Abstract

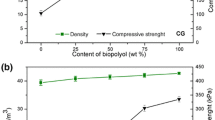

Rigid polyurethane foams of significant renewable content (up to 50%) were produced using biomass biopolyols obtained previously via crude-glycerol mediated solvothermal liquefaction of three industrial biomass residue feedstocks: digested sewage sludge, hemp stalk hurds and sugar beet pulp (DSS, HSH and SBP), and commercial diphenylmethane diisocyanate. The produced foams exhibited higher apparent densities 43–160 kg/m3 and compressive strengths 34–254 kPa compared to tested commercial analogues. Varying foam formulation isocyanate-to-hydroxyl group ratios and blending biomass biopolyols with blank crude glycerol biopolyols led to lighter and less strong products. Blank crude glycerol and DSS biopolyol foams exhibited slowest water absorption rates. Biopolyol foams exhibited higher thermal stability and the non-flame retarded foams showed lower potential for fire spread due to lower pyrolysis gas combustion heat release rates and total released amounts of heat. In terms of fire toxicity, biopolyol foams are suspected to be slightly less toxic than typical commercial PU rigid foams (CO and HCN yields of 172.2 and 6.19 mg/g, respectively), still generating significant amounts of irritant smoke in under-ventilated flaming fire scenarios. The products were stable dimensionally (below 1% elongation) and moderately biodegradable (specific rates of 0.25–0.53%/month). Overall, the foams produced show promise as sustainable alternatives in applications such as domestic construction filler foams, where low density is not crucial but fire safety is of utmost importance.

Similar content being viewed by others

References

Wei H, Roberto B (2017) Polymeric biomaterials. In: Kutz M (ed) Applied plastics engineering handbook. William Andrew Publishing, Burlington, pp 145–164

Gama Nuno V, Artur F, Ana B-T (1841) Polyurethane foams: past, present, and future. Materials 11(10):2018a. https://doi.org/10.3390/ma11101841

Smithers R (2016) High-performance polymer foams to 2021. Technical report. https://www.smithersrapra.com/market-reports/plastics-industry-market-reports/the-future-of-high-performance-foams-to-2021

Chattopadhyay DK, Raju KVSN (2007) Structural engineering of polyurethane coatings for high performance applications. Progr Polym Sci 32(3):352–418. https://doi.org/10.1016/J.PROGPOLYMSCI.2006.05.003

Desroches M, Escouvois M, Auvergne R, Caillol S, Boutevin B (2012) From vegetable oils to polyurethanes: synthetic routes to polyols and main industrial products. Polym Rev 52(1):38–79. https://doi.org/10.1080/15583724.2011.640443 ISSN 1558-3724

Briones R, Serrano L, Labidi J (2012) Valorization of some lignocellulosic agro-industrial residues to obtain biopolyols. J Chem Technol Biotechnol 87(2):244–249. https://doi.org/10.1002/jctb.2706 ISSN 02682575

Silva RV, Spinelli D, Bose Filho WW, Claro Neto S, Chierice GO, Tarpani JR (2006) Fracture toughness of natural fibers/castor oil polyurethane composites. Compos Sci Technol 66(10):1328–1335. https://doi.org/10.1016/J.COMPSCITECH.2005.10.012

Claudia M, Valdir S, Barra Guilherme MO (2011) Influence of fiber surface treatment and length on physico-chemical properties of short random banana fiber-reinforced castor oil polyurethane composites. Polym Test 30(8):833–840. https://doi.org/10.1016/J.POLYMERTESTING.2011.08.008

Fiorelli J, Curtolo DD, Barrero NG, Savastano H Jr, Pallone EM, Johnson R (2012) Particulate composite based on coconut fiber and castor oil polyurethane adhesive: an eco-efficient product. Ind Crops Prod 40:69–75. https://doi.org/10.1016/J.INDCROP.2012.02.033

Yamada T, Ono H (2001) Characterization of the products resulting from ethylene glycol liquefaction of cellulose. J Wood Sci 47(6):458–464. https://doi.org/10.1007/BF00767898

Sivakumar M, Malaisamy R, Sajitha CJ, Mohan D, Mohan V, Rangarajan R (2000) Preparation and performance of cellulose acetate-polyurethane blend membranes and their applications–II. Membr Sci 169(2):215–228. https://doi.org/10.1016/S0376-7388(99)00339-7

Wu Q, Henriksson M, Liu X, Berglund LA (2007) A high strength nanocomposite based on microcrystalline cellulose and polyurethane. Biomacromolecules 8(12):3687–3692. https://doi.org/10.1021/bm701061t

Kosmela P, Hejna A, Formela K, Haponiuk JT, Piszczyk Łukasz (2016) Biopolyols obtained via crude glycerol-based liquefaction of cellulose: their structural, rheological and thermal characterization. Cellulose 23(5):2929–2942. https://doi.org/10.1007/s10570-016-1034-7

Marina M, Filomena BM, Alessandro G (2010) Olive stone as a renewable source of biopolyols. Ind Crops Prod 32(1):7–12. https://doi.org/10.1016/J.INDCROP.2010.02.010

Shengjun H, Caixia W, Yebo L (2012) Production and characterization of biopolyols and polyurethane foams from crude glycerol based liquefaction of soybean straw. Bioresour Technol 103(1):227–233. https://doi.org/10.1016/J.BIORTECH.2011.09.125

Ju JY, Vu LH, Jinsoo K, Seung-Soo K, Yeol LE (2015) Preparation of biopolyol by liquefaction of palm kernel cake using PEG#400 blended glycerol. J Ind Eng Chem 29:304–313. https://doi.org/10.1016/J.JIEC.2015.04.010

Hoon LJ, Yeol LE (2016) Biobutanediol-mediated liquefaction of empty fruit bunch saccharification residues to prepare lignin biopolyols. Bioresour Technol 208:24–30. https://doi.org/10.1016/J.BIORTECH.2016.02.048

Luo X, Hu S, Zhang X, Li Y (2013) Thermochemical conversion of crude glycerol to biopolyols for the production of polyurethane foams. Bioresour Technol 139:323–329. https://doi.org/10.1016/j.biortech.2013.04.011

Chen F, Lu Z (2009) Liquefaction of wheat straw and preparation of rigid polyurethane foam from the liquefaction products. J Appl Polym Sci 111(1):508–516. https://doi.org/10.1002/app.29107

Marcovich NE, Kurańska M, Prociak A, Malewska E, Kulpa K (2017) Open cell semi-rigid polyurethane foams synthesized using palm oil-based bio-polyol. Ind Crops Prod 102:88–96. https://doi.org/10.1016/J.INDCROP.2017.03.025

Margarida M, Galhano R, Nieto Cs, Castro CN, De Schrijver Aster (2019) Replacement of petroleum-derived diols by sustainable biopolyols in one component polyurethane foams. J Clean Prod 212:1036–1043. https://doi.org/10.1016/j.jclepro.2018.12.088

Gama Nuno V, Belinda S, Freire Carmen SR, Rui S, Artur F, Ana B (2018b) Effect of unrefined crude glycerol composition on the properties of polyurethane foams. J Cell Plast 54:633. https://doi.org/10.1177/0021955X17732304

Qi X, Zhang Y, Chang C, Luo X, Li Y (2018) Thermal, mechanical, and morphological properties of rigid crude glycerol-based polyurethane foams reinforced with nanoclay and microcrystalline cellulose. Eur J Lipid Sci Technol 120(5):1700413. https://doi.org/10.1002/ejlt.201700413

Gama Nuno V, Rui S, Farzin M, Amin D, Amaral VS, Ferreira A, Ana B-T (2018c) Enhancement of physical and reaction to fire properties of crude glycerol polyurethane foams filled with expanded graphite. Polym Test 69:199–207. https://doi.org/10.1016/J.POLYMERTESTING.2018.05.012

Jasiūnas L, Skvorčinskienė R, Miknius L (2018) Wet and coarse: the robustness of two-stage crude glycerol mediated solvothermal liquefaction of residual biomass. Waste Biomass Valoriz pages 10:1–11. https://doi.org/10.1007/s12649-018-0453-0

Stec A, Hull T, Purser David, Purser J (2014) Fire toxicity assessment: comparison of asphyxiant yields from laboratory and large scale flaming fires. Fire Saf Sci 11:404–418. https://doi.org/10.3801/IAFSS.FSS.11-404

Wang Z, Xu S, Hu W, Xie Y (2013) Fractionation of the biopolyols from lignocellulosic biomass for the production of rigid foams. BioEnergy Res 6(3):896–902. https://doi.org/10.1007/s12155-013-9320-9

Palanisamy A (2013) Water-blown polyurethane-clay nanocomposite foams from biopolyol-effect of nanoclay on the properties. Polym Compos 34(8):1306–1312. https://doi.org/10.1002/pc.22543

Fan H, Tekeei A, Suppes GJ, Hsieh F-H (2013) Rigid polyurethane foams made from high viscosity soy-polyols. J Appl Polym Sci 127(3):1623–1629. https://doi.org/10.1002/app.37508

Jacopo B, Domenico L, Irene A, Patrizia C, Maria-Beatrice C, Claudia A, Raspolli GAM, Andrea L (2017) Exploitation of Arundo donax L. Hydrolysis residue for the green synthesis of flexible polyurethane foams. BioResources 12(2):3630–3655. https://doi.org/10.15376/biores.12.2.3630-3655

Stanzione M, Russo V, Oliviero M, Verdolotti L, Sorrentino A, Di Serio M, Tesser R, Iannace S, Lavorgna M (2018) Synthesis and characterization of sustainable polyurethane foams based on polyhydroxyls with different terminal groups. Polymer 149:134–145. https://doi.org/10.1016/J.POLYMER.2018.06.077

Nuno G, Cláudia A, Tiago S, Romeu V, João C, Ana B-T, Artur F, Nuno Vasco G, Cláudia A, Tiago S, Romeu V, Pereira CJA, Ana B-T, Artur F (2018d) Thermal energy storage and mechanical performance of crude glycerol polyurethane composite foams containing phase change materials and expandable graphite. Materials 11(10):1896. https://doi.org/10.3390/ma11101896

Muller LC, Marx S, Vosloo HCM, Fosso-Kankeu E, Chiyanzu I (2018) Rigid polyurethane foams from unrefined crude glycerol and technical lignins. Polym Renew Resour 9(3–4):111–132. https://doi.org/10.1177/2041247918803187

Yaoguang Y, Mariko Y, Nobuo S (1996) Water-absorbing polyurethane foams from liquefied starch. J Appl Polym Sci 60(11):1939–1949. https://doi.org/10.1002/(SICI)1097-4628(19960613)60:11<1939::AID-APP18>3.0.CO;2-W

Jiao L, Xiao H, Wang Q, Sun J (2013) Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS Thermal degradation characteristics of rigid polyurethane foam and the volatile products analysis with TG-FTIR-MS. Polym Degrad Stab 98(12):2687–2696. https://doi.org/10.1016/j.polymdegradstab.2013.09.032

Bastien G, Alexander M (2014) Heat release of polyurethanes containing potential flame retardants based on boron and phosphorus chemistries. Polym Degrad Stab 106:108

Huang X, De Hoop C, Xie Jiulong, Wu Qinglin, Boldor Dorin, Qi Jinqiu (2018) High bio-content polyurethane (PU) foam made from bio-polyol and cellulose nanocrystals ( CNCs ) via microwave liquefaction. Mater Des 138:11–20. https://doi.org/10.1016/j.matdes.2017.10.058

Huang X-Y, de Hoop Cornelis F, Xiao-Peng P, Long XJ, Jin-Qiu Q, Yong-Ze J, Hui X, Shuang-Xi N (2018) Thermal stability analysis of polyurethane foams made from microwave liquefaction bio-polyols with and without solid residue. BioResources 13(2):3346–3361

Usta N (2012) Investigation of fire behavior of rigid polyurethane foams containing fly ash and intumescent flame retardant by using a cone calorimeter. J Appl Polym Sci 124(4):3372–3382. https://doi.org/10.1002/app.35352

Jérôme L, Benoît B, Le Michel B, Sophie D, Christian R, Rakesh P, Franck P (2004) Flame spread of flexible polyurethane foam: comprehensive study. Polym Test 23(3):281–290. https://doi.org/10.1016/J.POLYMERTESTING.2003.08.003

McKenna ST, Hull TR (2016) The fire toxicity of polyurethane foams. Fire Sci Rev 5(1):3. https://doi.org/10.1186/s40038-016-0012-3

Jaehark G (2015) Study on the real-time size distribution of smoke particles for each fire stage by using a steady-state tube furnace method. Fire Saf J 78:96–101. https://doi.org/10.1016/J.FIRESAF.2015.08.008

Sylwia C, Bertino Massimo F, Krzysztof S (2018) Rigid polyurethane foams reinforced with industrial potato protein. Polym Test 68:135–145. https://doi.org/10.1016/J.POLYMERTESTING.2018.04.006

Fei Y, Zhiping L, Paul C, Yuhuan L, Xiangyang L, Roger R (2007) Atmospheric pressure liquefaction of dried distillers grains (DDG and making polyurethane foams from liquefied DDG). In: Klasson KT, McMillan JD (eds) Biotechnology for fuels and chemicals. Humana Press, Totowa, pp 753–761

Araceli L-T, Gerardo G-S, Raúl R-H, Aguilar Cristóbal N (2012) Microbial enzymes involved in polyurethane biodegradation: a review. J Polym Environ 20(1):258–265. https://doi.org/10.1007/s10924-011-0390-5

Acknowledgements

The authors thank UAB Mestilla, AB Nordic Sugar Kedainiai, UAB Kauno Vandenys and Endoca ApS for providing the CG, SBP, DSS and HSH, respectively. Moreover, gratitude is also expressed to Evonik for providing the foaming catalyst and surfactant. LJ thanks the research groups at the Laboratory of Biodeterioration Research of the Nature Research Centre (Lithuania) and the Centre for Fire and Hazard Science (UK) for collaborating in this study. This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors. Finally, the authors declare no competing financial interests.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Jasiūnas, L., McKenna, S.T., Bridžiuvienė, D. et al. Mechanical, Thermal Properties and Stability of Rigid Polyurethane Foams Produced with Crude-Glycerol Derived Biomass Biopolyols. J Polym Environ 28, 1378–1389 (2020). https://doi.org/10.1007/s10924-020-01686-y

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10924-020-01686-y