Abstract

The difficulty in predicting flow stress of a cold-drawn pearlitic steel wire arises from the complex microstructural transformations induced by cold drawing. For assessing properly the different contributions to strengthening, four quantities must first be expressed as a function of strain \( \varepsilon \): (i) residual volume fraction of cementite; (ii) interlamellar spacing \( \lambda \), taking initial orientation of cementite lamellae into account; (iii) carbon concentration in ferrite deduced from strain-induced carbon partitioning between ferrite and cementite; and (iv) density of dislocations. Combination of these four expressions shows that cementite is able to significantly deviate from stoichiometry before dissolving, and that dislocations alone in ferrite are not able to control the decomposition of cementite unless \( \varepsilon \) reaches 4, implying involvement of solid solution. At \( \varepsilon > 1.5 \), when all lamellae are parallel to the wire axis and Voigt model can be applied, it is found that strain hardening is negligible, ferrite hardening by carbon in solid solution is canceled out by cementite softening and flow stress is better described by the Orowan mechanism (\( 1/\lambda \) dependence) than by the Hall–Petch law (\( 1/\sqrt \lambda \) dependence).

Similar content being viewed by others

Notes

Error in formula found in the literature[77] explains why \( C\left( {x,t} \right) \) is recalculated.

References

[1] Y.J. Li, D. Raabe, M. Herbig, P. Choi, S. Goto, A. Kostka, H. Yarita, C. Borchers, R. Kirchheim: Phys. Rev. Lett., 2014, vol. 113, pp. 106104-5.

[2] J.D. Embury, R.M. Fisher: Acta Metall., 1966, vol. 14, pp. 147-159.

[3] S. Nishida, A. Yoshie, M. Imagumbai: ISIJ Int., 1998, vol. 38, pp. 177-186.

J. Gil Sevillano: Wire J. Int., 2011, vol. 44, pp. 58-70.

[5] A. Lamontagne, V. Massardier, X. Kleber, X. Sauvage, D. Mari: Mater. Sci. Eng. A, 2015, vol. 644A, pp. 105-113.

[6] X. Zhang, N. Hansen, A. Godfrey, X. Huang: Acta Mater., 2016, vol. 114, pp. 176-183.

[7] V.N. Gridnev, V.G. Gavriljuk: Phys. Met., 1982, vol. 4, pp. 531-551.

[8] J. Languillaume, G. Kapelski, B. Baudelet: Acta Mater., 1997, vol. 45, pp. 1201-1212.

[9] G.A. Nematollahi, B. Grabowski, D. Raabe, J. Neugebauer: Acta Mater., 2016, vol. 111, pp. 321-334.

[10] R.A. Johnson, G.J. Dienes, A.C. Damask: Acta Metall., 1964, vol. 12, pp. 1215-1224.

[11] D. Kalish, M. Cohen: Mater. Sci. Eng., 1970, vol. 6, pp. 156-166.

[12] E. Clouet, S. Garruchet, H. Nguyen, M. Perez, C.S. Becquart: Acta Mater., 2008, vol. 56, pp. 3450-3460.

[13] Y.J. Li, P. Choi, C. Borchers, S. Westerkamp, S. Goto, D. Raabe, R. Kirchheim: Acta Mater., 2011, vol. 59, pp. 3965-3977.

[14] X. Sauvage, J. Copreaux, F. Danoix, D. Blavette: Phil. Mag., 2000, vol. 80, pp. 781-796.

[15] X. Sauvage, Y. Ivanisenko: J. Mater. Sci., 2007, vol. 42, pp. 1615-1621.

[16] Y.J. Li, P. Choi, C. Borchers, Y.Z. Chen, S. Goto, D. Raabe, R. Kirchheim R: Ultramicroscopy, 2011, vol. 111, pp. 628-632.

[17] L. Zhou, F. Fang, X. Zhou, Y. Tu, Z. Xie, J. Jiang: Scripta Mater., 2016, vol. 120, pp. 5-8.

[18] R.G.A. Veiga, M. Perez, C.S. Becquart, E. Clouet, C. Domain: Acta Mater., 2011, vol. 59, pp. 6963-6974.

[19] A. Lamontagne, V. Massardier, X. Sauvage, Χ. Kleber, D. Mari: Mater. Sci. Eng. A, 2016, vol. 667A, pp. 115-124.

[20] A. Taniyama, T. Takayama, M. Arai, T. Hamada: Scripta Mater., 2004, vol. 51, pp. 53-58.

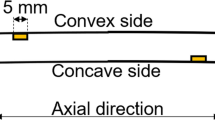

[21] A. Phelippeau, S. Pommier, I. Zakharchenko, R. Levy-Tubiana, T. Tsakalakos, M. Clavel, M. Croft, Z. Zhong, C. Prioul: Fatigue Fract. Engng Mater. Struct., 2006, vol. 29, pp. 255-265.

[22] S. Djaziri, Y. Li, G.A. Nematollahi, B. Grabowski, S. Goto, C. Kirchlechner, A. Kostka, S. Doyle, J. Neugebauer, D. Raabe, G. Dehm: Adv Mater., 2016, vol. 28, pp. 7753-7757.

[23] P. Maugis: Acta Mater., 2018, vol. 158, pp. 454-465.

[24] Y.Z. Chen, G. Csiszár, J. Cizek, C. Borchers, T. Ungár, S. Goto, R. Kirchheim: Scripta Mater., 2011, vol. 64, pp. 390-393.

[25] Y.Z. Chen, G. Csiszár, J. Cizek, S. Westerkamp, C. Borchers, T. Ungár, S. Goto, F. Liu, R. Kirchheim: Metall. Mater. Trans. A, 2013, vol. A44, pp. 3882-3889.

[26] J. Takahashi, M. Kosaka, K. Kawakami, T. Tarui: Acta Mater., 2012, vol. 60, pp. 387-395.

[27] J. Wilde, A. Cerezo, G.D.W. Smith: Scripta Mater., 2000, vol. 43, pp. 39-48.

[28] V.G. Gavriljuk: Scripta Mater., 2001, vol. 45, pp. 1469-1472.

[29] C. Borchers, R. Kirchheim: Prog. Mater. Sci., 2016, vol. 82, pp. 405-444.

[30] M.K. Miller: J. Phys., 1987, vol. 48, pp. 565-570.

[31] J. Takahashi, T. Tarui, K. Kawakami: Ultramicroscopy, 2009, vol. 109, pp. 193-199.

N. Guelton, M. François: Metall. Trans. A, 2020, https://doi.org/10.1007/s11661-020-05640-4.

[33] J. Chakraborty, M. Ghosh, R. Ranjan, G. Das, D. Das, S. Chandra: Phil. Mag., 2013, vol. 93, pp. 4598-4616.

[34] G. Langford: Metall. Trans. A, 1977, vol. 8A, pp. 861-875.

[35] G. Langford: Metall. Trans. B, 1970, vol. B1, pp. 465-477.

[36] X. Zhang, A. Godfrey, N. Hansen, X. Huang: Acta Mater., 2013, vol. 61, pp. 4898-4909.

[37] T. Teshima, M. Kosaka, K. Ushioda, N. Koga, N. Nakada: Mater. Sci. Eng. A, 2017, vol. A679, pp. 223-229.

[38] Y. Yasuda, T. Ohashi: ISIJ Int., 2016, vol. 56, pp. 2320-2326.

[39] X. Zhang, A. Godfrey, N. Hansen, X. Huang, W. Liu, Q. Liu: Mater. Charact., 2010, vol. 61, pp. 65-72.

[40] C.W. Bang, J.B. Seol, Y.S. Yang, C.G. Park: Scripta Mater., 2015, vol. 108, pp. 151-155.

[41] T. Tarui, J. Takahashi, H. Tashiro, N. Maruyama, S. Hishida: Nippon steel technical reports, 2005, vol. 91, pp. 56-61.

[42] W.J. Nam, C.M. Bae: Mater. Sci. Eng., 1995, vol. 203, pp. 278-285.

P. Watté, P. Van Houtte, E. Aernoudt, J. GilSevillano, W. Van Raemdonck, I. Lefever: Mater. Sci. Forum, 1994, vol. 157, pp. 1689-1694.

J. Alkorta, J.M. Martinez-Esnaola, P. de Jaeger, J. Gil Sevillano: 38th Risø International Symposium on Materials Science. IOP Conf. Series: Materials Science and Engineering, 2017, vol. 219, pp. 012010–8.

[45] X. Hu, P. Van Houtte, M. Liebeherr, A. Walentek, M. Seefeldt, H. Vandekinderen: Acta Mater., 2006, vol. 54, pp. 1029-1040.

[46] J.W. Park, S.D. Kim, S.P. Hong, S.I. Baik, D.S. Ko, C.Y. Lee, D.L. Lee, Y.W. Kim: Mater. Sci. Eng. A, 2011, vol. 528A, pp. 4947-4952.

[47] D. Wei, L. Li, X. Min, F. Fang, Z. Xie, J. Jiang: Mater. Charact., 2019, vol. 153, pp. 108-114.

M.H. Hong, W.T. Reynolds, T. Tarui, K. Hono: Met. Mater. Trans. A, 1999, vol. 30A, pp. 717-728.

[49] C. Borchers, T. Al-Kassab, S. Goto, R. Kirchheim: Mater. Sci. Eng. A, 2009, vol. 502A, pp. 131-138.

[50] F. Fang, Y. Zhau, P. Liu, L. Zhou, X. Hu, X. Zhou, Z. Xie: Mater. Sci. Eng. A, 2014, vol. 608A, pp. 11-15.

[51] V.I. Voronin, I.F. Berger, Y.N. Gornostyrev, V.N. Urtsev, A.R. Kuznetsov, A.V. Shmakov: JETP Lett., 2010, vol. 91, pp. 143-146.

[52] H.G. Read, W.T. Reynolds, K. Hono, T. Tarui: Scripta Mater., 1997, vol. 37, pp. 1221-1230.

[53] W.J. Nam, C.M. Bae, S.J. Oh, S.J. Kwon: Scripta Mater., 2000, vol. 42, pp. 457-463.

[54] V.G. Gavriljuk: Mater. Sci. Eng. A, 2003, vol. 345A, pp. 81-89.

[55] A.H. Cottrell, B.A. Bilby: Proc. Phys. Soc. London A, 1949, vol. 62A, pp. 49-62.

[56] A.W. Cochardt, G. Shoek, H. Wiedersich: Acta Metall., 1955, vol. 3, pp. 533-537.

[57] R.G.A. Veiga, M. Perez, C.S. Becquart, C. Domain: J. Phys.: Condens. Matter, 2013, vol. 25, pp. 025401-7.

[58] O. Waseda, R.G.A. Veiga, J. Morthomas, P. Chantrenne, C.S. Becquart, F. Ribeiro, A. Jelea, H. Goldenstein, M. Perez: Scripta Mater., 2017, vol. 129, pp. 16-19.

[59] Y. Hanlumyuang, P.A. Gordon, T. Neeraj, D.C. Chrzan: Acta Mater., 2010, vol. 58, pp. 5481-5490.

[60] K. Nakashima, M. Suzuki, Y. Futamura, T. Tsuchiyama, S. Takaki: Mater. Sci. Forum, 2006, vol. 503, pp. 627-632.

[61] J. Alkorta, J.M. Martínez-Esnaola, J. Gil Sevillano: Acta Mater., 2006, vol. 54, pp. 3445-3452.

J. GilSevillano: J. Phys. III, 1991, vol. 1, pp. 967-988.

A.D. Rollet, V.F. Kocks, J.D. Embury, M.G. Stout, R.D. Doherty: Proc. 8th Int Conf. on Strength of Metals and Alloys (ICSMA 8), 1988, vol. 1, pp. 433–38.

[64] J. Alkorta, J. Gil Sevillano: J. Mater. Res., 2012, vol. 27, pp. 45-52.

[65] G. Ghosh: AIP Advances, 2015, vol. 5, pp. 087102-19.

[66] S.A. Kim, W.L. Jonhson: Mater. Sci. Eng. A, 2007, vol. 452A, pp. 633-639.

[67] M. Janecek, F. Louchet, B. Doisneau-Cottignies, Y. Bréchet, N. Guelton: Phil. Mag., 2000, vol. 80, pp. 1605-1619.

J. Gil Sevillano: Proc. 5th Int Conf. on Strength of Metals and Alloys (ICSMA 5), 1979, vol. 2, pp. 819–825.

[69] K.H. Eckelmeyer, R.W. Hertzberg: Metall. Trans., 1972, vol. 3, pp. 609-616.

[70] F. Louchet, J. Weiss, T. Richeton: Phys. Rev. Lett., 2006, vol. 97, pp. 075504-4.

[71] Y. Li, A.J. Bushby, D.J. Dunstan: Materialia, 2018, vol. 4, pp. 182-191.

[72] X.D. Zhang, A. Godfrey, X. Huang, N. Hansen, Q. Liu: Acta Mater., 2011, vol. 59, pp. 3422-3430.

[73] A. Phelippeau, S. Pommier, T. Tsakalakos, M. Clavel, C. Prioul: Fatigue Fract. Engng Mater. Struct., 2006, vol. 29, pp. 243-253.

[74] N. Guo, B.F. Luan, B.S. Wang, Q. Liu: Sci. China Technol. Sci., 2013, vol. 56, pp. 1139-1146.

B. Gonzalez, V. Buono, E.P.E. Silva, T. Lima, M. Andrade: Proceedings of the 70th annual convention of the Wire Association International, 2000, pp. 152–56.

[76] J. Toribio, B. Gonzalez, J.C. Matos: Materials Transactions, 2014, vol. 55, pp. 93-98.

H. Mehrer: in Solutions of the Diffusion Equation (chapter 3), Diffusion in solids, Springer, Berlin, 2007, pp. 37–53.

[78] F. Danoix, D. Julien, X. Sauvage, J. Copreaux: Mater. Sci. Eng. A, 1998, vol. 250A, pp. 8-13.

[79] K. Hono, M. Ohnuma, M. Murayama, S. Nishida, A. Yoshie, T. Takahashi: Scripta Mater., 2001, vol. 44, pp. 977-983.

[80] X. Sauvage, N. Guelton, D. Blavette: Scripta Mater., 2002, vol. 46, pp. 459-464.

[81] N. Min, W. Li, H. Li, X. Jin: J. Mater. Sci. Technol., 2010, vol. 26, pp. 776-782.

[82] A. Lamontagne, X. Kleber, V. Massardier-Jourdan, D. Mari: Phil. Mag. Lett., 2014, vol. 94, pp. 495-502.

[83] N. Maruyama, T. Tarui, H. Tashiro: Scripta Mater., 2002, vol. 46, pp. 599-603.

[85] J. Toribio, E. Ovejero: Scripta Mater., 1998, vol. 39, pp. 323-328.

[86] A. Durgaprasad, S. Giri, S. Lenka, S. Kundu, S. Mishra, S. Chandra, R.D. Doherty, I. Samajdar: Metall. Mater. Trans. A, 2017, vol. 48A, pp. 4583-4597.

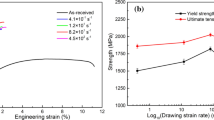

[87] Y. Zhao, Y. Tan, X. Ji, Y. He, Y. Liang, S. Xiang: JOM, 2019, vol. 71, pp. 4041-4049.

[88] G. Gershteyn, F. Nürnberger, F. Cianciosi, N. Shevchenko, M. Schaper, F.W. Bach: Steel Res. Int., 2011, vol. 82, pp. 1368-1374.

[89] S. Sato, K. Wagatsuma, M. Ishikuro, E.P. Kwon, H. Tashiro, S. Suzuki: ISIJ Int., 2013, vol. 53, pp. 673-679.

Acknowledgments

The permission for publication granted by Michel Babbit, Manager of ArcelorMittal Maizières Research/Products, and Pascal Buessler, Technical Director of ArcelorMittal Maizières Research/Bars and Wires, is gratefully acknowledged. The authors also thank Professor John David Embury of McMaster University, Thierry Iung, Manager of Metallurgy Team in ArcelorMittal Maizières Research, Xavier Sauvage, Research Director at French National Center for Scientific Research, Roberto Gomes de Aguiar Veiga, Assistant Professor at the Federal University of ABC, for helpful suggestions. At last, the authors thank an anonymous referee for giving a mathematical expression of strain-dependent interlamellar spacing, much more elegant than that they initially submitted to the Journal.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Manuscript submitted September 17, 2019.

Appendices

Appendix A: Bibliographic Data

This appendix compiles experimental data derived from literature: carbon concentration in cementite \( C_{\theta }^{\varepsilon } \) (Table AI) and ferrite \( C_{\alpha }^{\varepsilon } \) (Table AII), interlamellar spacing \( \lambda \) (Table AIII), and dislocation density \( \rho \) (Table AIV). Experimental values \( C_{\theta }^{\varepsilon } \), \( \lambda \) and \( \rho \) will be used for curve fitting, while experimental values \( C_{\alpha }^{\varepsilon } \) for comparison with calculated results presented in this work.

Appendix B: Expression of Interlamellar Spacing as a Function of Strain

Let \( \omega \) be the initial orientation angle between lamellae and WA (\( 0 \le \omega \le \pi /2 \)), \( \varepsilon_{\parallel }^{\omega } \) the strain required to reorientate lamellae initially misoriented by \( \omega \), parallel to WA, and consequently \( \varepsilon_{\parallel }^{\pi /2} \), the strain at which all the lamellae are parallel to WA. There is a general agreement that the realignment process is complete at \( \varepsilon_{\parallel }^{\pi /2} \cong 1.5 \), e.g. References 5, 39, and 42. Knowing equiprobability of lamellar orientation at \( \varepsilon = 0 \),[74] and nearly linear decrease in mean orientation \( \bar{\omega } \) with drawing strain, at least for \( 0 \le \varepsilon \le 1.5 \),[75,76] then a linear dependence of \( \varepsilon_{\parallel }^{\omega } \) on \( \omega \) can be reasonably assumed:

For convenience purposes, \( \varepsilon_{\parallel }^{\pi /2} \) is referred to as \( \varepsilon^{*} \). The interlamellar spacing of a colony initially misoriented by \( \omega \), as a function of strain \( \varepsilon \), is:

The mean interlamellar spacing of the wire drawn to \( \varepsilon \) is:

Knowing that \( \omega = \pi \varepsilon /\left( {2\varepsilon^{*} } \right) \) at \( \varepsilon = \varepsilon_{\parallel }^{\omega } \), and combining Eqs. [B2] and [B3]:

The mean normalized interlamellar spacing at complete realignment is \( \left( {1/\lambda_{0} } \right)\bar{\lambda }\left( {\varepsilon^{*} = 1.5} \right) = 0.7035 \). Figure B1 compares Eq. [B4] with the proportionality rule of Eq. [1] and experimental data of Table AIII. The curve of Eq. [B4] plotted for \( \varepsilon^{*} = 1.5 \) is closer to observations than the proportionality rule but the value of 1.08 that \( \varepsilon^{*} \) must take so that the curve fits experimental values is not satisfactory. The few data of Table AIII far from the overall trend were previously excluded from fitting. This too low fitted value comes from the ambiguity in the assumption of equiprobability in lamellar orientation: even if all possible orientations of the pearlite lamellae are equiprobable in the Cartesian space, it is still much more probable to find a lamella parallel to the WA, than perpendicular to it. This occurs because there is an infinite set of independent planes which are parallel to a “zone axis” (e.g. WA), but there is only one plane which is perpendicular to it. Equation [B3] is tantamount to considering equiprobability of those cementite lamellae whose normal vectors are in the plane of polar coordinates \( \left( {r,\omega } \right) \).

The normal to a cementite lamella can be represented as a vector going from the center to the surface of a hemisphere of radius 1 (Figure B2). It is not necessary to consider a full sphere since the sign of the normal vector is unimportant. The equiprobability hypothesis can be expressed by saying that all possible end-points of such vector on the hemisphere surface are equiprobable. Following this reasoning, the average value of the interlamellar spacing, in respect to all possible orientation of the pearlite lamellae, is more correctly given by an integral calculated by using spherical coordinates.

If the WA goes from the South Pole to the North Pole, \( \chi \) is the longitude (\( 0 \le \chi \le 2\pi \)), and \( \omega \) the latitude (\( 0 \le \omega \le \pi /2 \)):

The absolute value of the Jacobian, usually expressed as \( r^{2} \sin \varphi \), where \( r \) is the radial distance and \( \varphi \) the colatitude, is replaced here, in case of a hemisphere of radius 1, by \( \cos \omega \), where \( \omega \) is the latitude. The following will be useful hereafter for the integration:

if \( f\left( x \right) = \exp \left( {Ax} \right)\left[ {\sin \left( x \right) + {\text{Acos}}\left( x \right)} \right] \), then: \( f^{\prime}\left( x \right) = \left( {A^{2} + 1} \right) {\text{exp}}\left( {Ax} \right)\cos \left( x \right) \). It follows that:

By combining Eqs. [B2] and [B5]:

In this case, the mean normalized interlamellar spacing at complete realignment is \( \left( {1/\lambda_{0} } \right)\bar{\lambda }\left( {\varepsilon^{*} = 1.5} \right) = 0.6307 \). The curve of Eq. [B6] is plotted for \( \varepsilon^{*} = 1.5 \) in Figure 2. When this equation is fitted to the experimental points, \( \varepsilon^{*} \) takes the value of 1.49. This result confirms not only that Eq. [B6] describes very well the deck-of-card mechanism but also that the reorientation is complete at \( \varepsilon = 1.5 \).

Remark 1

From Eqs (B4) and (B6), it can be easily deduced that:

Remark 2

It is customary to suppose that the mean initial angle of cementite lamellae with respect to WA is 45 deg. This is true only in case of planar representation, in polar coordinates, i.e. if are considered only lamellae whose normal vectors are in the plane \( \left( {r,\omega } \right) \). In the case of spatial equiprobability, the mean initial angle is the mean latitude in a hemisphere:

with \( S \) the surface area of the hemisphere (\( 2\pi ) \) and \( ds \) the surface area of a strip surrounding the hemisphere and parallel to the equator, of width \( d\omega \) and circumference \( 2\pi \cos \left( \omega \right) \).

Appendix C: Carbon Distribution in Drawn Pearlite

The theory of diffusion, and more specifically the solution of the diffusion equation in a multilayer structure, provides a convenient formalism for describing carbon redistribution, even though dislocation-assisted transport is given more credit than time and temperature driven bulk diffusion to account for carbon-depleted cementite. This appendix proposes an analytical expression of carbon partitioning between ferrite and cementite, based on a modified analytical solution of the diffusion equation, no matter how carbon may be transported and wherever it may be accommodated. Carbon concentration in any plane parallel to the α/θ interface is supposed uniform. In other words, carbon fluctuation observed in cementite by probing parallel to the lamellae[5] is ignored.

If an infinitesimally thin layer of the diffusing species is deposited at the plane \( x = 0 \) sandwiched between two semi-infinite media, the concentration \( C\left( {x,t} \right) \) (quantity of matter per unit volume) as a function of time t and position x is:

where Q0 is the quantity of diffusing species per unit area and D the diffusion coefficient. This solution, which is a Gaussian distribution whose standard deviation is \( s = \sqrt {2Dt} \), is only valid if the thickness of the diffusant is small with respect to s. This is not the case of pearlite whose lamella thickness ratio is at \( \varepsilon = 0 \) (lever rule):

where \( C_{s} \) is the carbon concentration in steel (3.7 at. pct), and \( C_{\alpha }^{0} \) and \( C_{\theta }^{0} \) the carbon concentration in ferrite (0.06 at. pct) and cementite (25 at. pct). Considering that a layer of thickness h can be obtained by juxtaposing layers of infinitesimal thickness dη, between two semi-infinite media, the diffusion field can be expressed by an integral of the source distribution given by Eq. [C1]:

where C0 is the uniform initial concentration of the diffusant. Equation [C3] applies if the layer and the two media sandwiching it have the same diffusivity, which is certainly not true for ferrite and cementite whose crystal lattices are different. Once again, attention is focused only on the analytical expression of the solution of the diffusion equation.

Let u be a substitution variable: \( u = \left( {x - \eta } \right)/\left( {2\sqrt {Dt} } \right) \). Equation [C3] becomes:

The integral is split in order to introduce the convenient error function:

The solution is thus given byFootnote 1:

In the case of drawn pearlite where carbon transport does not depend on time and temperature but rather on strain, \( \sqrt {Dt} \) is replaced by \( s_{\varepsilon } \), a strain-dependent standard deviation characterizing the width of the distribution, and \( h \) by the cementite thickness \( t_{\theta }^{\varepsilon } \) which also depends on strain. Equation [C6] rewrites:

where

Three corrections must be made to Eq. [C7] to take into account (i) the microstructural scale reduction by drawing, (ii) the finite half-thickness of ferrite lamellae and (iii) the initial carbon content in ferrite.

(i) Scale reduction. \( t_{\theta }^{\varepsilon } \) decreases in accordance with the scale factor F given by Eq. [2]:

with the initial volume fraction of cementite \( f_{\theta }^{0} = \left( {C_{s} - C_{\alpha }^{0} } \right)/\left( {C_{\theta }^{0} - C_{\alpha }^{0} } \right) \). Spread of carbon distribution, whose consequence is cementite dissolution, comes in addition to the scale reduction. It is thus important to dissociate the effect of microstructural refinement from that of carbon transport and, in order to prevent the change of scale from artificially broadening the carbon distribution, \( s_{\varepsilon } \) should be also expressed as a function of the scale factor: \( s_{\varepsilon } = \sigma_{\varepsilon } F\left( \varepsilon \right) \). In this way, for a given distribution \( \sigma_{\varepsilon } \), the shape of the distribution is independent of the scale of observation and carbon transport only controlled by \( \sigma_{\varepsilon } \).

(ii) Multilayer periodic structure. The way the periodicity of the lamellar structure is taken into account is explained in Figure C1. The diffusion fields centered on the cementite lamellae meet each other at \( \lambda_{\varepsilon } /2\, \left( {{\text{modulo}} \,\lambda_{\varepsilon } } \right) \). Soft impingement is neglected, i.e. no slowdown in transport is taken into account, and the carbon transported outside the interval \( \left[ { - \lambda_{\varepsilon } /2; + \lambda_{\varepsilon } /2} \right] \) and represented by the area under the curve A2 shall be returned to it:

A2 is deduced from the definite integral A1 of the distribution given by Eq. [C7] and the conservation of mass:

Let \( u = \left( {x + t_{\theta }^{\varepsilon } /2} \right)/\left( {s_{\varepsilon } \sqrt 2 } \right) \) and \( v = \left( {x - t_{\theta }^{\varepsilon } /2} \right)/\left( {s_{\varepsilon } \sqrt 2 } \right) \). Equation [C11] rewrites:

Knowing that integration of erf(u) by parts and substitution is:

The area \( A_{1} \) under the curve is:

With:

Combining Eqs. [C10], [C12] and [C15], the carbon concentration in a drawn lamellar pearlite is finally:

(iii) Carbon content in ferrite. Introduction of \( C_{\alpha }^{0} \) in the solution is straightforward. Equation [C17] becomes:

It can be easily checked that mass is conserved throughout the drawing:

Equation [C18] offers the advantage of simplicity and ease of use. It has only one parameter to be determined, namely \( \sigma_{\varepsilon } \), which can be easily fitted to experimental values of the strain-dependent maximum carbon concentration in cementite, given that the maximum of carbon distribution is always at \( x = 0 \): \( C\left( {0,\varepsilon } \right) = \hbox{max} \left( {C_{\theta }^{\varepsilon } } \right) \). \( \hbox{Max} \left( {C_{\theta }^{\varepsilon } } \right) \), compiled in Table AI, is plotted against the true strain in Figure C2.

It is known that the inhomogeneous cementite decomposition is mainly due to the random initial lamellar orientation (Section II–A) and that the material itself (chemical composition, thermal treatment prior to drawing) and its processing (pass schedule, lubrication, speed, etc.) can also explain the variation in results among studies, but Figure C2 clearly shows that the APT sample preparation method adds further uncertainty. If the lamellae are parallel to the needle, the highest margin of error is 15 at. pct and drops to 5 at. pct if they are perpendicular to the needle. Despite dispersion in materials studied in the literature and local heterogeneities inherent to the realignment process of lamellae, APT measurements performed in cementite lamellae with probing direction perpendicular to WA follow a clear low-scattered downward trend. Best fit to carbon concentration measured by APT in cementite lamellae perpendicular to the probing direction is provided by the Rosin-Rammler function (Figure C2):

Once again, there is a change in curvature at \( \varepsilon = 1.5 \), reflecting an acceleration of cementite dissolution after complete realignment. \( \sigma_{\varepsilon } \) is then easily deduced from this fit by iteration: for a given strain \( \varepsilon \), \( \sigma_{\varepsilon } \) is such that \( C_{\text{calc}} \left( {0,\varepsilon ,\sigma_{\varepsilon } + d\sigma_{\varepsilon } } \right) < C_{\text{meas}} \left( {0,\varepsilon } \right) \le C_{\text{calc}} \left( {0,\varepsilon ,\sigma_{\varepsilon } } \right) \).

Appendix D: Exponential Strain Dependence of Dislocation Density

The net Burgers vector produced by geometrically necessary dislocations responsible for the change in shape is easy to calculate in the simple case of uniaxial tension. Let \( [111](1\bar{1}0) \) be the only active slip system in a (100) bcc iron single crystal and n the number of dislocations gliding per plane \( (1\bar{1}0) \) (Figure D1). The supposed homogeneous shearing produces slip steps of equal height nb per unit length h. As a result of this plastic deformation, the initial thickness d0 of the specimen is reduced to d. According to Figure D1, d is expressed as a function of n and crystallographic data aα (lattice parameter equal to 0.2866 × 10−9 m), b (Burgers vector), h and θ:

with:

Given that true strain in tensile deformation of a flat specimen is \( \varepsilon = \ln \left( {d_{0} /d} \right) \) (gauge width remains constant) and mobile dislocation density is \( \rho = n/\left( {d_{0} h} \right) \), the strain dependence of \( \rho \) can be plotted by varying n and is clearly exponential (Figure D2). This simple calculation can be used to estimate \( \rho_{\text{SSD}} \) provided that \( \rho_{\text{SSD}} \) is proportional to \( \rho \) over the whole deformation. If the mean free path of dislocations \( \ell \), initially equal to \( \ell_{0} = {\text{AE}} \), is controlled by microstructure, e.g. interlamellar spacing, it will decrease with strain according to \( \ell = \ell_{0} \exp \left( { - \varepsilon } \right) \). Therefore n, and consequently \( \rho \), shall be adjusted by the factor \( \ell_{0} /\ell = \exp \varepsilon \). Figure D2 shows that the effect of the control of the mean free path of mobile dislocations by microstructure is a multiplication of \( \rho \) by two orders of magnitude at \( \varepsilon = 5 \). The saturation value of 5 × 1016 m−2 can be easily reached at \( \varepsilon = 5.6 \) especially since this calculation provides only a lower estimate of \( \rho \). Of course, such a value is unachievable in tension, due to necking limiting strain to at best 0.5.

Rights and permissions

About this article

Cite this article

Guelton, N., François, M. Microstructure–Property Relationship in Cold-Drawn Pearlitic Steel Wires. Metall Mater Trans A 51, 1543–1566 (2020). https://doi.org/10.1007/s11661-019-05613-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11661-019-05613-2