Abstract

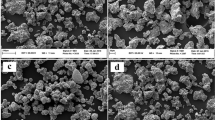

In this study, open-cell steel foams containing 0.6 wt% carbon and 2 wt% phosphorous have been manufactured through powder metallurgy route using urea granules as leachable space holder. Influences of applied pressure (100, 150, and 200 MPa), sintering temperature (1050, 1100, and 1150 °C), and sintering time (40, 50, and 60 min) on size and sphericity of the cells, pores specifications, porosity percentage, thickness and microstructure of the cells walls, and mechanical properties of the steel foam specimens were investigated. The microstructures of the cells walls were evaluated using optical microscopy and scanning electron microscopy equipped image processing software. To study the mechanical properties, compressive tests were conducted on the steel foam specimens. The averages of cells diameter, sphericity of cells, and thickness of cells walls were measured to be 0.78 mm, 0.842, and 183 µm, respectively. When the production parameters increase, the mean diameter of the pores decreases and the mean sphericity of the pores increases. Increasing the applied pressure, sintering temperature, and sintering time reduces, individually, the porosity percentage from 79.32 to 73.61%, 77.01 to 75.81%, and 77.81 to 75.12%, respectively. The microstructure of the cells walls consists of ferrite, pearlite, and iron-phosphorous phase. Iron-phosphorous phase formed at boundaries of agglomerated iron particles improves bonding, due to liquid phase sintering. Elastic region, long saw-toothed plateau region, and fracture point are observed in compressive stress versus strain curves. Increasing the applied pressure, sintering temperature, and sintering time enhances the plateau stress and absorb energy of the steel foams.

Graphic Abstract

Similar content being viewed by others

References

M.F. Ashby, A.G. Evans, N.A. Fleck, L.G. Gibson, J.W. Hutchinson, H.N.G. Wadley, Metal Foams: A Design Guide, 1st edn. (Butterworth-Heinemann, Massachusetts, 2000), pp. 26–122

H.P. Degischer, B. Kriszt, Handbook of Cellular Metals, Production, Processing and Applications, 1st edn. (Wiley-VCH/Verlag GmbH, Weinheim, 2002), pp. 12–78

J. Banhart, Prog. Mater. Sci. 46, 559 (2001)

Y. Bienvenu, Comptes. Rendus. Phys. 15(8–9), 719 (2014)

H. Utsunomiya, R. Matsumoto, Procedia Mater. Sci. 4, 245 (2014)

C. Yang, S. Kyriakides, Int. J. Solids. Struct. 159, 239 (2019)

B. Katona, A. Szlancsik, T. Tabi, I.N. Orbulov, Mater. Sci. Eng. A 739, 140 (2019)

T.M. Jeng, S.C. Tzeng, T.C. Liu, Int. J. Heat. Mass. Transf. 51, 1205 (2008)

D. Guan, J.H. Wu, J.L. Wu, J. Li, W. Zhao, Appl. Acoust. 87, 103 (2015)

Y. Huang, M. Luo, Z. Xu, D. Zhang, L. Li, Sep. Purif. Technol. 211, 269 (2019)

X. Liu, W. Zhou, Y. Lin, L. Chen, X. Chu, T. Zheng, S. Wan, J. Lin, Appl. Energy 246, 24 (2019)

G.F. Yang, S.K. Joo, Electrochim. Acta. 170, 263 (2015)

J. Banhart, Production of Metal Foams: Handbook of Comprehensive Composite Materials II, 1st edn. (Academic Press, Oxford, 2018), pp. 10–19

S. Kim, C.W. Lee, Proc. Mat. Sci. 4, 305 (2014)

B.H. Smith, S. Szyniszewski, J.F. Hajjar, B.W. Schafer, S.R. Arwade, J. Constr. Steel. Res. 71, 1 (2012)

C. Park, S.R. Nutt, Mater. Sci. Eng. A 288, 111 (2000)

C. Park, S.R. Nutt, Mater. Sci. Eng. A 297, 62 (2001)

H. Sazegaran, A.R. Kiani-Rashid, J.V. Khaki, Int. J. Min. Met. Mater. 23(4), 434 (2016)

H. Sazegaran, A.R. Kiani-Rashid, J.V. Khaki, Int. J. Min. Met. Mater. 23(6), 676 (2016)

M. Mirzaei, M.H. Paydar, Mater. Des. 121, 442 (2017)

N. Bekoz, E. Oktay, Mater. Des. 53, 482 (2014)

N. Bekoz, E. Oktay, Mater. Sci. Eng. A 576, 82 (2013)

N. Bekoz, E. Oktay, J. Mater. Process. Technol. 212, 2109 (2012)

M.H. Golabgir, R. Ebrahimi-Kahrizsangi, O. Torabi, H. Tajizadegan, A. Jamshidi, Adv. Powder. Technol. 25, 960 (2014)

Z.W. Xu, C.C. Jia, C.J. Kuang, X.H. Qu, Int. J. Miner. Metall. Mater. 17(4), 423 (2010)

L. Vendra, B. Neville, A. Rabiei, Mater. Sci. Eng. A 517, 146 (2009)

S.V. Raj, L.J. Ghosn, B.A. Lerch, M. Hebsur, L.M. Cosgriff, J. Fedor, Mater. Sci. Eng. A 456(1–2), 305 (2007)

A. Hassani, A. Habibolahzadeh, H. Bafti, Mater. Des. 40, 510 (2012)

D. Tian, Y. Pang, L. Yu, L. Sun, Int. J. Min. Met. Mater. 23(7), 793 (2016)

M. Sharma, G.K. Gupta, O.P. Modi, B.K. Prasad, A.K. Gupta, Mater. Lett. 65, 3199 (2011)

B. Jiang, N. Zhao, C. Shi, J. Li, Scr. Mater. 53, 781 (2005)

H. Sazegaran, M. Hojati, Int. J. Min. Met. Mater. 26(5), 588 (2019)

H. Sazegaran, A. Feizi, M. Hojati, Trans. Indian. Inst. Met. 72(10), 2819 (2019)

A. Noorsyakirah, M. Mazlan, O.M. Afian, M.A. Aswad, S.M. Jabir, M.Z. Nurazilah, N.H.M. Afiq, M. Bakar, A.J.M. Nizam, O.A. Zahid, M.H.M. Bakri, Procedia Chem. 19, 552 (2016)

G. Jia, Y. Hou, C. Chen, J. Niu, H. Zhang, H. Huang, M. Xiong, M. Yuan, Mater. Des. 140, 106 (2018)

B. Xie, Y.Z. Fan, T.Z. Mu, B. Deng, Mater. Sci. Eng. A 708, 419 (2017)

N. Takata, K. Uematsu, M. Kobashi, Mater. Sci. Eng. A 697, 66 (2017)

E.E. Asik, S. Bor, Mater. Sci. Eng. A 621, 157 (2015)

T. Shimizu, K. Matsuzaki, H. Nagai, N. Kanetake, Mater. Sci. Eng. A 558, 343 (2012)

J. Kadkhodapour, H. Montazerian, M. Samadi, S. Schmauder, A.A. Mehrizi, Mater. Des. 83, 352 (2015)

I. Mutlu, E. Oktay, Mater. Des. 44, 274 (2013)

D.P. Mondal, H. Jain, S. Das, A.K. Jha, Mater. Des. 88, 430 (2015)

H. Bafti, A. Habibolahzadeh, Mater. Des. 31, 4122 (2010)

M. Mirzaei, M.H. Paydar, J. Mater. Eng. Perform. 28(1), 221 (2019)

G.L. Fridman, Metallurgist 13(1), 59 (1969)

J. Capek, D. Vojtech, Mater. Sci. Eng. C 43, 494 (2014)

G.A. Baglyuk, L.A. Sosnovskii, V.I. Volfman, Powder. Metal. Met. Ceram. 50, 189 (2011)

S. Narayan, A. Rajeshkannan, Int. J. Adv. Manuf. Technol. 64(1–4), 105 (2013)

H. Jain, G. Gupta, R. Kumar, D.P. Mondal, Mater. Chem. Phys. 223, 737 (2019)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sazegaran, H. Investigation on Production Parameters of Steel Foam Manufactured Through Powder Metallurgical Space Holder Technique. Met. Mater. Int. 27, 3371–3384 (2021). https://doi.org/10.1007/s12540-020-00659-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00659-z