Abstract

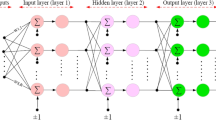

A domestic cookie baking process was modeled using nonlinear forward and inverse models to predict surface temperature, moisture content and browning index that describe the baking quality of the end product. The baking processes were carried out at different oven temperatures (160, 180, 200 °C) and the changes in surface temperature, moisture content and browning index were determined to construct the identification models namely nonlinear polynomial models (PLN) and nonlinear artificial-neural network (ANN) model. The parameters of the artificial models were optimized using least-squares estimation and Levenberg-Marquardt optimization, respectively. The predicted baking characteristics in both forward and inverse phases were in good agreement with the measured ones even for the browning index which was difficult to model because of the its nonminimum-phase dynamics. The application results indicated that the developed intelligient models were very accurate, having low root mean-squared errors, the ANN model approximated the desired values better than the PLN models for all the state variables. Thus, the designed ANN models are applicable for the automatized industrial and domestic oven designs of the future.

Similar content being viewed by others

References

Özilgen M, Heil J (1994) Mathematical modeling of transient heat and mass transport in a baking biscuit. Journal of food processing and preservation 18(2):133–148

Ahrné L, Andersson C-G, Floberg P, Rosén J, Lingnert H (2007) Effect of crust temperature and water content on acrylamide formation during baking of white bread: steam and falling temperature baking. LWT-Food Scie Technol 40(10):1708–1715

Ureta MM, Olivera DF, Salvadori VO (2014) Quality attributes of muffins: Effect of baking operative conditions. Food and Bioprocess Technology 7(2):463–470

Broyart B, Trystram G, Duquenoy A (1998) Predicting colour kinetics during cracker baking. J Food Eng 35(3):351–368

Sandra Mundt and Bronislaw L Wedzicha. A kinetic model for browning in the baking of biscuits: effects of water activity and temperature. LWT-Food Sci Technol, 40(6):1078–1082, 2007

Isleroglu H, Kemerli T, Sakin-Yilmazer M, Guven G, Ozdestan O, Uren A, Kaymak-Ertekin F (2012) Effect of steam baking on acrylamide formation and browning kinetics of cookies. J Food Sci 77(10):E257–E263

Broyart B, Trystram G (2003) Modelling of heat and mass transfer phenomena and quality changes during continuous biscuit baking using both deductive and inductive (neural network) modelling principles. Food Bioprod Process 81(4):316–326

Hogervorst JGF, Van Den Brandt PA, Godschalk RWL, van Schooten F-J, Schouten LJ (2016) The influence of single nucleotide polymorphisms on the association between dietary acrylamide intake and endometrial cancer risk. Scie Rep 6:34902

Fennema OW (1993) Quimica de los alimentos. Editorial Acribia, S. A

Chen CR, Ramaswamy HS, Marcotte M (2007) Neural network applications in heat and mass transfer operations in food processing. WIT Trans State-of-the-art in Sci Eng 13:39–59

Shahpour Jahedi Rad, Mohammad Kaveh, Vali Rasooli Sharabiani, and Ebrahim Taghinezhad. Fuzzy logic, artificial neural network and mathematical model for prediction of white mulberry drying kinetics. Heat Mass Transf, 54(11):3361–3374, Nov 2018

Alam MA, Saha CK, Alam MM, Ashraf MA, Bala BK, Harvey J Neural network modeling of drying of rice in bau-str dryer. Heat Mass Transf 54(11):3297–3305 Nov 2018

Çebi A, Akdoğan E, Celen A, Dalkilic AS (Feb 2017) Prediction of friction factor of pure water flowing inside vertical smooth and microfin tubes by using artificial neural networks. Heat Mass Transf 53(2):673–685

Ljung L (1999) System identification theory for the user. Prentice Hall PTR

Isleroglu H, Beyhan S (2018) Intelligent models based nonlinear modeling for infrared drying of mahaleb puree. J Food Process Eng 41(8):e12912

Beyhan S, Kavaklioglu K (2015) Comprehensive modeling of u-tube steam generators using extreme learning machines. IEEE Trans Nucl Sci 62(5):2245–2254

Banooni S, Hosseinalipour SM, Mujumdar AS, Taherkhani P, Bahiraei M (2009) Baking of flat bread in an impingement oven: modeling and optimization. Dry Technol 27(1):103–112

Sablani SS, Ramaswamy HS, Sreekanth S, Prasher SO (1997) Neural network modeling of heat transfer to liquid particle mixtures in cans subjected to end-over-end processing. Food Res Int 30(2):105–116

Hussain MA, Shafiur M (2002) Rahman, and CW Ng. Prediction of pores formation (porosity) in foods during drying: generic models by the use of hybrid neural network. J Food Eng 51(3):239–248

Popescu O, Popescu DC, Wilder J, Karwe MV (2001) A new approach to modeling and control of a food extrusion process using artificial neural network and an expert system. J Food Process Eng 24(1):17–36

Chen CR, Ramaswamy HS, Prasher SO (2002) Dynamic modeling of retort processing using neural networks. Journal of Food Processing and Preservation 26(2):91–111

Vasquez N, Magin C, Oblitas J, Chuquizuta T, Avila-George H, Castro W (2018) Comparison between artificial neural network and partial least squares regression models for hardness modeling during the ripening process of swiss-type cheese using spectral profiles. J Food Eng 219:8–15

Hernández JA (2009) Optimum operating conditions for heat and mass transfer in food stuffs drying by means of neural network inverse. Food Control 20(4):435–438

Liu X, Chen X, Wu W, Peng G (2007) A neural network for predicting moisture content of grain drying process using genetic algorithm. Food Control 18(8):928–933

Dadalı G (2007) Dilek Kılıç Apar, and Belma Özbek. Color change kinetics of okra undergoing microwave drying. Dry Technol 25(5):925–936

Scales LE (1985) Introduction to non-linear optimization. Springer-Verlag New York, Inc.

Purlis E, Salvadori VO (2009) Bread baking as a moving boundary problem. part 1: mathematical modelling. Journal of Food Engineering 91(3):428–433

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher’s note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Isleroglu, H., Beyhan, S. Prediction of baking quality using machine learning based intelligent models. Heat Mass Transfer 56, 2045–2055 (2020). https://doi.org/10.1007/s00231-020-02837-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s00231-020-02837-6