Abstract

Generally, the interface friction on solid surfaces is regarded as consistent with wetting behaviors, characterized by the contact angles. Here using molecular dynamics simulations, we find that even a small charge difference (≤0.36 e) causes a change in the friction coefficient of over an order of magnitude on two-dimensional material and lipid surfaces, despite similar contact angles. This large difference is confirmed by experimentally measuring interfacial friction of graphite and MoS2 contacting on water, using atomic force microscopy. The large variation in the friction coefficient is attributed to the different fluctuations of localized potential energy under inhomogeneous charge distribution. Our results help to understand the dynamics of two-dimensional materials and biomolecules, generally formed by atoms with small charge, including nanomaterials, such as nitrogen-doped graphene, hydrogen-terminated graphene, or MoS2, and molecular transport through cell membranes.

Similar content being viewed by others

Introduction

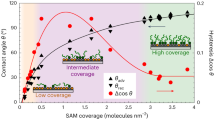

The microscopic nature of solid/liquid boundary friction has long been a subject of interest in materials and biology systems. It relates to the lubrication and nano-tribology of materials1,2,3,4,5,6,7,8,9,10, developing micro-fluidic and nano-fluidic devices11,12,13,14,15,16,17,18,19, the motion of biological molecules20,21,22 and even protein folding23. Generally, the microscopic friction is usually determined by measuring the contact angle24,25,26,27,28,29,30,31,32,33,34; a large contact angle indicating a hydrophobic surface is associated with low surface friction, and vice versa35. However, the contact angle as a macroscopic surface wetting property is not always consistent with the microscopic viewpoint, even for nano-scale wetting behaviors themselves on polar surfaces32,33,34,36. This complicates the relationship between surface friction and surface hydrophobicity/hydrophilicity.

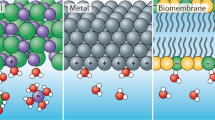

Charges below 0.36 e widely exist in atoms or groups of popular two-dimensional materials and biomolecules. For example, the carbon atoms in N-doped37,38 and the hydrogen-terminated graphene39 usually attain the charge from 0.10 e to 0.20 e, the carbon atoms of the terminal methyl of a lipid usually attain the charge of −0.18 e40,41,42, the carbon atoms of benzene rings in Phe group of protein residues can attain a charge of −0.115 e43,44, and the S atoms of MoS2 have a charge of −0.36 e45. Such small charges on the solid surfaces are usually neglected in studying the surface dynamics. This is partly because total surface–water interactions due to small charges have negligible electrostatic interaction energies, which is confirmed by the similar contact angles on these surfaces. Unfortunately, the association of solid–water interfacial friction and the wetting properties of solid charged surfaces still remain unknown.

In this work, based on the molecular dynamics simulations, we unexpectedly reveal a change in the friction coefficient of over an order of magnitude within a small charge range (≤0.36 e) even for similar contact angles. This is further confirmed by experimentally measuring interfacial friction of graphite and MoS2 contacting on the water using atomic force microscopy (AFM). The large variation in friction coefficient is attributed to the different fluctuations of localized potential along the solid surface due to the charge distributions. Meanwhile, the surface–water interaction energy per unit area almost remains constant. Particularly, we find a linear relationship between the surface friction coefficient and the fluctuations in the localized potential energy profile, (ΔEmicro)2 due to the surface charge. These results help clarifying the physical mechanism relating macro wetting behaviors and micro frictions of various surfaces, including biological surfaces.

Results and Discussion

Contact angle and frictions on a model charged solid surface

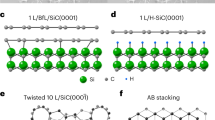

Figure 1a shows the geometry of the solid surface system with a small charge in the range 0 e–0.36 e. Positive and negative charges of the same magnitude q were assigned to atoms located diagonally on neighboring hexagons. A square-lattice model surface with a similar charge range can be found in Supplementary Note 4 of the Supplementary Information. A square-lattice model surface with a similar charge range can be found in Supplementary Note 4 in Supplementary Information. Overall, the modeled solid surface was neutral. The contact angle was determined by fitting the curve of the liquid–vapor interface, according to the method in previous work32,46. More details on the simulation setup can be found in the Methods section. The friction coefficient was calculated using the Green–Kubo relationship6,35,47:

where F(t) is the total tangential force acting along the x direction on a surface with area A and the average runs over equilibrium configurations; kB is the Boltzmann constant, T is the temperature, and λ is the friction coefficient for water on various solid surfaces for sufficiently long time intervals (1 ps), as shown in Supplementary Fig. 1 and described in Supplementary Note 1.

A hexagonal solid surface, the highly oriented pyrolytic graphite (HOPG) and MoS2 solid surfaces are shown. a Model hexagonal solid surface with small charge ranging from 0 e to 0.36 e. The red and blue spheres represent positive and negative charges, respectively, and the gray spheres represent neutral atoms. b Estimated relative friction coefficient λq/λ0 (q ≤ 0.36 e) of liquid water on the solid surface calculated with the Green–Kubo relationship (black solid columns), and relative friction calculated from the contact angle using the theory proposed by Huang et al. in ref. 35 (red textured columns), together with the contact angles in respect of the charge q values from 0.00 e to 0.36 e. When q increases from 0.00 e to 0.36 e, the Green–Kubo relative friction coefficient changes by a factor of 41 while the coefficient calculated from the contact angle changes by 50%. This panel also shows the typical materials with the atomic charge range from 0.00 e to 0.36 e, including graphene, hydrogen-terminated graphene, N-doped graphene, and MoS2. c Schematic for the measuring friction with an AFM tip. The arrow shows the moving direction of the AFM tip, which is perpendicular to the cantilever. A water droplet condenses from the humid environment between the hydrophilic AFM tip and the HOPG or MoS2. d Lateral deflection signal of the AFM cantilever when rubbing on HOPG or MoS2, respectively, varying with the relative environmental humidity. Error bars are the standard deviations of the lateral deflection signals with the “discrete frequency” larger than 200. The friction force is proportional to the lateral deflection signal”.

Figure 1b (black columns) shows the relative friction λq/λ0 as a function of the charge within the small range 0 e ≤ q ≤ 0.36 e, where λq is the friction coefficient at a particular charge q and λ0 is the friction on a neutral surface calculated with the Green–Kubo relationship. The calculated friction increases from 1.2 × 104 Ns/m3 for q = 0 e to 4.9 × 105 Ns/m3 for q = 0.36 e; the latter friction is over one order of magnitude (41 times) higher than the former. Note that this friction for q = 0.36 e is quite close to the value of ~2.0 × 105 Ns/m3 on MoS245 where the surface charge of the S atoms is −0.36 e. Figure 1b (right wine columns) shows the dependence on contact angle of the surface charge of the hexagonal lattice. When q ≤ 0.36 e, the contact angle slightly decreases from θ = 88° ± 2° for q = 0 e to θ = 68° ± 2° for q = 0.36 e, which is consistent with the fact that surface atomic charges slightly affect wetting within a small charge range48. Huang et al.35 proposed that the friction coefficient \({\it{\uplambda }}^{\ast}\) closely related to the contact angle θ according to

Figure 1b (red textured columns) shows that the relative friction \({\it{\uplambda }}_q^ \ast /{\it{\uplambda }}_{\it{0}}^ \ast\) based on the contact angles varies by only 50% as q increases from 0 e to 0.36 e. This clearly shows that a small surface charge (q ≤ 0.36 e) significantly affects the friction coefficient even similar contact angles, in contrast to the conventional viewpoint. This deviation of very high calculated friction from the low theoretical friction based on contact angles is universal, even on a square-lattice polar surface with a very small charges (see Supplementary Note 4 in the Supplementary Information).

To further understand the origin of the large change in friction coefficient, we studied the microscopic water-surface interaction in the first contact layer with the thickness of 0.50 nm (see more details of the water density in Supplementary Note 2 and Supplementary Fig. 2 in the Supplementary Information). We divided the area into small squares each with an area of 0.25 Å2 and calculated the average microscopic interaction energy Emicro of each water molecule and of all the solid surface atoms. Figure 2a shows a continuously smooth Emicro distribution over the area at q = 0 e, with almost no energy barrier to obstruct the motion of the water molecules. When q increases to 0.2 e, the colored area becomes discontinuous and separated by high and low energies. This means that the water molecules encounter energy barriers when they move, resulting in higher friction. We have plotted the distribution of Emicro in Supplementary Fig. 3 of the Supplementary Information, where Emicro has a broader distribution when the charge increases. We calculated the average total solid–water interaction energy E and found that it slightly decreases from −56 kJ mol−1nm−2 to –68 kJ mol−1nm−2 as q increases from 0 e to 0.36 e. This is consistent with the variation of the contact angle29 but quantitatively inconsistent with the very high change in friction coefficient (a factor of 41) over this range of q.

The microscopic potential energy profiles of square-lattice surfaces for different charge value q = 0 e (a), 0.1 e (b), 0.2 e (c) and 0.3 e (d) are shown in Supplementary Fig. 5. The dependence of the microscopic energy variance (ΔEmicro)2, the surface friction coefficient and the analysis of total interactions between surface-water on the surface charge q is discussed in Supplementary Note 5.

The large variation in friction coefficient is due to the large fluctuation of the localized potential energy, defined as (ΔEmicro)2 = 〈(Emicro − 〈Emicro〉)2〉, which is obtained from the standard deviation of the microscopic interaction energy Emicro under inhomogeneous charge distributions. We have established a quantitative relationship between the friction coefficient and (ΔEmicro)2, which is obtained from the standard deviation of the microscopic interaction energy Emicro. We have found that the surface friction increases monotonous as the ΔEmicro increases. Figure 3 shows a good linear relationship between the simulated friction coefficient and (ΔEmicro)2 obtained with a fitting factor ζ ~ 130 when ΔEmicro is less than 0.45 kJ/mol. On the basis of the Green–Kubo relationship of Eq. (1)35, the surface friction λ is proportional to the square of the total surface-water tangential force, 〈F〉2. The charge q of each polar solid surface uniquely determines 〈F〉2. This is different from previous work in which 〈F〉2 is proportional to the Lennard-Jones energy reflecting the solid–water interactions on atomic surfaces35. The force 〈F〉 is roughly proportional to the potential energy fluctuation ΔEmicro; thus λ ∼ (ΔEmicro)2 ∼ q2 (see the further discussion in PS 5 of the Supplementary Information). Thus, the local potential fluctuation and friction coefficient quadratically increase as q increases (see also Supplementary Figs. 6 and 7 in the Supplementary Information), which also explains the increase in the friction coefficient of MoS2 compared with that of graphene6,45. The linear relationship between λ and (ΔEmicro)2 is universal. For a square-lattice surface with a charge of around 0.3 e, we have found that the friction coefficient changes by a factor of 1000 even with a similar contact angle (see Supplementary Note 3 and Supplementary Fig. 4 in the Supplementary Information). Despite different surface lattices, Fig. 3 (black solid squares) shows a linear relationship between (ΔEmicro)2 and λ with almost the same factor of 130.

Contact angle and frictions on a bimolecular solid surface

In addition, we experimentally measured the surface friction of highly oriented pyrolytic graphite (HOPG) and MoS2 contacting on the water by rubbing a hydrophilic AFM tip with a constant loading force (see Fig. 1c and more details in the Methods). The average the lateral deflection signal on MoS2 fluctuates around 0.04 mV at different relative environmental humidity, about 6 times of that on HOPG, as shown in Fig. 1d. It indicates that the surface friction of MoS2 is about 6 times of that of HOPG since the friction force is proportional to the lateral deflection signal. We also measured the contact angles to be 83° ± 5° and 83° ± 6° on HOPG and MoS2, respectively. These experimental results support our simulation of the large variation of solid–water interfacial friction coefficient on the two two-dimensional material surfaces with the small charge and similar contact angles. We note that the experimental difference in friction between MoS2 and HOPG is less than in the simulation, which may be partly due to the different thicknesses of the water films and different lattices of these two substrate surfaces.

We note that many beta-carbon atoms in biological molecules have charges of less than 0.36 e, such as −0.115 e for the carbon atoms of benzene rings in Phe, −0.18 e for the methyl carbon atoms in Ala, −0.22 e for the sulfur atoms in Cys, and −0.32 e for the carbon atoms in benzyl methyl phosphonate49. We expect that these low charges do not affect the hydrophobicity of the backbone but greatly affect the friction of the backbone-water interface. To verify this, we simulated a surface composed of rigid methylene CH2 groups (see Fig. 4a) with qC = −0.12 e and qH = 0.06 e, which is an important backbone in lipid molecules. By rescaling the charges from 0.06 e to 0.36 e (with qC = −0.12 e corresponding to a methyl carbon atom in a lipid), we find that the variation in surface friction coefficient can even reach a factor of 4 for surfaces with similar contact angles (Fig. 4b). However, Eq. (2) yields a variation in relative friction \({\it{\uplambda }}^{\ast}\) of only 10%, in sharp contrast to the factor of 4 for solid surfaces as qC increases from 0.06 e to 0.36 e. Again, the small charge may not affect the hydrophobicity of a biological backbone composed of CH2 groups, but greatly affects the surface friction, which may be the key to protein folding and transport of biological molecules.

a Plane model of a carbon-based solid surface composed of CH2 groups. b Estimated relative friction coefficient λk/λ0.06 of liquid water on the solid surface simulated with the Green–Kubo relationship (black solid columns), relative friction calculated from contact angles in ref. 35 (red textured columns), and contact angles (wine squares) for various atoms with charges of less than 0.36 e on solid surface composed of CH2 groups. This panel also shows the various small charge carbon atoms less than 0.36 e in some typical biological protein residues.

In summary, we have found a change in friction coefficient of over an order of magnitude over a small charge range (≤0.36 e) on two-dimensional materials and lipid surfaces even with little change in contact angle. We have confirmed this by experimentally measuring the solid/water surface friction of graphite and MoS2 using AFM. This huge difference in interfacial friction is caused by the different fluctuations in localized solid–water interaction potentials along the solid surface due to the heterogeneous charge distributions. Different structures such as hexagonal and square lattices and lipid alkane groups exhibit similar deviations in contact angle and surface friction, suggesting that the phenomenon is general. More importantly, atoms with small charge are very common in materials such as nitrogen-doped graphene and MoS2. This work will thus help in accurately understanding the dynamics of these materials and facilitate their fabrication or manipulation.

Our findings show that general wetting behavior cannot be directly used to infer the friction of biological molecules. This requires generating detailed energy profiles along the biological surface contacting with an aqueous substance to determine the microscopic behavior at the solid–liquid interface. Considering that the charges of most atoms in biological molecules are lower than 0.36 e (67.1% of all residue atoms listed in the OPLS-AA force fields49), our findings take a major step in understanding protein–ligand binding50,51,52 in crowded cell environments, molecular transport through lipid membranes40, and protein folding related to internal friction.

Methods

Molecular dynamics simulation details and parameters

The periodic boundary conditions were applied in all directions. Our MD simulations were performed using a time step of 1.0 fs in an NVT ensemble at a temperature of 300 K. The solid atom with Lennard-Jones parameters εss = 0.2325 kJ/mol, σss = 3.4 Å53, and the SPC/E water model54 were used. A cutoff of 1.0 nm was used to calculate the dispersion (van der Waals) energies. The particle-mesh Ewald (PME)55 method and a real-space cutoff of 10 Å were used to treat long-range electrostatic interactions. The size of the simulation box is x = 6.395 nm, y = 6.816 nm and z = 21 nm. The integration time step in a simulation was 1 fs. All MD simulations were carried out using the Gromacs 4.556 software Package. We performed two series of simulations to study the contact angles and the surface frictions coefficients. The simulations to obtain the contact angles consists 900 water molecules while the simulations to obtain surface frictions coefficients consists 5103 water molecules with the thickness of water film as 4 nm. The simulation time was 80 ns for each system, and the last 2 ns data were collected for analysis.

Experimental measurement of the friction force and contact angle on HOPG or MoS2

In an environmental chamber (Shanghai Espec Environmental Equipment Corporation), a Multimode-8 AFM with Nanoscope V controller and J scanner (Bruker, Santa Barbara, CA, USA) was used in contact mode for all the measurement of the friction force. The nominal spring constant, thickness, tip height, cantilever length, and cantilever width of AFM cantilevers (XSC11 Al/BS, MikroMasch, Estonia) are 42 N/m, 2.7 μm, 15 μm, 100 μm, and 50 μm, respectively. For engaging the AFM tip, the “Deflection setpoint” was set 0.5 V, and the “VERT”, “HORZ”, and “SUM” on the AFM base kept 0.50 ± 0.01, 0.00 ± 0.02, and 3.73, respectively. After tip engaging, the “Deflection setpoint” was increased to 0.7 V to increase the loading force on the substrate through the AFM tip. Through this kind of operation process, we believe the loading force is fixed for all the experiments. By rubbing the AFM tip on the substrate at a scan angle of 90° (i.e. orthogonal to the long axis of the cantilever, Fig. 1c)57, the height image and friction signal images in both the trace and retrace directions were collected simultaneously at a controlled relative humidity ranging from 10–90%.

After subtracting the retrace frictional image from the simultaneously collected trace image, an image of the friction hysteresis at a given sample area can be obtained, which is considered to be twice of the friction force exerted at that point58 and can be exported as an ASCII file by its built-in software for statistics. To exclude the noise in the experiments, only the friction forces with the “discrete frequency” larger than 200 were adopted to calculate their averages and standard deviations. The friction force (Vlateral) takes mV as unit.

All contact angles were measured by an Attension Theta optical goniometer (Biolin Scientific AB, Sweden). A HOPG or MoS2 sheet freshly cleaved with a Scotch tape was adopted as the substrate and placed onto the level sample stage between the light source and the camera of the goniometer. A drop (about 4 µl) of pure water (18.2 MΩ cm) was injected onto the substrate. A side profile photograph of the sessile droplet was captured by the goniometer and analyzed with its built-in software to determine their static contact angles. The experiment for each substrate was repeated more than 10 times, and the contact angles at the left and right side of the droplet were averaged together.

Data availability

The data supporting the findings of this study are available within the article and its Supplementary Information files, or from the corresponding authors on reasonable request.

References

Raviv, U. & Klein, J. Fluidity of bound hydration layers. Science 297, 1540–1543 (2002).

Niguès, A., Siria, A., Vincent, P., Poncharal, P. & Bocquet, L. Ultrahigh interlayer friction in multiwalled boron nitride nanotubes. Nat. Mater. 13, 688 (2014).

Zhang, X., Zhu, Y. & Granick, S. Hydrophobicity at a Janus. Interface Sci. 295, 663–666 (2002).

Ma, M. et al. Water transport inside carbon nanotubes mediated by phonon-induced oscillating friction. Nat. Nano. 10, 692 (2015).

Leng, Y. & Cummings, P. T. Fluidity of hydration layers nanoconfined between mica surfaces. Phys. Rev. Lett. 94, 026101 (2005).

Tocci, G., Joly, L. & Michaelides, A. Friction of water on graphene and hexagonal boron nitride from ab initio methods: very different slippage despite very similar interface structures. Nano Lett. 14, 6872–6877 (2014).

Briscoe, W. H. et al. Boundary lubrication under water. Nature 444, 191–194 (2006).

Wang, C., Wen, B., Tu, Y., Wan, R. & Fang, H. Friction reduction at a superhydrophilic surface: role of ordered water. J. Phys. Chem. C. 119, 11679–11684 (2015).

Tang, Y., Zhang, X., Choi, P., Liu, Q. & Xu, Z. Probing single-molecule adhesion of a stimuli responsive oligo(ethylene glycol) methacrylate copolymer on a molecularly smooth hydrophobic MoS2 basal plane surface. Langmuir 33, 10429–10438 (2017).

Ho, T. A., Papavassiliou, D. V., Lee, L. L. & Striolo, A. Liquid water can slip on a hydrophilic surface. Proc. Natl Acad. Sci. USA 108, 16170 (2011).

Wan, R., Li, J., Lu, H. & Fang, H. Controllable water channel gating of nanometer dimensions. J. Am. Chem. Soc. 127, 7166–7170 (2005).

Cheng, M. et al. A route toward digital manipulation of water nanodroplets on surfaces. ACS Nano 8, 3955–3960 (2014).

Falk, K., Sedlmeier, F., Joly, L., Netz, R. R. & Bocquet, L. Molecular origin of fast water transport in carbon nanotube membranes: superlubricity versus curvature dependent friction. Nano Lett. 10, 4067–4073 (2010).

Secchi, E. et al. Massive radius-dependent flow slippage in carbon nanotubes. Nature 537, 210–213 (2016).

Chen, L. et al. Ion sieving in graphene oxide membranes via cationic control of interlayer spacing. Nature 550, 380 (2017).

Wang, Y., Qin, Z., Buehler, M. J. & Xu, Z. Intercalated water layers promote thermal dissipation at bio–nano interfaces. Nat. Commun. 7, 12854 (2016).

Vuković, L., Vokac, E. & Král, P. Molecular friction-induced electroosmotic phenomena in thin neutral nanotubes. J. Phys. Chem. Lett. 5, 2131–2137 (2014).

Xu, F., Song, Y., Wei, M. & Wang, Y. Water flow through interlayer channels of two-dimensional materials with various hydrophilicities. J. Phys. Chem. C. 122, 15772–15779 (2018).

Xu, F. et al. How pore hydrophilicity influences water permeability? Research 2019, 1–10 (2019).

Erbaş, A., Horinek, D. & Netz, R. R. Viscous friction of hydrogen-bonded matter. J. Am. Chem. Soc. 134, 623–630 (2011).

Bormuth, V., Varga, V., Howard, J. & Schäffer, E. Protein friction limits diffusive and directed movements of kinesin motors on microtubules. Science 325, 870–873 (2009).

Schulz, J. C. F., Schmidt, L., Best, R. B., Dzubiella, J. & Netz, R. R. Peptide chain dynamics in light and heavy water: zooming in on internal friction. J. Am. Chem. Soc. 134, 6273–6279 (2012).

de Sancho, D., Sirur, A. & Best, R. B. Molecular origins of internal friction effects on protein-folding rates. Nat. Commun. 5, 4307 (2014).

Bonn, D., Eggers, J., Indekeu, J., Meunier, J. & Rolley, E. Wetting and spreading. Rev. Mod. Phys. 81, 739–805 (2009).

Young, T. An essay on the cohesion of fluids. Philos. Trans. R. Soc. Lond. 95, 65–87 (1805).

Erbil, H. Y., Demirel, A. L., Avci, Y. & Mert, O. Transformation of a simple plastic into a superhydrophobic surface. Science 299, 1377–1380 (2003).

Liu, K. et al. Janus effect of antifreeze proteins on ice nucleation. Proc. Natl Acad. Sci. USA 113, 14739–14744 (2016).

Rafiee, J. et al. Wetting transparency of graphene. Nat. Mater. 11, 217–222 (2012).

Shih, C.-J. et al. Breakdown in the wetting transparency of graphene. Phys. Rev. Lett. 109, 176101 (2012).

Zhu, C. et al. Characterizing hydrophobicity of amino acid side chains in a protein environment via measuring contact angle of a water nanodroplet on planar peptide network. Proc. Natl Acad. Sci. USA 113, 12946–12951 (2016).

Mayrhofer, L. et al. Fluorine-terminated diamond surfaces as dense dipole lattices: the electrostatic origin of polar hydrophobicity. J. Am. Chem. Soc. 138, 4018–4028 (2016).

Wang, C. et al. Stable liquid water droplet on a water monolayer formed at room temperature on ionic model substrates. Phys. Rev. Lett. 103, 137801 (2009).

Shi, G. et al. Molecular-scale hydrophilicity induced by solute: molecular-thick charged pancakes of aqueous salt solution on hydrophobic carbon-based surfaces. Sci. Rep. 4, 6793 (2014).

Guo, P. et al. Water-COOH composite structure with enhanced hydrophobicity formed by water molecules embedded into carboxyl-terminated self-assembled monolayers. Phys. Rev. Lett. 115, 186101 (2015).

Huang, D. M., Sendner, C., Horinek, D., Netz, R. R. & Bocquet, L. Water slippage versus contact angle: a quasiuniversal relationship. Phys. Rev. Lett. 101, 226101 (2008).

Wang, C., Qi, C., Tu, Y., Nie, X. & Liang, S. Ambient conditions disordered-ordered phase transition of two-dimensional interfacial water molecules dependent on charge dipole moment. Phys. Rev. Mater. 3, 065602 (2019).

Chaban, V. V. & Prezhdo, O. V. Nitrogen–nitrogen bonds undermine stability of N-doped graphene. J. Am. Chem. Soc. 137, 11688–11694 (2015).

Chang, J.-K. et al. Spectroscopic studies of the physical origin of environmental aging effects on doped graphene. J. Appl. Phys. 119, 235301 (2016).

Anithaa, V. S. & Vijayakumar, S. Effect of side chain edge functionalization in pristine and defected graphene-DFT study. Computational Theor. Chem. 1135, 34–47 (2018).

von Hansen, Y., Gekle, S. & Netz, R. R. Anomalous anisotropic diffusion dynamics of hydration water at lipid membranes. Phys. Rev. Lett. 111, 118103 (2013).

Schneck, E., Sedlmeier, F. & Netz, R. R. Hydration repulsion between biomembranes results from an interplay of dehydration and depolarization. Proc. Natl Acad. Sci. USA 109, 14405 (2012).

Tu, Y. et al. Destructive extraction of phospholipids from Escherichia coli membranes by graphene nanosheets. Nat. Nano. 8, 968 (2013).

Tan, P. et al. Gradual crossover from subdiffusion to normal diffusion: a many-body effect in protein surface water. Phys. Rev. Lett. 120, 248101 (2018).

Shi, G. et al. Unexpectedly enhanced solubility of aromatic amino acids and peptides in an aqueous solution of divalent transition-metal cations. Phys. Rev. Lett. 117, 238102 (2016).

Luan, B. & Zhou, R. Wettability and friction of water on a MoS2 nanosheet. Appl. Phys. Lett. 108, 131601 (2016).

Wang, C. L. et al. Critical dipole length for the wetting transition due to collective water-dipoles interactions. Sci. Rep. 2, 358 (2012).

Bocquet, L. & Charlaix, E. Nanofluidics, from bulk to interfaces. Chem. Soc. Rev. 39, 1073–1095 (2010).

Giovambattista, N., Debenedetti, P. G. & Rossky, P. J. Effect of surface polarity on water contact angle and interfacial hydration structure. J. Phys. Chem. B 111, 9581–9587 (2007).

Jorgensen, W. L., Maxwell, D. S. & Tirado-Rives, J. Development and testing of the OPLS all-atom force field on conformational energetics and properties of organic liquids. J. Am. Chem. Soc. 118, 11225–11236 (1996).

Mondal, J., Morrone, J. A. & Berne, B. J. How hydrophobic drying forces impact the kinetics of molecular recognition. Proc. Natl Acad. Sci. USA 110, 13277 (2013).

Buchli, B. et al. Kinetic response of a photoperturbed allosteric protein. Proc. Natl Acad. Sci. USA 110, 11725–11730 (2013).

Buch, I., Giorgino, T. & De Fabritiis, G. Complete reconstruction of an enzyme-inhibitor binding process by molecular dynamics simulations. Proc. Natl Acad. Sci. USA 108, 10184 (2011).

Koishi, T., Yasuoka, K., Fujikawa, S., Ebisuzaki, T. & Zeng, X. C. Coexistence and transition between Cassie and Wenzel state on pillared hydrophobic surface. Proc. Natl Acad. Sci. USA 106, 8435–8440 (2009).

Berendsen, H. J. C., Grigera, J. R. & Straatsma, T. P. The missing term in effective pair potentials. J. Phys. Chem. 91, 6269–6271 (1987).

Darden, T., York, D. & Pedersen, L. Particle mesh ewald—an N.LOG(N) method for ewald sums in large systems. J. Chem. Phys. 98, 10089–10092 (1993).

Hess, B., Kutzner, C., Van, dS. D. & Lindahl, E. GROMACS 4: algorithms for highly efficient, load-balanced, and scalable molecular simulation. J. Chem. Theory Comput. 4, 435 (2008).

Wang, H. Lateral force calibration in atomic force microscopy: minireview. Sci. Adv. Mate. 9, 56–64 (2017).

Yang, C.-W. et al. Lateral force microscopy of interfacial nanobubbles: friction reduction and novel frictional behavior. Sci. Rep. 8, 3125 (2018).

Acknowledgements

The authors thank Prof. Haiping Fang for his inspiring idea and discussions. We also thank David Deibert for improving the English of this paper. This study was supported by the National Natural Science Foundation of China (Nos. 11674345, 11675138, U1532260, U1632135, U1932123), the National Science Fund for Outstanding Young Scholars (No. 11722548), Key Research Program of Chinese Academy of Sciences (QYZDJ-SSW-SLH019), Innovative research team of high-level local universities in Shanghai, Shanghai Supercomputer Center of China, Computer Network Information Center of Chinese Academy of Sciences, and Special Program for Applied Research on Super Computation of the NSFC-Guangdong Joint Fund (the second phase).

Author information

Authors and Affiliations

Contributions

G.S., Y.T., and C.W. designed the project. C.W., X.W., C.Q., M.Q. performed theoretical computation; H.Y., G. S., and C.W. performed the experiment; C.W., G.S., Y.T., and H.Y. analyzed the data; X.W., C.Q., M.Q., N.S., and R.W. conducted some theoretical analysis; C.W., G.S., Y.T., and H.Y. co-wrote the paper. All authors discussed the results and commented on the manuscript.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this license, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Wang, C., Yang, H., Wang, X. et al. Unexpected large impact of small charges on surface frictions with similar wetting properties. Commun Chem 3, 27 (2020). https://doi.org/10.1038/s42004-020-0271-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1038/s42004-020-0271-8

This article is cited by

-

Molecular Simulations of Electrotunable Lubrication: Viscosity and Wall Slip in Aqueous Electrolytes

Tribology Letters (2021)

Comments

By submitting a comment you agree to abide by our Terms and Community Guidelines. If you find something abusive or that does not comply with our terms or guidelines please flag it as inappropriate.