Abstract

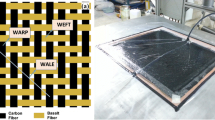

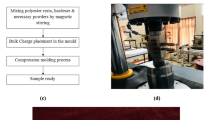

Current study investigated the effect of thermal fatigue on mechanical and thermal properties of basalt fibre-reinforced polymer (BFRP) composites. To this, basalt fibre textiles in 2/2 twill pattern was used to fabricate BFRP composites. Thermal cycling experiment was carried out between \(-40\) and \(+120^{\circ }\)C for 20, 40, 60, 80 and 120 cycles. Moreover, dynamic mechanical analyzer (DMA) was used to evaluate the effect of thermal cycling on thermal properties of BFRPs. Moreover, we compared the extracted viscoelastic characteristics, such as storage modulus, loss modulus and loss factor curves with original thermal-treated BFRP specimens. Based on the results, thermal cycling affected the characteristics of composites in the post-curing stage due to an increase in temperature. Finally, the effect of thermal cycling on water absorption properties of BFRP composites was examined by hydrophobicity test. The results showed that tensile strength, flexural modulus and ILSS values increased with the increase in the number of cycles up to 80 cycles. In other words, an increase in the number of cycles increased the hydrophobicity of BFRP composites by decreasing the contact angles. Finally, the mechanical properties of tested composites were significantly decreased when the number of cycles reached 120. This was due to the mismatch of thermal expansion coefficient and long crack formation in the structure of composite.

Similar content being viewed by others

References

Saheb D N and Jog J P 1999 Adv. Polym. Tech. 18 351

Lee J H, Rhee K Y and Park S J 2010 Mater. Sci. Eng. A 527 6838

Kalam A, Saharib B B, Khalid Y A and Wong S V 2005 Compos. Struct. 71 34

Artemenko S E and Kadykova Y A 2008 Fibre Chem. 40 37

Dai J, Pellaton D and Hahn H T 2003 Polym. Compos. 24 672

Dong C, Ranaweera-Jayawardena H A and Davies I J 2012 Compos. Part B 43 573

Wei B, Cao H L and Song S H 2011 Corros. Sci. 53 426

Czigany T 2006 Compos. Sci. Tech. 66 3210

Liu Q, Shaw M T, Parnas R S and McDonell A M 2006 Polym. Compos. 27 475

Rout J, Misra M, Tripathy S S, Nayak S K and Mohanty A K 2011 Compos. Sci. Tech. 61 1303

Alavudeen A, Rajini N, Karthikeyan S, Thiruchitrambalam M and Venkateshwaren N 2015 Mater. Des. 66 246

Carmisciano S, De Rosa I M, Sarasini F, Tamburrano A and Valente M 2011 Mater. Des. 32 337

Nayak S K, Mohanty S and Samal S K 2009 Mater. Sci. Eng. A 523 32

Silva R V, Aquino E M F, Rodrigues L P S and Barros A R F 2009 J. Reinf. Plast. Compos. 28 1857

Demir H, Atikler U, Balköse D and Tıhmınlıoğlu F 2006 Compos. Part A: Appl. S. Man. 37 447

Zhong L X, Fu S Y, Zhou X S and Zhan H Y 2011 Compos. Part A: Appl. S. Man.42 244

Sarasini F, Tirillò J, Valente M, Ferrante L, Cioffi S, Iannace S et al 2013 Mater. Des. 49 290

Szabo J S and Czigany T 2003 Polym. Test. 22 711

Zhang H, Zhang Z and Breidt C 2004 Compos. Sci. Tech. 64 2021

Dhand V, Mittal G, Rhee K Y, Park S J and Hui D 2015 Compos. Part B Eng. 73 166

Quagliarini E, Monni F, Lenci S and Bondioli F 2012 Construct. Build. Mater. 34 372

Zhang L, Du W, Nautiyal A, Liu Z and Zhang X 2018 Sci. China Mater. 61 303

Lobanov D S and Slovikov S V 2018 Mech. Compos. Mater. 54 351

Ramachandran B E, Velpari V and Balasubramanian N 1981 J. Mater. Sci. 16 3393

Sim J, Park C and Moon D Y 2005 Compos. Part B Eng. 36 504

Fiore V, Di Bella G and Valenza A 2011 Mater. Des. 32 2091

Fiore V, Scalici T, Di Bella G and Valenza A 2015 Compos. Part B Eng.74 74

Wei B, Cao H L and Song S H 2010 Mater. Des. 31 4244

Lu Z, Xian G and Li H 2016 Construct. Build. Mater. 127 1029

Qiang L, Montgomery T S and Parnas R S 2006 Polym. Compos. 27 475

Botev M, Betchev H, Bikiaris D and Panayiotou C 1999 J. Appl. Polym. Sci. 74 523

Chandekar G S and Kelkar A D 2014 Sci. World. J. 2014 1

Tehrani-Dehkordi M, Nosraty H and Rajabzadeh M H 2015 Fiber. Polym.16 918

Lopresto V, Leone C and De Iorio I 2011 Compos. Part B 42 717

Zhang Y, Yu C, Chu P K, Lv F, Zhang C, Ji J et al H 2012 Mater. Chem. Phys. 133 845

Azimpour Shishevan F and Akbulut H 2019 Iran J. Sci. Tech. Trans. Mech. Eng. 43 225

Kim H 2012 Fiber. Polym. 13 762

Kim H 2014 Fiber. Polym.14 1311

Liu Q, Shaw M T, Parnas R S and McDonnel A M 2006 Polym. Compos. 27 41

Azimpour F, Akbulut H and Mohtadi-Bonab M A 2017 J. Mater. Eng. Perform. 26 2890

Ray B C 2006 J. Appl. Polym. Sci. 100 2062

He J, Shi J, Cao X and Hu Y 2018 Adv. Civil Eng. 2018 1

Mikata Y and Taya M 1985 J. Comp. Mat. 19 554

Azimpour-Shishevan F, Akbulut H and Mohtadi-Bonab M A 2019 J. Dyn. Behav. Mater. 5 161

Kmita G, Nowak T and Sekula R 2012 Appl. Compos. Mater. 19 65

Chu Y H, Fu Q, Li H and Li K 2011 J. Alloys Compd. 509 8111

Wei L, Zhenhu C, Ding C, Cang F and Canrang W 2010 J. Alloys Compd. 504 522

Ramanujam N, Vaddadi P, Nakamura T and Singh R P 2008 Compos. Struct. 85 175

Asp L E, Berglund L A and Talreja R 1996 Compos. Sci. Tech. 56 1089

Ronga M Z, Zhang M Q and Liu Y 2006 Compos. Sci. Tech. 61 1437

Eslami-Farsani R, Khalili S M R and Najafi M 2013 J. Therm. Str. 36 684

Griffiths R and Ball A 2000 Compos. Sci. Tech. 60 2747

Segovia F, Ferrer C, Salvador M D and Amigó V 2001 Polym. Degrad. Stabil. 71 179

Komalan C, George K E, Kumar P A S and Varughese K 2007 Exp. Polym. Let. 1 641

Yu Q, Chen P, Gao Y, Mu J, Chen Y, Lu C et al 2011 Mater. Chem. Phys. 130 1046

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Azimpour-Shishevan, F., Akbulut, H. & Mohtadi-Bonab, M.A. Effect of thermal cycling on mechanical and thermal properties of basalt fibre-reinforced epoxy composites. Bull Mater Sci 43, 88 (2020). https://doi.org/10.1007/s12034-020-2059-y

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12034-020-2059-y