Abstract

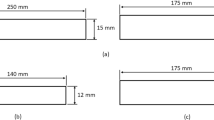

In this paper, crashworthiness of thermoplastic woven fabric reinforced composite tubes were investigated. Thermoplastic composite tubes with various length (40 mm and 80 mm) and fiber yarn orientation with respective to lengthwise (0 °/90 °, 15 °/75 °, 30 °/60 ° and 45 °/45 °) were manufactured by pultrusion and welding from home-made woven glass fabric/PP prepreg sheets. Quasi-static axial compressive tests of the composite tubes were performed under various temperatures (298 K, 358 K, 398 K and 453 K). Three crushing modes were observed: progressive folding, splaying and weld seam cracking. The influence of fiber orientation, tube length-diameter ratio and testing temperature on the peak load, mean load, specific energy absorption and crush efficiency were investigated. The results show that the peak load is controlled by fiber orientation and testing temperature. The mean force, specific energy absorption and crush efficiency are related to the three mentioned factors. Both fiber orientation and testing temperature have obviously influence on crushing modes of thermoplastic composite tubes. Length-to-diameter ratio also plays a role in crushing modes when the testing temperature is higher than the melting point of the resin.

Similar content being viewed by others

References

A. O. Ayhan, K. Genel, and S. Ekş, Thin Wall. Struct., 51, 1 (2012).

X. Xue, J. Liao, G. Vincze, and A. B. Pereira, Int. J. Mater. Form., 11, 311 (2018).

A. G. Mamalis, M. Robinson, D. E. Manolakos, G. A. Demosthenous, M. B. Ioannidis, and J. Carruthers, Compos. Struct., 37, 109 (1997).

T. Wierzbicki and W. Abramowicz, J. Appl. Mech., 50, 727 (1983).

E. Morris, A. G. Olabi, and M. S. J. Hashmi, Thin Wall. Struct., 44, 872 (2006).

H. Böhm, D. Weck, A. Hornig, A. Langkamp, F. Adam, and M. Gude, Adv. Eng. Mater., 18, 437 (2016).

K. Liu, B. Zhang, X. Xu, and J. Ye, Int. J. Mater. Form, 12, 97 (2019).

A. M. N. Azammi, S. M. Sapuan, M. R. Ishak, and M. T. H. Sultan, Fiber. Polym., 19, 446 (2018).

H. Ning, S. Pillay, K. B. Thattaiparthasarathy, and U. K. Vaidya, Compos. Struct., 168, 792 (2017).

H. Zarei, M. Kröger, and H. Albertsen, Compos. Struct., 85, 245 (2008).

A. G. Mamalis, Y. B. Yuan, and G. L. Viegelahn, Int. J. Vehicle Des., 13, 562 (1992).

C. Priem, R. Othman, P. Rozycki, and D. Guillon, Compos. Struct., 116, 814 (2014).

S. Boria, A. Scattina, and G. Belingardi, Compos. Struct., 140, 21 (2016).

N. C. Correia, F. Robitaille, A. C. Long, C. D. Rudd, P. Šimáček, and S. G. Advani, Compos. Part A-Appl. Sci. Manuf., 36, 1645 (2005).

B. V. Voorn, H. H. G. Smit, R. J. Sinke, and B. D. Klerk, Compos. Part A-Appl. Sci. Manuf., 32, 1271 (2001).

K. V. D. Velde and P. Kiekens, Compos. Struct., 54, 355 (2001).

A. H. Miller, N. Dodds, J. M. Hale, and A. G. Gibson, Compos. Part A-Appl. Sci. Manuf., 29, 773 (1998).

J. Zhang and S. Qi, Polym. Compos., 35, 381 (2014).

M. S. Huda, L. T. Drzal, A. K. Mohanty, and M. Misra, Compos. Sci. Technol., 68, 424 (2008).

I. F. Villegas and H. E. N. Bersee, Adv. Polym. Tech., 29, 112 (2010).

B. Frank, W. Guntram, and E. Dietmar, Adv. Eng. Mater., 11, 35 (2010).

G. Palardy and I. F. Villegas, Compos. Interface, 24, 203 (2017).

C. H. Chiu, K. H. Tsai, and W. J. Huang, Compos. Sci. Technol., 59, 1713 (1999).

L. J. Gui, P. Zhang, and Z. J. Fan, Int. J. Crashworthines., 14, 1 (2009).

X. Xiao, M. E. Botkin, and N. L. Johnson, Thin Wall. Struct., 47, 740 (2015).

N. D. Flesher, F. K. Chang, and N. R. Janapala, J. Compos. Mater., 45, 853 (2011).

N. D. Flesher, F. K. Chang, N. R. Janapala, and J. M. Starbuck, J. Compos. Mater., 45, 867 (2011).

M. Okano, A. Nakai, and H. Hamada, Int. J. Crashworthines., 10, 287 (2005).

Y. Wang, J. Feng, J. Wu, and D. Hu, Compos. Struct., 153, 356 (2016).

J. Xu, Y. Ma, Q. Zhang, T. Sugahara, Y. Yang, and H. Hamada, Compos. Struct., 139, 130 (2016).

Acknowledgements

The support from the Open Project of Shanghai Key Laboratory of Spacecraft Mechanism (Grant No.: SCCA5000003) is gratefully acknowledged.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Liu, M., Yan, B., Peng, X. et al. Crashworthiness of Thermoplastic Woven Glass Fabric Reinforced Composite Tubes Manufactured by Pultrusion. Fibers Polym 21, 416–427 (2020). https://doi.org/10.1007/s12221-020-9440-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9440-8