Abstract

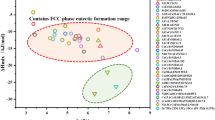

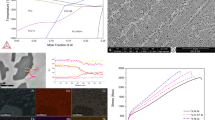

In the present work, a simple approach is proposed for predicting the compositions of eutectic high entropy alloys (EHEAs) in Al–Co–Cr–Fe–Ni system. It is proposed that eutectic lines exist between certain eutectic alloys in this system and, as a result, new eutectic or near-eutectic compositions can be obtained by mixing the alloys which are located on the same eutectic line. The approach is applied for a series of experimentally verified eutectic alloys and new eutectic or near-eutectic alloys are designed for Al–Co–Cr–Fe–Ni system. Furthermore, by investigating the compositions of verified eutectic alloys in Al–Co–Cr–Fe–Ni system, compositional maps are proposed which show the relations between the concentrations of constituent elements in eutectic alloys. The compositional maps suggest that EHEAs are derived from binary and ternary eutectic alloys. Moreover, the proposed diagrams can be considered as convenient methods for evaluating the composition of EHEAs in Al–Co–Cr–Fe–Ni system.

Graphic Abstract

Similar content being viewed by others

References

E.P. George, D. Raabe, R.O. Ritchie, High-entropy alloys. Nat. Rev. Mater. 4, 515 (2019)

D.B. Miracle, High entropy alloys as a bold step forward in alloy development. Nat. Commun. 10, 1805 (2019)

D.B. Miracle, O.N. Senkov, A critical review of high entropy alloys and related concepts. Acta Mater. 122, 448 (2017)

Y. Zhang, T.T. Zuo, Z. Tang, M.C. Gao, K.A. Dahmen, P.K. Liaw, Z.P. Lu, Microstructures and properties of high-entropy alloys. Prog. Mater. Sci. 61, 1 (2014)

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, Y. Yang, High-entropy alloy: challenges and prospects. Mater. Today 19, 349 (2016)

Y. Lu, Y. Dong, S. Guo, L. Jiang, H. Kang, T. Wang, B. Wen, Z. Wang, J. Jie, Z. Cao, H. Ruan, T. Li, A promising new class of high-temperature alloys: eutectic high-entropy alloys. Sci. Rep. 4, 6200 (2014)

X. Gao, Y. Lu, B. Zhang, N. Liang, G. Wu, G. Sha, J. Liu, Y. Zhao, Microstructural origins of high strength and high ductility in an AlCoCrFeNi2.1 eutectic high-entropy alloy. Acta Mater. 141, 59 (2017)

I.S. Wani, T. Bhattacharjee, S. Sheikh, P.P. Bhattacharjee, S. Guo, N. Tsuji, Tailoring nanostructures and mechanical properties of AlCoCrFeNi2.1 eutectic high entropy alloy using thermo-mechanical processing. Mater. Sci. Eng. A 675, 99 (2016)

F. He, Z. Wang, P. Cheng, Q. Wang, J. Li, Y. Dang, J. Wang, C.T. Liu, Designing eutectic high entropy alloys of CoCrFeNiNbx. J. Alloys Compd. 656, 284 (2016)

Y. Lu, X. Gao, L. Jiang, Z. Chen, T. Wang, J. Jie, H. Kang, Y. Zhang, S. Guo, H. Ruan, Y. Zhao, Z. Cao, T. Li, Directly cast bulk eutectic and near-eutectic high entropy alloys with balanced strength and ductility in a wide temperature range. Acta Mater. 124, 143 (2017)

I. Baker, M. Wu, Z. Wang, Eutectic/eutectoid multi-principle component alloys: a review. Mater. Charact. 147, 545 (2019)

D. Liu, P. Yu, G. Li, P.K. Liaw, R. Liu, High-temperature high-entropy alloys AlxCo15Cr15Ni70−x based on the Al–Ni binary system. Mater. Sci. Eng. A 724, 283 (2018)

X. Jin, Y. Zhou, L. Zhang, X. Du, B. Li, A novel Fe20Co20Ni41Al19 eutectic high entropy alloy with excellent tensile properties. Mater. Lett. 216, 144 (2018)

M. Wu, S. Wang, H. Huang, D. Shu, B. Sun, CALPHAD aided eutectic high-entropy alloy design. Mater. Lett. 262, 127175 (2020)

A. Patel, I. Wani, S.R. Reddy, S. Narayanaswamy, A. Lozinko, R. Saha, S. Guo, P.P. Bhattacharjee, Strain-path controlled microstructure, texture and hardness evolution in cryo-deformed AlCoCrFeNi2.1 eutectic high entropy alloy. Intermetallics 97, 12 (2018)

Y. Lu, H. Jiang, S. Guo, T. Wang, Z. Cao, T. Li, A new strategy to design eutectic high-entropy alloys using mixing enthalpy. Intermetallics 91, 124 (2017)

H. Jiang, K. Han, X. Gao, Y. Lu, Z. Cao, M.C. Gao, J.A. Hawk, T. Li, A new strategy to design eutectic high-entropy alloys using simple mixture method. Mater. Des. 142, 101 (2018)

X. Jin, Y. Zhou, L. Zhang, X. Dua, B. Li, A new pseudo binary strategy to design eutectic high entropy alloys using mixing enthalpy and valence electron concentration. Mater. Des. 143, 49 (2018)

JMatPro (Java-based Materials Property simulation software, version 7.0.0) , Sente Software Ltd., Surrey Technology Center, 40 Occam Road, Guildford, Surrey GU2 7YG, UK

N. D’Souza, H.B. Dong, Solidification path in third-generation Ni-based superalloys with an emphasis on last stage solidification. Scr. Mater. 56, 41 (2007)

N. Saunders, U.K.Z. Guo, X. Li, A.P. Miodownik, JPh Schillé, Using JMatPro to model materials properties and behavior. JOM 55, 60 (2003)

Z. Guo, N. Saunders, A.P. Miodownik, J. Ph, Schille: Modelling of materials properties and behaviour critical to casting simulation. Mater. Sci. Eng. A 413, 465 (2005)

N. D’Souza, M. Lekstrom, H.B. Dong, An analysis of measurement of solute segregation in Ni-base superalloys using X-ray spectroscopy. Mat. Sci. Eng. A 460, 258 (2008)

Z. Guo, N. Saunders, J.P. Schillé, A.P. Miodownik, Material properties for process simulation. Mater. Sci. Eng. A 499, 7 (2009)

A. Shafiei, S. Rajabi, A cobalt-rich eutectic high-entropy alloy in the system Al–Co–Cr–Fe–Ni. Appl. Phys. A 125, 783 (2019)

L. Zhang, Y. Du, Thermodynamic description of the Al–Fe–Ni system over the whole composition and temperature ranges: Modeling coupled with key experiment. Calphad 31, 529 (2007)

N. Dupin, I. Ansara, B. Sundman, Thermodynamic re-assessment of the ternary system AI–Cr–Ni. Calphad 25, 279 (2001)

Y. Wang, G. Cacciamani, Thermodynamic modeling of the Al–Cr–Ni system over the entire composition and temperature range. J. Alloys Compd. 688, 422 (2016)

G. Effenberg and S. Ilyenko (Eds.): Light Metal Systems. Part 1: Selected Systems from Ag–Al–Cu to Al–Cu–Er (Springer, Berlin, 2004), pp. 246, 288

Y. Wang, G. Cacciamani, Experimental investigation and thermodynamic assessment of the Al–Co–Ni system. Calphad 61, 198 (2018)

L. Zhu, S. Soto-Medina, R.G. Hennig, M.V. Manuel, Experimental investigation of the Al–Co–Fe phase diagram over the whole composition range. J. Alloys Compd. 815, 152110 (2020)

G. Effenberg and S. Ilyenko (Eds.): Light Metal Systems. Part 1: Selected Systems from Ag–Al–Cu to Al–Cu–Er (Springer, Berlin, 2004), pp. 206, 216

H. Baker (ed.), ASM Handbook, Alloy Phase Diagrams (ASM International, Materials Park, Ohio, 1992)

X.L. Liu, G. Lindwall, T. Gheno, Z.K. Liu, Thermodynamic modeling of Al–Co–Cr, Al–Co–Ni, Co–Cr–Ni ternary systems towards a description for Al–Co–Cr–Ni. Calphad 52, 125 (2016)

X. Jin, J. Bi, L. Zhang, Y. Zhou, X. Du, Y. Liang, B. Li, A new CrFeNi2Al eutectic high entropy alloy system with excellent mechanical properties. J. Alloys Compd. 770, 655 (2019)

Z. Yang, Z. Wang, Q. Wu, T. Zheng, P. Zhao, J. Zhao, J. Chen, Enhancing the mechanical properties of casting eutectic high entropy alloys with Mo addition. Appl. Phys. A 125, 208 (2019)

Q. Wu, Z. Wang, X. Hu, T. Zheng, Z. Yang, F. He, J. Li, J. Wang, Uncovering the eutectics design by machine learning in the Al–Co–Cr–Fe–Ni high entropy system. Acta Mater. 182, 278 (2020)

M.C. Gao, J. W. Yeh, P.K. Liaw, Y. Zhang (editors): High-entropy alloys: fundamentals and applications, 1st ed. (Springer, Cham, Switzerland, 2016), pp. 399, 444.

C. Zhang, F. Zhang, S. Chen, W. Cao, Computational thermodynamics aided high-entropy alloy design. JOM 64, 839 (2012)

F. Zhang, C. Zhang, S.L. Chen, J. Zhu, W.S. Cao, U.R. Kattner, An understanding of high entropy alloys from phase diagram calculations. Calphad 45, 1 (2014)

O.N. Senkov, J.D. Miller, D.B. Miracles, C. Woodward, Accelerated exploration of multi-principal element alloys for structural applications. Calphad 50, 32 (2015)

C. Zhang, F. Zhang, H. Diao, M.C. Gao, Z. Tang, P.K. Liaw, Understanding phase stability of Al–Co–Cr–Fe–Ni high entropy alloys. Mater. Des. 109, 425 (2016)

M.C. Gao, C. Zhang, P. Gao, F. Zhang, L.Z. Ouyang, M. Widom, J.A. Hawk, Thermodynamics of concentrated solid solution alloys. Curr. Opin. Solid State Mater. Sci. 21, 238 (2017)

T. Yang, S. Xia, S. Liu, C. Wang, S. Liu, Y. Zhang, J. Xue, S. Yan, Y. Wang, Effects of AL addition on microstructure and mechanical properties of AlxCoCrFeNi high entropy alloy. Mater. Sci. Eng. A 648, 15 (2015)

W.R. Wang, W.L. Wang, S.C. Wang, Y.C. Tsai, C.H. Lai, J.W. Yeh, Effects of Al addition on the microstructure and mechanical property of AlxCoCrFeNi high-entropy alloys. Intermetallics 26, 44 (2012)

Y. Zhou, X. Jin, L. Zhang, X. Du, B. Li, A hierarchical nanostructured Fe34Cr34Ni14Al14Co4 high-entropy alloy with good compressive mechanical properties. Mater. Sci. Eng. A 716, 235 (2018)

C. Li, Y. Ma, J. Hao, Q. Wang, S. Pang, C. Dong, P.K. Liaw, Effect of Ti substitution for Al on the cuboidal nanoprecipitates in Al0.7NiCoFeCr2 high-entropy alloys. J. Mater. Res. 33, 3266 (2018)

X. Chen, Y. Sui, J. Qi, Y. He, F. Wei, Q. Meng, Z. Sun, Microstructure of Al1.3CrFeNi eutectic high entropy alloy and oxidation behavior at 1000 °C. J. Mater. Res. 32, 2109 (2017)

Y. Ma, Q. Wang, C. Li, L.J. Santodonato, M. Feygenson, C. Dong, P.K. Liaw, Chemical short-range orders and the induced structural transition in high-entropy alloys. Scr. Mater. 144, 64 (2018)

Y. Ma, Q. Wang, B.B. Jiang, C.L. Li, J.M. Hao, X.N. Li, C. Dong, T.G. Nieh, Controlled formation of coherent cuboidal nanoprecipitates in body-centered cubic high-entropy alloys based on Al2(Ni Co, Fe, Cr)14 compositions. Acta Mater. 147, 213 (2018)

J. Hao, Y. Ma, Q. Wang, C. Zhang, C. Li, C. Dong, Q. Song, P.K. Liaw, Formation of cuboidal B2 nanoprecipitates and microstructural evolution in the body-centered-cubic Al0.7NiCoFe1.5Cr1.5 high-entropy. J. Alloys Compd. 780, 408 (2019)

M. Chen, L. Lan, X. Shi, H. Yang, M. Zhang, J. Qiao, The tribological properties of Al0.6CoCrFeNi high-entropy alloy with the σ phase precipitation at elevated temperature. J. Alloys Compd. 777, 180 (2019)

Y. Sun, C. Wu, H. Peng, Y. Liu, J. Wang, X. Su, Phase constituent and nicrohardness of as-cast and long-time annealed AlxCo2−xCrFeNi multicomponent alloys. J. Phase Equilibria Diffus. 40, 706 (2019)

T.T. Zuo, R.B. Li, X.J. Ren, Y. Zhang, Effects of Al and Si addition on the structure and properties of CoFeNi equal atomic ratio alloy. J. Magn. Magn. Mater. 371, 60 (2014)

T. Lu, W. Chai, T. Dai, Y. Pan, FeCoNiCr0.5Alx high-entropy alloys with dual-phase solidification microstructure and high compressive properties. JOM 71, 3460 (2019)

Acknowledgements

This research was supported by Niroo Research Institute (NRI) [Grant Numbers 22122 & 380115]. I thank Dr. Reza Gholamipour with the Department of Advanced Materials and Renewable Energy, Iranian Research Organization for Science and Technology (IROST) for sample preparation.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shafiei, A. Design of Eutectic High Entropy Alloys in Al–Co–Cr–Fe–Ni System. Met. Mater. Int. 27, 127–138 (2021). https://doi.org/10.1007/s12540-020-00655-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-020-00655-3