Abstract

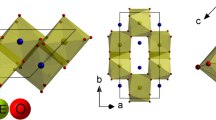

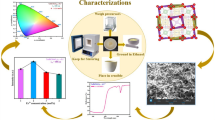

A series of intense red-emission phosphors, Y3Mg2Nb3O14:Eu3+, with higher color purity were prepared via the conventional high-temperature ceramic route. The influence of Mg2+ ion incorporation in the highly symmetrical YNbO4 lattice on the luminescence properties was studied using powder x-ray diffraction, scanning electron microscopy with energy dispersive spectrometry, UV–visible absorption spectroscopy, and photoluminescence measurements. The developed phosphors crystallize into a monoclinic fergusonite-type structure with a C2/c space group even with the addition of Mg into the system. These phosphors display intense, sharp, red emission with a maximum at 613 nm under near-UV excitation. The photoluminescence studies suggest that Mg addition perturbs the A site network forming cation pairs of Eu3+-Y3+, Eu3+-Mg2+, and Eu3+-Eu3+ connected with O2− ions. The preferential occupation of cations in the A site network by the incorporation of Mg2+ ions in the YNbO4 host lattice induces Eu3+-Eu3+ separation and results in intense, sharp, red emission due to increased radiative probabilities. Moreover, the color purity of the Y3−xMg2Nb3O14:xEu3+ phosphor could achieve 92.4% that is attributed to the narrow full width at half maximum (FWHM ∼ 4 nm) of the red emission peaking at 613 nm. More importantly, the luminescence intensity of the developed phosphor is 9.4 times greater than that of the Philip’s red phosphor under near-UV excitation. Because of the intriguing red luminescence, phosphors exhibit Commission Internationale de l’Elcairage color coordinates (0.63, 0.35) close to the National Television System Committee standards, low correlated color temperature values for warm white lighting, and greater color purity (92.4%) for improving the color rendering index, which makes them a potential candidate for use in the fabrication of white light-emitting diodes.

Similar content being viewed by others

References

P. Pust, P.J. Schmidt, and W. Schnick, Nat. Mater. 14, 454 (2015).

C.C. Lin, A. Meijerink, and R.S. Liu, J. Phys. Chem. Lett. 7, 495 (2016).

C.W. Yeh, W.T. Chen, R.S. Liu, S.F. Hu, H.S. Sheu, J.M. Chen, and H.T. Hintzen, J. Am. Chem. Soc. 134, 14108 (2012).

S.S. Wang, W.T. Chen, Y. Li, J. Wang, H.S. Sheu, and R.S. Liu, J. Am. Chem. Soc. 135, 12504 (2013).

R.J. Xie, N. Hirosaki, Y. Li, and T. Takeda, Materials 3, 3777 (2010).

J. Meyer and F. Tappe, Adv. Opt. Mater. 3, 424 (2015).

G. Li, Y. Tian, Y. Zhao, and J. Lin, Chem. Soc. Rev. 44, 8688 (2015).

X. Huang, Nat. Photon. 8, 748 (2014).

P. Pust, V. Weiler, C. Hecht, A. Tücks, A.S. Wochnik, A.-K. Hen, D. Wiechert, C. Scheu, P.J. Schmidt, and W. Schnick, Nat. Mater. 13, 891 (2014).

T. Takeda, N. Hirosaki, S. Funahashi, and R.J. Xie, Mater. Discov. 1, 29 (2015).

J. Wan, Q. Liu, G. Liu, Z. Zhou, and R.J. Xie, J. Mater. Chem. C 5, 6061 (2017).

G.E. Yiyao, T. Zhaobo, C. Ying, S. Siyuan, Z. Jie, and X. Zhipeng, J. Rare Earths 35, 430 (2017).

G. Li, Y. Zhao, J. Xu, Z. Mao, J. Chen, and D. Wang, Mater. Chem. Phys. 201, 1 (2017).

H. Yuan, Z. Huang, F. Chen, Q. Shen, and L. Zhang, J. Alloys Compd. 720, 521 (2017).

H. Jia, L. Cao, Y. Wei, H. Wang, H. Xiao, G. Li, and J. Lin, J. Alloys Compd. 738, 307 (2018).

T. Senden, E.J. van Harten, and A. Meijerink, J. Lumin. 194, 131 (2018).

S. Adachi, J. Lumin. 197, 119 (2018).

Y. Li, S. Qi, P. Li, and Z. Wang, RSC Adv. 7, 38318 (2017).

L.Y. Wang, E.H. Song, Y.Y. Zhou, T.T. Deng, S. Ye, and Q.Y. Zhang, J. Mater. Chem. C. 5, 7253 (2017).

H. Cheng, Y. Song, G. Liu, D. Li, X. Dong, J. Wang, and W. Yu, RSC Adv. 7, 45834 (2017).

A. Katelnikovas, J. Plewa, S. Sakirzanovas, D. Dutczak, D. Enseling, F. Baur, H. Winkler, A. Kareiva, and T. Jüstel, J. Mater Chem. 22, 22126 (2012).

P.A. Tanner, Chem. Soc. Rev. 42, 5090 (2013).

G. Blasse, Philips Res. Rep. 24, 131 (1969).

S.W. Choi, G. Anoop, D.W. Suh, K.P. Kim, H.L. Lee, and J.S. Yoo, J. Rare Earths 30, 205 (2012).

K. Fulle, C.D. McMillen, L.D. Sanjeewa, and J.W. Kolis, Cryst. Growth Des. 16, 4910 (2016).

G. Blasse and A. Bril, J. Lumin. 3, 109 (1970).

G. Blasse, J. Lumin. 14, 231 (1976).

X. Liu, Y. Lu, C. Chen, S. Luo, Y. Zeng, X. Zhang, M. Shang, C. Li, and J. Lin, J. Phys. Chem. C 118, 27516 (2014).

M. Hirano and H. Dozono, Mater. Chem. Phys. 143, 860 (2014).

M. Nazarov, Y.J. Kim, E.Y. Lee, K.I. Min, M.S. Jeong, S.W. Lee, and D.Y. Noh, J. Appl. Phys. 107, 103104 (2010).

Y. Lu, C. Chen, S. Li, X. Liu, L. Yan, Y. Dai, A. Zhang, Y. Xie, and X. Tang, Eur. J. Inorg. Chem. 31, 5262 (2015).

E.Y. Lee and Y.J. Kim, Thin Solid Films 518, 72 (2010).

T.S. Sreena, P. Prabhakar Rao, A.K.V. Raj, and T.R. Aju Thara, J. Alloys Compd. 751, 148 (2018).

R.D. Shanmon, Acta Crystallogr. A32, 751 (1976).

M.L. Balmer, Y.L. Su, H.W. Xu, E. Bitten, D. McCready, and A. Navrotsky, J. Am. Cerm. Soc. 84, 153 (2001).

J.I. Langford and A.J.C. Wilson, J. Appl. Crystallogr. 11, 102 (1978).

H.E. Hoefdraad, J. Solid State Chem. 15, 175 (1975).

S.K. Lee, H. Chang, C.H. Han, H.J. Kim, H.G. Jang, and H.D. Park, J. Solid State Chem. 156, 267 (2001).

M. Wiegel, W. Middel, and G. Blasse, J. Mater. Chem. 5, 981 (1995).

C. Hsu and R.C. Powell, J. Lumin. 10, 273 (1975).

B. Yan, J.H. Wu, Y. Bing, and J.-H. Wu, Mater. Chem. Phys. 116, 67 (2009).

C. Liu, J. Liu, and K. Dou, J. Phys. Chem. B. 110, 20277 (2006).

X. Jing, C. Gibbons, D. Nicholas, J. Silver, X. Zhang, A. Vecht, and C.S. Frampton, J. Mater. Chem. 9, 2913 (1999).

A.F. Kirby, D. Foster, and F.S. Richardson, Chem. Phys. Lett. 95, 507 (1983).

H.A. Hoppe, F. Stadler, O. Oeckler, and W. Schnick, Angew. Chem. Int. Ed. 43, 5540 (2004).

O. Oeckler, F. Stadler, T. Rosenthal, and W. Schnick, Solid State Sci. 9, 205 (2007).

J.A. Kechele, O. Oeckler, F. Stadler, and W. Schnick, Solid State Sci. 11, 537 (2009).

Y. Liu, Z.G. Lu, Y.Y. Gu, and W. Li, J. Lumin. 132, 1220 (2012).

T.S. Sreena, P. Prabhakar Rao, A.K.V. Raj, and T.R. Aju Thara, Chem. Sel. 1, 3413 (2016).

J. Hou, X. Yin, Y. Fang, F. Huang, and W. Jiang, Opt. Mater. 34, 1394 (2012).

C.S. McCamy, Color Res. Appl. 17, 142 (1992).

Y.F. Wu, Y.T. Nien, Y.J. Wang, and I.G. Chen, J. Am. Ceram. Soc. 95, 1360 (2012).

Z.P. Lian and Q.F. Yan, J. Mater Chem. C 4, 7959 (2016).

Heading

One of the authors, T. S. Sreena, would like to acknowledge the Department of Science and Technology (DST) INSPIRE Programme (Grant No. IF120735) and the Council of Scientific and Industrial Research (CSIR), Govt. of India, for the research facilities and financial support.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Sreena, T.S., Prabhakar Rao, P., Raj, A.K.V. et al. Strong Narrow Red Emission in a Perturbed Fergusonite System: Y3Mg2Nb3O14:Eu3+ for White LED Applications. J. Electron. Mater. 49, 2332–2342 (2020). https://doi.org/10.1007/s11664-020-07990-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11664-020-07990-6