Abstract

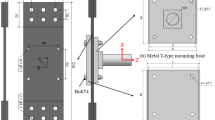

This work designed a T-shaped hook-connected structure composed of a bottom plate made of 2.5D woven composites and a T-shaped plate made of TC4 alloy. In order to explore to its bending and tensile properties, the corresponding experiments were designed and performed. Then, based on the progressive damage model and an improved Hashin’s failure criteria, numeral calculations were conducted in ANSYS to study its bending and tensile damage propagations. Compared with experimental results, the maximum error is less than 20 %, and the damage modes are similar, which proves the rationality of numerical calculation. In addition, both the experimental and simulation results show that the fatal damage both occurs at the constrained plate of the bottom plate whether in bending or tensile processes. Specifically, the fatal failure occurs at the installed edges in bending process or at the sides of groove-middle to groove-edge in tensile process. This work provides a design reference for typical T-shaped hook-connected composite structure, especially the connector of blade and casing, which appear in engineering and has good engineering application value.

Similar content being viewed by others

References

G. E. Kirk, “Composite Materials for Future Aeroengines. In: Gas Turbine and Aeroengine Congress and Exposition” ASME-89-GT-313, Toronto, Ontario, Canada, 1989.

J. Song, W. D. Wen, H. T. Cui, H. J. Zhang, and Y. Xu, Appl. Compos. Mater., 23, 45 (2016).

J. Song, W. D. Wen, H. T. Cui, H. J. Zhang, and Y. Xu, Appl. Compos. Mater., 23, 29 (2016).

M. Muthukumar, J. Prasath, S. Sathish, G. Ravikumar, Y. M. Desai, and N. K. Naik, J. Reinf. Plast. Compos., 36 1263 (2017).

M. Umair, S. T. A. Hamdani, M. A. Asghar, T. Hussain, M. Karahan, Y. Nawab, and M. Ali, J. Reinf. Plast. Compos.37, 429 (2018).

W. B. Hou, X. Z. Xu, H. F. Wang, and L. Y. Tong, J. Reinf. Plast. Compos., 37, 808 (2018).

J. S. Jiang, C. X. Liao, and L. Q. Zhou, J. Reinf. Plast. Compos., 31, 351 (2012).

S. A. Tabatabaei and S. V. Lomov, Comput. Struct., 152, 142 (2015).

Z. X. Lu, Y. Zhou, Z. Y. Yang, and Q. Liu, Comp. Mater. Sci., 79, 485 (2013).

H. J. Zhang, J. H. Guo, W. D. Wen, H. T. Cui, S. He, and Y. Xu, Compos. Struct., 206, 155 (2018).

H. J. Zhang, J. H. Guo, W. D. Wen, H. T. Cui, and S. He, Text. Res. J., 89, 4046 (2019).

A. P. Mouritz, J. Compos. Mater., 48, 2905 (2014).

F. Romano, F. Di Caprio, B. Auriemma, and U. Mercurio, Eng. Fail. Anal., 56, 116 (2015).

Y. W. Ouyang, B. Z. Sun, and B. H. Gu, J. Compos. Mater., 52, 1139 (2018).

F. Hélénon, M. R. Wisnom, S. R. Hallett, and R. S. Trask, Compos. Part A-Appl. Sci. Manuf., 54, 182 (2013).

H. J. Zhang, W. D. Wen, and H. T. Cui, Compos. Part BEng.43, 3310 (2012).

Z. Hashin, J. Appl. Mech., 2, 329 (1980).

Z. Hashin, Compos. Sci. Technol., 23, 1 (1985).

Acknowledgments

This work has been supported by National Science and Technology Major Project (2017-IV-0007-0044).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, H., Guo, J., Wen, W. et al. Mechanical Behaviors on T-shaped Hook-connected Structure Made of 2.5D Woven Composites and TC4 Alloy. Fibers Polym 21, 407–415 (2020). https://doi.org/10.1007/s12221-020-9303-3

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12221-020-9303-3