Abstract

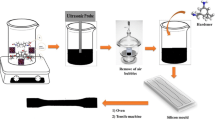

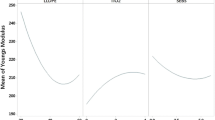

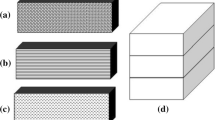

An immense technological challenge of polypropylene-based composites is in optimising the effect of multicomponent fractions on their mechanical properties. Hence the main aim of the present study is to carry out a systematic statistical approach to investigate the impact of multicomponent fractions on the mechanical properties of Polypropylene (PP)/Talc/ Polyolefin Elastomer (POE) and maleic-anhydride-grafted Polypropylene (PPMA) composites. Response Surface Methodology (RSM) based on Central Composite Design (CCD) has been implemented as the design of experiment technique. With respect to CCD and three different weight percentages of Talc (0, 15, 30 wt%), POE (0, 10, 20 wt%), and PPMA (0, 2.5, 5 wt%), 17 experiments were designed and prepared via a conventional melt blending technique. Analysis of variance (ANOVA) with diagnostic figures has been proposed to derive mathematical models to predict the mechanical properties of the utilised PP based composite. The findings showed that the concentration of POE, particularly at a lower amount, play a significant role and can predominantly affect the properties of the composites. The results also revealed that in spite of Talc and PPMA, adding of POE caused a noticeable rise in ductility and toughness of composite and a reduction in the stiffness. It was also found that all the assessed properties can be maximized simultaneously, providing the content of Talc, POE, and PPMA set to be 30%, 6.228%, and 2.514%, respectively. The findings are found to be aligned with the scanning electron microscopy micrographs and the DSC analysis data.

Similar content being viewed by others

References

Ashenai Ghasemi F, Ghasemi I, Menbari S et al (2016) Optimization of mechanical properties of polypropylene/talc/graphene composites using response surface methodology. Polym Test 53:283–292. https://doi.org/10.1016/J.POLYMERTESTING.2016.06.012

Bagheri-Kazemabad S, Fox D, Chen Y et al (2012) Morphology, rheology and mechanical properties of polypropylene/ethylene–octene copolymer/clay nanocomposites: effects of the compatibilizer. Compos Sci Technol 72:1697–1704. https://doi.org/10.1016/J.COMPSCITECH.2012.06.007

Jahani Y (2010) Dynamic rheology, mechanical performance, shrinkage, and morphology of chemically coupled talc-filled polypropylene. J Vinyl Addit Technol 16:70–77. https://doi.org/10.1002/vnl.20209

Ajorloo M, Fasihi M, Ohshima M, Taki K (2019) How are the thermal properties of polypropylene/graphene nanoplatelet composites affected by polymer chain configuration and size of nanofiller? Mater Des 181:108068. https://doi.org/10.1016/j.matdes.2019.108068

Tarashi S, Nazockdast H, Javidi Z, Mehranpour M (2019) Long-chain branch-induced interfacial interaction and its effect on morphology development in polypropylene/ethylene octene copolymer blend. J Mater Sci 54:6742–6751. https://doi.org/10.1007/s10853-019-03341-x

Mahendra IP, Wirjosentono B, Tamrin et al (2019) The influence of maleic anhydride-grafted polymers as compatibilizer on the properties of polypropylene and cyclic natural rubber blends. J Polym Res 26:26–10. https://doi.org/10.1007/s10965-019-1878-2

Ghasemi FA, Niyaraki MN, Ghasemi I, Daneshpayeh S (2019) Predicting the tensile strength and elongation at break of PP/graphene/glass fiber/EPDM nanocomposites using response surface methodology. Mech Adv Mater Struct. https://doi.org/10.1080/15376494.2019.1614702

Fasihi M, Mansouri H (2016) Effect of rubber interparticle distance distribution on toughening behavior of thermoplastic polyolefin elastomer toughened polypropylene. J Appl Polym Sci:133. https://doi.org/10.1002/app.44068

Wang J, Guo J, Li C, Yang S, Wu H, Guo S (2014) Crystallization kinetics behavior, molecular interaction, and impact-induced morphological evolution of polypropylene/poly(ethylene-co-octene) blends: insight into toughening mechanism. J Polym Res 21:618–613. https://doi.org/10.1007/s10965-014-0618-x

Poothanari MA, Xavier P, Bose S et al (2019) Compatibilising action of multiwalled carbon nanotubes in polycarbonate/polypropylene (PC/PP) blends: phase morphology, viscoelastic phase separation, rheology and percolation. J Polym Res 26. https://doi.org/10.1007/s10965-019-1833-2

Wu J-H, Chen C-W, Wu Y-T et al (2015) Mechanical properties, morphology, and crystallization behavior of polypropylene/elastomer/talc composites. Polym Compos 36:69–77. https://doi.org/10.1002/pc.22914

Bai H, Wang Y, Song B, Han L (2008) Synergistic toughening effects of nucleating agent and ethylene–octene copolymer on polypropylene. J Appl Polym Sci 108:3270–3280. https://doi.org/10.1002/app.27980

Tang W, Tang J, Yuan H, Jin R (2011) Crystallization behavior and mechanical properties of polypropylene random copolymer/poly(ethylene-octene) blends. J Appl Polym Sci 122:461–468. https://doi.org/10.1002/app.34162

Liu G, Qiu G (2013) Study on the mechanical and morphological properties of toughened polypropylene blends for automobile bumpers. Polym Bull 70:849–857. https://doi.org/10.1007/s00289-012-0880-1

Zhu L, Xu X, Ye N et al (2009) Influence of composition and phase morphology on rheological properties of polypropylene/poly(ethylene-co-octene) blends. Polym Compos 31:105–113. https://doi.org/10.1002/pc.20773

Liang J-Z (2012) Mechanical properties and morphology of polypropylene/poly(ethylene-co-octene) blends. J Polym Environ 20:872–878. https://doi.org/10.1007/s10924-012-0441-6

Hu X, Geng C, Yang G et al (2015) Synergetic effects of a matrix crystalline structure and chain mobility on the low temperature toughness of polypropylene/ethylene–octene copolymer blends. RSC Adv 5:54488–54496. https://doi.org/10.1039/C5RA09685E

Liu Y, Kontopoulou M (2006) The structure and physical properties of polypropylene and thermoplastic olefin nanocomposites containing nanosilica. Polymer (Guildf) 47:7731–7739. https://doi.org/10.1016/J.POLYMER.2006.09.014

Castillo LA, Barbosa SE, Capiati NJ (2013) Influence of talc morphology on the mechanical properties of talc filled polypropylene. J Polym Res 20:152–159. https://doi.org/10.1007/s10965-013-0152-2

Lapcik L, Jindrova P, Lapcikova B et al (2008) Effect of the talc filler content on the mechanical properties of polypropylene composites. J Appl Polym Sci 110:2742–2747. https://doi.org/10.1002/app.28797

Wang T, Liu D, Keddie JL (2007) An alternative approach to the modification of talc for the fabrication of polypropylene/talc composites. J Appl Polym Sci 106:386–393. https://doi.org/10.1002/app.26462

Nevalainen K, Auvinen S, Orell O et al (2013) Characterization of melt-compounded and masterbatch-diluted polypropylene composites filled with several fillers. Polym Compos 34:554–569. https://doi.org/10.1002/pc.22454

Sheril RV, Mariatti M, Samayamutthirian P (2014) Single and hybrid mineral fillers (talc/silica and talc/calcium carbonate)-filled polypropylene composites: effects of filler loading and ratios. J Vinyl Addit Technol 20:160–167. https://doi.org/10.1002/vnl.21347

Igarza E, Pardo SG, Abad MJ et al (2014) Structure–fracture properties relationship for polypropylene reinforced with fly ash with and without maleic anhydride functionalized isotactic polypropylene as coupling agent. Mater Des 55:85–92. https://doi.org/10.1016/J.MATDES.2013.09.055

Bouaziz A, Jaziri M, Dalmas F, Massardier V (2014) Nanocomposites of silica reinforced polypropylene: correlation between morphology and properties. Polym Eng Sci 54:2187–2196. https://doi.org/10.1002/pen.23768

Doufnoune R, Chebira F, Haddaoui N (2003) Effect of TITANATE coupling agent on the mechanical properties of calcium carbonate filled polypropylene. Int J Polym Mater 52:967–984. https://doi.org/10.1080/714975875

El-Midany AA, Ibrahim SS (2010) The effect of mineral surface nature on the mechanical properties of mineral-filled polypropylene composites. Polym Bull 64:387–399. https://doi.org/10.1007/s00289-009-0209-x

Mehrjerdi AK, Mengistu BA, Åkesson D, Skrifvars M (2014) Effects of a titanate coupling agent on the mechanical and thermo-physical properties of talc-reinforced polyethylene compounds. J Appl Polym Sci 131:n/a-n/a. https://doi.org/10.1002/app.40449

Castillo LA, Barbosa SE, Capiati NJ (2012) Influence of talc genesis and particle surface on the crystallization kinetics of polypropylene/talc composites. J Appl Polym Sci 126:1763–1772. https://doi.org/10.1002/app.36846

Pivsa-Art W, Fujii K, Nomura K et al (2016) Isothermal crystallization kinetics of talc-filled poly(lactic acid) and poly(butylene succinate) blends. J Polym Res 23. https://doi.org/10.1007/s10965-016-1045-y

Duan J, Dou Q (2013) Investigation on β-polypropylene/PP- g -MAH/surface treated talc composites. J Appl Polym Sci 130:206–221. https://doi.org/10.1002/app.39178

García-Martínez JM, Areso S, Taranco J, Collar EP (2009) Dynamic mechanical analysis of the interfacial changes in polypropylene/talc composites induced by different interfacial modifications from the reinforcement side. J Appl Polym Sci 114:551–561. https://doi.org/10.1002/app.30499

Othman NAF, Selambakkannu S, Ting TM et al (2019) Integration of phosphoric acid onto radiation grafted poly (2,3-epoxypropyl methacrylate) -PP/PE non-woven fabrics aimed copper adsorbent via response surface method. J Polym Res 26. https://doi.org/10.1007/s10965-019-1963-6

Ghasemi I, Karrabi M, Mohammadi M, Azizi H (2010) Evaluating the effect of processing conditions and organoclay content on the properties of styrene-butadiene rubber/organoclay nanocomposites by response surface methodology. Express Polym Lett 4:62–70. https://doi.org/10.3144/expresspolymlett.2010.11

Taghizadegan S (2006) Six sigma master Black Belt level case study. Essentials Lean Six Sigma:205–223. https://doi.org/10.1016/B978-012370502-0/50012-6

Yaghoobi H, Fereidoon A (2018) An experimental investigation and optimization on the impact strength of kenaf fiber biocomposite: application of response surface methodology. Polym Bull 75:3283–3309. https://doi.org/10.1007/s00289-017-2212-y

ANOVA Test: Definition, types, Examples - Statistics How To https://www.statisticshowto.datasciencecentral.com/probability-and-statistics/hypothesis-testing/anova/. Accessed 28 May 2019

Ashenai Ghasemi F, Daneshpayeh S, Ghasemi I (2017) Multi-response optimization of impact strength and elongation at break of nanocomposites based on polypropylene/polyethylene binary polymer matrix in the presence of titanium dioxide nanofiller. J Elastomers Plast 49:633–649. https://doi.org/10.1177/0095244316681834

Hosseinnezhad M, Shadman A, Saeb MR, Mohammadi Y (2017) A new direction in design and manufacture of co-sensitized dye solar cells: toward concurrent optimization of power conversion efficiency and durability. Opto-Electronics Rev 25:229–237. https://doi.org/10.1016/J.OPELRE.2017.06.003

Wong KW-Y, Truss RW (1994) Effect of flyash content and coupling agent on the mechanical properties of flyash-filled polypropylene. Compos Sci Technol 52:361–368. https://doi.org/10.1016/0266-3538(94)90170-8

Ataeefard M, Shadman A, Saeb MR, Mohammadi Y (2016) A hybrid mathematical model for controlling particle size, particle size distribution, and color properties of toner particles. Appl Phys A Mater Sci Process 122:726–714. https://doi.org/10.1007/s00339-016-0242-1

Daneshpayeh S, Ashenai Ghasemi F, Ghasemi I, Ayaz M (2016) Predicting of mechanical properties of PP/LLDPE/TiO2 nano-composites by response surface methodology. Compos Part B Eng 84:109–120. https://doi.org/10.1016/J.COMPOSITESB.2015.08.075

Altay L, Atagur M, Sever K et al (2019) Synergistic effects of graphene nanoplatelets in thermally conductive synthetic graphite filled polypropylene composite. Polym Compos 40:277–287. https://doi.org/10.1002/pc.24643

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ajorloo, M., Ghodrat, M., Moghbeli, M.R. et al. A statistical approach to investigate the effects of multicomponent fractions on the mechanical properties of PP/PPMA/Talc/POE composites. J Polym Res 27, 65 (2020). https://doi.org/10.1007/s10965-020-2042-8

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s10965-020-2042-8