Abstract

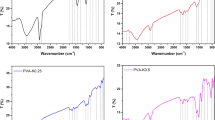

Under optimized reaction conditions, by directly using the hemostatic drugs 4-aminomethylbenzoic acid (ABA) and tranexamic acid (TA) as separate comonomers of lactic acid (LA), a series of copolymers, P(LA-co-ABA) and P(LA-co-TA), respectively, with different molar feed ratios were designed and synthesized via melt polycondensation and used as biobased polymeric sustained-release hemostatic materials. Their structure, properties and morphology were systematically investigated by Fourier transform infrared spectrometer (FTIR), proton nuclear magnetic resonance (1H NMR), gel permeation chromatography (GPC), X-ray diffraction (XRD), differential scanning calorimetery (DSC), thermogravimetric (TG), scanning electron microscopy (SEM), water contact angle and degradation tests. The degradation rate within 7 weeks can reach 77%. When the molar feed ratios of ABA and TA are 20% and 10%, respectively, the corresponding copolymers have relatively lower crystallinity and smaller water contact angle and exhibit the best coagulation performance. In addition, these powdery copolymers have good application convenience, can form a degradable protective membrane similar to a blood scab on the wound surface and continuously exert hemostatic effects to promote wound healing, as anticipated.

This is a preview of subscription content, access via your institution

Access options

Subscribe to this journal

Receive 12 print issues and online access

$259.00 per year

only $21.58 per issue

Buy this article

- Purchase on Springer Link

- Instant access to full article PDF

Prices may be subject to local taxes which are calculated during checkout

Similar content being viewed by others

References

Saporito F, Sandri G, Rossi S, Bonferoni MC, Riva F, Malavasi L, et al. Freeze dried chitosan acetate dressings with glycosaminoglycans and traxenamic acid. Carbohyd Polym. 2018;184:408–17.

Li WF, Gao FY, Kan JL, Deng J, Wang BC, Hao SL. Synthesis and fabrication of a keratin-conjugated insulin hydrogel for the enhancement of wound healing. Colloids Surf B. 2019;175:436–44.

Zhang ZY, Kuang GZ, Zong S, Liu S, Xiao HH, Chen XS, et al. Sandwich-like fibers/sponge composite combining chemotherapy and hemostasis for efficient postoperative prevention of tumor recurrence and metastasis. Adv Mater. 2018;30:1803217.

Heher P, Mühleder S, Mittermayr R, Redl H, Slezak P. Fibrin-based delivery strategies for acute and chronic wound healing. Adv Drug Deliv Rev. 2018;129:134–47.

Sundaram MN, Kaliannagounder VK, Selvaprithiviraj V, Suresh MK, Biswas R, Vasudevan AK, et al. Bioadhesive, hemostatic, and antibacterial in situ chitin-fibrin nanocomposite gel for controlling bleeding and preventing infections at mediastinum. ACS Sustain Chem Eng. 2018;6:7826–40.

Sezer UA, Kocer Z, Sahin I, Aru B, Demirel GY, Sezer S. Oxidized regenerated cellulose cross-linked gelatin microparticles for rapid and biocompatible hemostasis—a versatile cross-linking agent. Carbohyd Polym. 2018;200:624–32.

Hu Z, Lu ST, Cheng Y, Kong SZ, Li SD, Li CP, et al. Investigation of the effects of molecular parameters on the hemostatic properties of chitosan. Molecules. 2018;23:3147.

Najar MH, Minaiyan M, Taheri AJ. Preparation and in vivo evaluation of a novel gel-based wound dressing using arginine-alginate surface-modified chitosan nanofibers. Biomater Appl. 2018;32:689–701.

Tong ZR, Chen Y, Liu Y, Tong L, Chu JM, Xiao KC, et al. Preparation, characterization and properties of alginate/poly(gamma-glutamic acid) composite microparticles. Mar Drugs. 2017;15:91.

Sanandiya ND, Lee S, Rho S, Lee H, Kim IS, Hwang DS. Tunichrome-inspired pyrogallol functionalized chitosan for tissue adhesion and hemostasis. Carbohyd Polym. 2019;208:77–85.

Zhao X, Wu H, Guo BL, Dong RN, Qiu YS, Ma PX. Antibacterial anti-oxidant electroactive injectable hydrogel as self-healing wound dressing with hemostasis and adhesiveness for cutaneous wound healing. Biomaterials. 2017;122:34–47.

Zhu J, Li FX, Wang XL, Yu JY, Wu DQ. Hyaluronic acid and polyethylene glycol hybrid hydrogel encapsulating nanogel with hemostasis and sustainable antibacterial property for wound healing. ACS Appl Mater Interfaces. 2018;10:13304–16.

Lokhande G, Carrow JK, Thakur T, Xavier JR, Parani M, Bayless KJ, et al. Nanoengineered injectable hydrogels for wound healing application. Acta Biomater. 2018;70:35–47.

Catanzano O, D’Esposito V, Formisano P, Boateng JS, Quaglia F. Composite alginate-hyaluronan sponges for the delivery of tranexamic acid in postextractive alveolar wounds. J Pharm Sci. 2018;107:654–61.

Jhiang J-S, Wu T-H, Chou C-J, Chang Y, Huang C-J. Gel-like ionic complexes for antimicrobial, hemostatic and adhesive properties. J Mater Chem B. 2019;7:2878–87.

Chen L, Cheng H-H, Xiong J, Zhu Y-T, Zhang H-P, Xiong X, et al. Improved mechanical properties of poly(butylene succinate) membrane by co-electrospinning with gelatin. Chin J Polym Sci. 2018;36:1063–9.

Wang YF, Yin ML, Li ZG, Liu Y, Ren XH, Huang T-S. Preparation of antimicrobial and hemostatic cotton with modified mesoporous particles for biomedical applications. Colloids Surf B. 2018;165:199–206.

Huang H, Liu HH, Zhou H, Liang ZL, Song DD, Zhang Y, et al. Drug-release system of microchannel transport used in minimally invasive surgery for hemostasis. Drug Des Dev Ther. 2019;13:881–96.

Zhu YQ, Romain C, Williams CK. Sustainable polymers from renewable resources. Nature. 2016;540:354–62.

Hador R, Botta A, Venditto V, Lipstman S, Goldberg I, Kol M. The dual-stereocontrol mechanism: heteroselective polymerization of rac-lactide and syndioselective polymerization of meso-lactide by chiral aluminum salan catalysts. Angew Chem Int Ed. 2019;58:14679–85.

Qi M, Dong Q, Wang DW, Byers JA. Electrochemically switchable ring-opening polymerization of lactide and cyclohexene oxide. J Am Chem Soc. 2018;140:5686–90.

Marin P, Tschan MJ-L, Isnard F, Robert C, Haquette P, Trivelli X, et al. Polymerization of rac-lactide using achiral iron complexes: access to thermally stable stereocomplexes. Angew Chem Int Ed. 2019;58:12585–9.

Ladelta V, Zapsas G, Abou-hamad E, Gnanou Y, Hadjichristidis N. Tetracrystalline tetrablock quarterpolymers: four different crystallites under the same roof. Angew Chem Int Ed. 2019;58:16267–74.

He YX, Eloi J-C, Harniman RL, Richardson RM, Whittell GR, Mathers RT, et al. Uniform biodegradable fiber-like micelles and block comicelles via “living” crystallization-driven self-assembly of poly(L-lactide) block copolymers: the importance of reducing unimer self-nucleation via hydrogen bond disruption. J Am Chem Soc. 2019;141:19088–98.

Xiong ZQ, Zhang Y, Du XY, Song PA, Fang ZP. Green and scalable fabrication of core-shell biobased flame retardants for reducing flammability of polylactic acid. ACS Sustain Chem Eng. 2019;7:8954–63.

Sun JH, Li L, Li J. Effects of furan-phosphamide derivative on flame retardancy and crystallization behaviors of poly(lactic acid). Chem Eng J. 2019;369:150–60.

Kim YJ, Kim JS, Lee SY, Mahajan RL, Kim YT. Exploration of hybrid nanocarbon composite with polylactic acid for packaging applications. Int J Biol Sci. 2020;144:135–42.

Yang FH, Niu XF, Gu XN, Xu CP, Wang W, Fan YB. Biodegradable magnesium-incorporated poly(L-lactic acid) micro-spheres for manipulation of drug release and alleviation of inflammatory response. ACS Appl Mater Interfaces. 2019;11:23546–57.

Nofar M, Sacligil D, Carreau PJ, Kamal MR, Heuzey MC. Poly (lactic acid) blends: processing, properties and applications. Int J Biol Macromol. 2019;125:307–60.

Munim SA, Raza ZA. Poly(lactic acid) based hydrogels: formation, characteristics and biomedical applications. J Porous Mater. 2019;26:881–901.

Kang B-K, Kim MM, Jun DW, Park J, Jeong J, Sohn JH, et al. Stem cell treatment on acute liver failure model using semipermeable poly lactic-co-glycolic acid membrane pouch. J Hepatol. 2019;70:E422.

Shin HM, Ju Y, Kim G, Lee JW, Seo MW, Sim JH, et al. Recyclable cytokines on short and injectable polylactic acid fibers for enhancing T-cell function. Adv Funct Mater. 2019;29:1808361.

Zhang JF, Chen GJ, Bhat GS, Azari H, Pen HL. Electret characteristics of melt-blown polylactic acid fabrics for air filtration application. J Appl Polym Sci. 2020;137:48309.

Luo S-H, Wu Y-C, Cao L, Wang Q-F, Chen S-X, Hao Z-F, et al. One-pot preparation of polylactic acid-ibuprofen conjugates and their performance characterization. Polym Chem. 2017;8:7009–16.

Luo S-H, Wu Y-C, Cao L, Lin J-Y, Gao J, Chen S-X, et al. Direct metal-free preparation of functionalizable polylactic acid-ethisterone conjugates in a one-pot approach. Macromol Chem Phys. 2019;220:1800475.

Lu DD, Duan PX, Liu T, Li J, Li TE, Lei ZQ. Synthesis and characterization of biodegradable linear-hyperbranched barbell-like poly(ethylene glycol)-supported poly(lactic-ran-glycolic acid) copolymers through direct polycondensation. Polym Int. 2014;63:244–51.

Shi DJ, Hua JT, Zhang L, Chen MQ. Synthesis of bio-based poly(lactic acid-co-10-hydroxy decanoate) copolymers with high thermal stability and ductility. Polymers. 2015;7:468–83.

Li XY, Li Y-C, Chen MJ, Shi QS, Sun RC, Wang XY. Chitosan/rectorite nanocomposite with injectable functionality for skin hemostasis. J Mater Chem B. 2018;6:6544–9.

Tsuji H, Kikkawa K, Arakawa Y. Cocrystallization of monomer units of biobased and biodegradable poly(L-lactic acid-co-glycolic acid) random copolymers. Polym J. 2018;50:1079–88.

Takenaka M, Kimura Y, Ohara H. Molecular weight increase driven by evolution of crystal structure in the process of solid-state polycondensation of poly(L-lactic acid). Polymer. 2017;126:133–40.

Abu Ghalia M, Dahman YJ. Biodegradable poly(lactic acid)-based scaffolds: Synthesis and biomedical applications. J Polym Res. 2017;24:74.

Marques DS, Gil MH. Baptista CMSG. Improving lactic acid melt polycondensation: The role of co-catalyst. J Appl Polym Sci. 2013;128:2145–51.

Huang W, Cheng N, Qi YB, Zhang TR, Jiang W, Li H, et al. Synthesis of high molecular weight poly(L-lactic acid) and poly(D-lactic acid) with improved thermal stability via melt/solid polycondensation catalyzed by biogenic creatinine. Polymer. 2014;55:1491–6.

Ge YP, Yuan D, Luo ZL, Wang BB. Synthesis and characterization of poly(ester amide) from renewable resources through melt polycondensation. Express Polym Lett. 2014;8:50–54.

Jihen M, Slim S, Christelle D, Souhir A, Rachid EG. Random poly(lactic acid-co-β-alanine): synthesis and characterizations. J Macromol Sci A. 2015;52:1002–8.

Zhao XP, Ding Z, Zhang YJ, Wang YX, Peng SX. Preparation and crystallization kinetics of polyesteramide based on poly(l-lactic acid). e-Polymers. 2018;18:97–104.

Ye R-R, Wang Z-Y, Luo S-H, Yang L-T, Xiao X. Synthesis and characterization of the biomaterial poly(lactic acid-co-Nε-carbo-benzoyloxy-L-lysine) via direct melt copolymerization. J Appl Polym Sci. 2011;121:420–6.

Ye R-R, Wang Z-Y, Yang K, Luo S-H. Synthesis and character-ization of a novel biodegradable material, poly(lactic acid-co-tryptophane). Des Monomers Polym. 2010;13:415–26.

Wang Z-Y, Hou X-N, Mao Z-Z, Ye R-R, Mo Y-Q, Finlow DE. Synthesis and characterization of biodegradable poly(lactic acid-co-glycine) via direct melt copolymerization. Iran Polym J. 2008;17:791–8.

Zhao Y-M, Wang Z-Y, Yang F. Characterization of poly(D,L-lactic acid) synthesized by direct melt polymerization and its application in Chinese traditional medicine compound prescription microspheres. J Appl Polym Sci. 2005;97:195–200.

Xiong CD, Cheng LM, Xu RP, Deng XM. Studies on the copolymerization of D,L-lactide with poly(tetramethylene ether glyeol). Funct Polym. 1991;4:133–8.

Wang Z-Y, Zhao H-J, Wang Q-F, Ye R-R, Finlow DE. Biodegradable aliphatic/aromatic copolyesters based on terephthalic acid and poly(L-lactic acid): synthesis, characterization and hydrolytic degradation. J Appl Polym Sci. 2010;117:1405–15.

Xiong J-F, Luo S-H, Wang Q-F, Wang Z-Y, Qi J. Synthesis and characterization of a novel flame retardant, poly(lactic acid-co-3,3’-diaminobenzidine). Des Monomers Polym. 2013;16:389–97.

Perumal G, Pappuru S, Chakraborty D, Nandkumar AM, Chand DK, Doble M. Synthesis and characterization of curcumin loaded PLA-hyperbranched polyglycerol electrospun blend for wound dressing applications. Mater Sci Eng C. 2017;76:1196–204.

Hickman DA, Pawlowski CL, Sekhon UDS, Marks J, Sen Gupta A. Biomaterials and advanced technologies for hemostatic management of bleeding. Adv Mater. 2018;30:1700859.

Sara P, Nahrizul AK, Ehsan Z, Mark RT. Well-ordered mesoporous silica and bioactive glasses: Promise for improved hemostasis. Biomater Sci. 2019;7:31–50.

Zhang SH, Li JW, Chen SJ, Zhang XY, Ma JW, He JM. Oxidized cellulose-based hemostatic materials. Carbohyd Polym. 2020;230:115585.

Luo YF, Wang YL, Niu XF, Fu CH, Wang SJ. Synthesis, characterization and biodegradation of butanediamine-grafted poly(D, L-lactic acid). Eur Polym J. 2007;43:3856–64.

Bolliger D, Tanaka KA. Tranexamic acid in vascular surgery: antifibrinolytic or clot-stabilising activity. Br J Anaesth. 2020;124:4–6.

Acknowledgements

This research was supported by the Science and Technology Program of Guangzhou (No. 201607010301), the Open Fund of the Key Laboratory of Functional Molecular Engineering of Guangdong Province in SCUT (No. 2017kf01), the National Natural Science Foundation of China (20772035), and the Guangdong Provincial Science and Technology Project (No. 2017A010103016).

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s note Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary information

Rights and permissions

About this article

Cite this article

Lin, JY., Luo, SH., Chen, SH. et al. Efficient synthesis, characterization, and application of biobased scab-bionic hemostatic polymers. Polym J 52, 615–627 (2020). https://doi.org/10.1038/s41428-020-0315-z

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1038/s41428-020-0315-z

This article is cited by

-

Furanonyl amino acid derivatives as hemostatic drugs: design, synthesis and hemostasis performance

Amino Acids (2022)

-

Haemostatic materials for wound healing applications

Nature Reviews Chemistry (2021)