Abstract

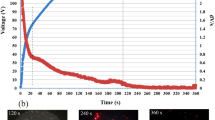

In order to enhance the corrosion resistance of molybdate conversion coating, the molybdate coating is subjected to micro-arc oxidation treatment in electrolyte with Na2SiO3 as a main salt. The electrochemical behavior and corrosion weight loss of different coating were studied. The surface morphology, element composition, roughness and phase composition of different coatings were analyzed by SEM, EDS, laser confocal microscopy and XRD, the growth process of different micro-arc oxidation coatings was explored. The results shows that the arcing voltage of the molybdate coating enhanced by micro-arc oxidation is significantly reduced, the corrosion potential is shifted to the right, and the corrosion weightlessloss of the coating is the lowest, compared with the molybdate coating and the micro-arc oxidation coating. Micro-arc oxidation on the surface of the molybdate coating is beneficial to the formation of MgAl2O4 and the production of new phase is MoSi2, which can better improve the corrosion resistance of the molybdate coating. The micro-arc oxide coating does not form a ceramic film with a pore structure at the moment of arcing. As the micro-arc oxidation time prolongs, the ceramic film is gradually formed. When the time reaches 60 s, the ceramic film is completely formed.

Graphic Abstract

In this paper, micro-arc oxidation treatment is performed on the basis of molybdate conversion coating to obtain micro-arc oxidation enhanced molybdate coating. The experiment is mainly divided into three parts: the first part, molybdate conversion treatment of the magnesium alloy substrate to obtain a molybdate conversion coating. The second part, the micro-arc oxidation treatment is performed on the surface of the molybdate coating, and discharge channels appear on the surface. The third part, micro-arc oxidation enhanced molybdate coating is obtained.

Similar content being viewed by others

References

O.B. Dormeshkin, Russ. J. Appl. Chem. 88, 1563 (2015)

Y.X. Jin, B.J. Dong, D.Q. Fang, B.W. Zhang, Rare. Met. Mater. Eng. 46, 3077 (2017)

X.Y. Peng, Y. Li, G.F. Xu, J.W. Huang, Z.M. Yin, Met. Mater. Int. 24, 1046 (2018)

E. Suneesh, M. Sivapragash, Mater. Manuf. Process. 33, 1313 (2018)

Z.Y. Yong, J. Zhu, C. Qiu, Y.L. Liu, Appl. Surf. Sci. 255, 1672 (2008)

Z.M. Zhang, X.C. Lu, Mater. Manuf. Process. 34, 591 (2019)

N.V. Phuong, M. Gupya, S. Moon, Trans. Nonferr. Met. Soc. China 27, 1087 (2017)

F. Muhaffel, H. Cimenoglu, Surf. Coat. Technol. 357, 822 (2019)

R.C. Zeng, Y. Hu, S.K. Guan, H.Z. Cui, E.H. Han, Corros. Sci. 86, 171 (2014)

S. Fintová, J. Drábiková, F. Pastorek, J. Tkacz, Surf. Coat. Technol. 357, 638 (2019)

T. Olugbade, J. Lu, Anal. Lett. 52, 2454 (2019)

T. Olugbade, J. Lu, J. Bio. Tribo. Corros. 5, 38 (2019)

V. Patel, W.Y. Li, Y.X. Xu, Mater. Manuf. Process. 34, 177 (2019)

M. Zhang, S. Cai, F.Y. Zhang, G.H. Xu, F.W. Wang, N. Yu, X.D. Wu, J. Mater. Sci.: Mater. Med. 28, 82 (2017)

M. Hilpert, L. Wagner, J. Mater. Eng. Perform. 9, 402 (2000)

K.G. Balamurugan, K. Mahadevan, Arab. J. Sci. Eng. 40, 1647 (2015)

L.H. Fu, C.F. Dong, X.G. Li, W. Han, Rare. Met. 35, 747 (2016)

M.I. Barrena, J.M. Gómez de Salazar, J.M. Vázquez, I. García-Cano, J.M. Guilemany, Met. Mater. Int. 20, 613 (2014)

M.C.L.D. Oliveira, V.S.M. Pereira, O.V. Correa, R.A. Antunes, J. Mater. Eng. Perform. 23, 593 (2013)

Z.C. Shao, F.F. Zhang, Q.F. Zhang, L. Yang, X.Y. Shen, Surf. Rev. Lett. 24, 1750012 (2017)

J. Jin, H. Li, X.H. Li, Rare. Metal. Mat. Eng. 46, 1202 (2017)

D. Seifzadeh, H.K. Mohsenabadi, Bull. Mater. Sci. 40, 407 (2017)

J.T. Xiao, A.V. Rogacheva, V.A. Yarmolenko, A.A. Rogacheva, X.H. Jiang, D.P. Sun, M.A. Yarmolenko, Surf. Coat. Technol. 349, 61 (2017)

Z.C. Shao, Z.Q. Cai, J.W. Shi, Mater. Manuf. Process. 31, 1238 (2016)

V.S. Saji, J. Ind. Eng. Chem. 75, 20 (2019)

P. Chakraborty Banerjee, R.K. Singh Raman, Y. Durandet, G. McAdam, Met. Mater. Trans. A 44, 2346 (2013)

X.R. Guan, H.D. Zhu, J.W. Shi, S.Q. Wei, Z.C. Shao, X.Y. Shen, Surf. Eng. 35, 906 (2019)

Acknowledgements

This work was supported by the Liaoning Innovation Talents in University (No. LR2017079) and Liaoning Provincial Natural Science Foundation of China (No. 20170540776).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhu, H., Li, X., Guan, X. et al. Effect of Molybdate Conversion Coating of Magnesium Alloy Reinforced by Micro-arc Oxidation. Met. Mater. Int. 27, 3975–3982 (2021). https://doi.org/10.1007/s12540-020-00656-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00656-2