10D straight pipe, two 10D pipes connected with a 90° bend or a straight 10D pipe with a mixer plate mounted 2D upstream the injection point. In all cases, air entered the pipe from the surroundings through a sharp-edged inlet. This represents many practical flow applications and is also a well-defined inlet condition that generates turbulence in the vena contracta in the inlet. The measurements were compared to predictions from three different computational models: two with Reynolds Averaged Navier-Stokes (RANS) and one with high-resolution Detached Eddy Simulation (DES). For RANS, the k-ω SST model had difficulty in predicting the turbulence created by the vena contracta. The k-ε model performed better, but gave completely wrong results for the inlet with a pipe bend. The DES was successful for all cases with only minor deviations from measurements.

Similar content being viewed by others

References

Reynolds O (1883) Proc R Soc London 35(224-226):84

Taylor GI (1922) Proc London Math Soc 2(1):196

Dimotakis PE (2005) Annu Rev Fluid Mech 37:329

Paul EL, Atiemo-Obeng VA, Kresta SM (2004) Handbook of industrial mixing: science and practice. Wiley

Jordan D (1961) Q J Mech Appl Math 14(2):203

Lee J, Brodkey RS (1964) AIChE J 10(2):187

Filmer RW, Yevjevich V (1967). In: Proceedings of 12th congress of the international association for hydraulic research. Colorado State University, pp 115–120

Evans G (1967) J Basic Eng 89(3):624

Clayton CG, Ball A, Spackman R (1968) Dispersion and mixing during turbulent flow of water in a circular pipe. Tech. rep., United Kingdom Atomic Energy Authority, Wantage (England). Research Group

Ger A, Holley E (1976) Journal of the Hydraulics Division p

Guiraud P, Bertrand J, Costes J (1991) Chem Eng Sci 46(5-6):1289

Laufer J (195) NASA reports REPORT 11744

Eggels J, Unger F, Weiss M, Westerweel J, Adrian R, Friedrich R, Nieuwstadt F (1994) J Fluid Mech 268:175

ISO5167-2:2003(E) (2003) Measurement of fluid flow by means of pressure differential devices inserted in circular-cross section conduits running full. International Organization for Standardization

Smith BC (2011) Fundamentals of Fourier transform infrared spectroscopy. CRC Press

Westlye FR (2012) Master Thesis Technical University of Denmark. Emission measurement and exhaust aftertreatment of an ammonia fueled si-engine

Jones WP, Launder BE (1972) Int J Heat Mass Transf 15(2):301. https://doi.org/10.1016/0017-9310(72)90076-2

Launder BE, Sharma BI (1974) Lett Heat Mass Transfer 1(2):131. https://doi.org/10.1016/0094-4548(74)90150-7

Menter F (1994) AIAA J 32(8):1598

Wilcox D (2008) AIAA J 46(11):2823

CD-adapco (2017) STAR-CCM+ Manual. CD-adapco, 11th edn

Weltens H, Bressler H, Terres F, Neumaier H, Rammoser D (1993) Optimisation of catalytic converter gas flow distribution by cfd prediction. Tech. rep., SAE Technical Paper

Johansson Å, Wallin U, Karlsson M, Isaksson A, Bush P (2008) Investigation on uniformity indices used for diesel exhaust aftertreatment systems. Tech. rep., SAE Technical Paper

Acknowledgements

This project was funded by the European Union Horizon 2020 - Hercules-2 - research and innovation program under Grant Agreement No. 634135.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interests

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gotfredsen, E., Kunoy, J.D., Mayer, S. et al. Experimental validation of RANS and DES modelling of pipe flow mixing. Heat Mass Transfer 56, 2211–2224 (2020). https://doi.org/10.1007/s00231-020-02835-8

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02835-8