Abstract

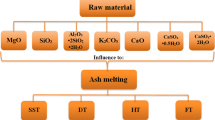

As rice straw has high levels of SiO2 and alkali metals, which tend to form low temperature eutectics during thermo-conversion, by blending Ca-rich biomass, the ash fusion behavior of rice straw may be improved. Ash fusion behavior could not be measurable online, it can be beneficial to use a quickly measured ash composition and predict the ash fusion behavior instantly. In this study, the ash fusibility prediction of rice straw-based ash composition and the effect of Ca-containing layer manure addition on rice straw ash fusibility were investigated. Several significant correlations between ash fusion temperatures of rice straw and ash composition were identified. All the developed equations for AFTs of rice straw ash based on ash composition presented high accuracy with average absolute error < 4%. The deformation and softening temperature of rice straw increased more than 200 °C after adding the layer manure. The layer manure was beneficial for improving rice straw ash fusion characteristics and could replace chemical additives, combing the improved effect of both P and Ca on the ash fusion temperatures. Together with the improvement for the deformation, softening, hemispherical, and flow temperatures of rice straw ash, the 30% mass ration of layer manure could be optimum selection.

Similar content being viewed by others

References

Xue Z, Zhong Z, Zhang B, Zhang J, Xie X (2017) Potassium transfer characteristics during co-combustion of rice straw and coal. Appl Therm Eng 124:1418–1424

Devendra LP, Pandey A (2016) Hydrotropic pretreatment on rice straw for bioethanol production. Renew Energ 98:2–8

He X, Liu Z, Niu W, Yang Y, Zhou T, Qin D, Niu Z, Yuan Q (2018) Effects of pyrolysis temperature on the physicochemical properties of gas and biochar obtained from pyrolysis of crop residues. Energy 143:746–756

Biswas B, Pandey N, Bisht Y, Singh R, Kumar J, Bhaskar T (2017) Pyrolysis of agricultural biomass residues: comparative study of corn cob, wheat straw, rice straw and rice husk. Bioresour Technol 237:57–63

Ren Q, Zhao C, Duan L, Chen X (2011) NO formation during agricultural straw combustion. Bioresour Technol 102:7211–7217

Brand MA, Jacinto RC, Antunes R, da Cunha AB (2017) Production of briquettes as a tool to optimize the use of waste from rice cultivation and industrial processing. Renew Energ 111:116–123

Duan F, Chyang CS, Zhang LH, Yin SF (2015) Bed agglomeration characteristics of rice straw combustion in a vortexing fluidized-bed combustor. Bioresour Technol 183:195–202

Xiong QA, Li J, Guo S, Li G, Zhao J, Fang Y (2018) Ash fusion characteristics during co-gasification of biomass and petroleum coke. Bioresour Technol 257:1–6

Luan C, You C, Zhang D (2014) Composition and sintering characteristics of ashes from co-firing of coal and biomass in a laboratory-scale drop tube furnace. Energy 69:562–570

Touš M, Pavlas M, Stehlík P, Popela P (2011) Effective biomass integration into existing combustion plant. Energy 36:4654–4662

Khan AA, Jong W, Jansens PJ, Spliethoff H (2009) Biomass combustion in fluidized bed boilers: potential problems and remedies. Fuel Process Technol 90:21–50

Xiao H, Li F, Liu Q, Ji S, Fan H, Xu M, Guo Q, Ma M, Ma X (2017) Modification of ash fusion behavior of coal with high ash fusion temperature by red mud addition. Fuel 192:121–127

Ma X, Li F, Ma M, Fang Y (2017) Investigation on blended ash fusibility characteristics of biomass and coal with high silica–alumina. Energ Fuel 31:7941–7951

Wang Y, Wang D, Dong C, Yang Y (2017) The behaviour and reactions of sodium containing minerals in ash melting process. J Energy Inst 90:167–173

Sasi T, Mighani M, Örs E, Tawani R, Gräbner M (2018) Prediction of ash fusion behavior from coal ash composition for entrained-flow gasification. Fuel Process Technol 176:64–75

Link S, Yrjas P, Hupa L (2018) Ash melting behaviour of wheat straw blends with wood and reed. Renew Energ 124:11–20

Deng M, Zhang G, Zeng Y, Pei X, Huang R, Lin J (2016) Simple process for synthesis of layered sodium silicates using rice husk ash as silica source. J Alloys Compd 683:412–417

Li F, Fan H, Guo M, Guo Q, Fang Y (2018) Influencing mechanism of additives on ash fusion behaviors of straw. Energ Fuel 32:3272–3280

Bozaghian M, Rebbling A, Larsson SH, Thyrel M, Xiong S, Skoglund N (2018) Combustion characteristics of straw stored with CaCO3 in bubbling fluidized bed using quartz and olivine as bed materials. Appl Energ 212:1400–1408

Xiong S, Bozaghian M, Lestander TA, Samuelsson R, Hellqvist S, Öhman M (2017) Calcium oxide as an additive for both conservation and improvement of the combustion properties of energy grass: a preliminary study. Biomass Bioenergy 99:1–10

Shen X (2016) Characterization and comparison of energy and fertilizer properties of main animal manure. China Agricultural University, Beijing

International A (2007) ASTM E1757–01, Standard practice for preparation of biomass for compositional analysis.

Ma X, Qin JQ, Luo ZY, Yu CJ, Fang MX, Ceng KF (2010) Effect of additives on fusion characteristic of ashes during rice straw combustion. J ZheJiang Univ Sci B 44:1573–1578

Ma XW, Li FH, Ma MJ, Fang YT (2018) Fusion characteristics of blended ash from Changzhi coal and biomass. J Fuel Chem Technol 46:129–137

GB/T-30726 (2014). Determination of ash fusibility of solid biofuels.

Bai J, Li W, Li B (2008) Characterization of low-temperature coal ash behaviors at high temperatures under reducing atmosphere. Fuel 87:583–591

Kazagic A, Smajevic I, Duic N (2010) Selection of sustainable technologies for combustion of Bosnian coals. Therm Sci 14:715–727

Bridgeman TG, Darvell LI, Jones JM, Williams PT, Fahmi R, Bridgwater AV, Barraclough T, Shield I, Yates N, Thain SC, Donnison IS (2007) Influence of particle size on the analytical and chemical properties of two energy crops. Fuel 86:60–72

Sommersacher P, Brunner T, Obernberger I (2010) Fuel Indexes: a novel method for the evaluation of relevant combustion properties of new biomass fuels. Energy Fuel 26:380–390

Kazagic A, Smajevic I (2009) Synergy effects of co-firing wooden biomass with Bosnian coal. Energy 34:699–707

Wang Y, Tan H, Wang X, Du W, Mikulčić H, Duić N (2017) Study on extracting available salt from straw/woody biomass ashes and predicting its slagging/fouling tendency. J Clean Prod 155:164–171

Zhang Y, He F, Gao Z, You Y, Sun P (2015) Effects of ash-forming temperature on recycling property of bottom ashes from rice residues. Fuel 162:251–257

Niu WJ (2016) Physicochemical composition and energy potential of main crop straw and stalk. China Agricultural University, Beijing

Lynch D, Henihan AM, Kwapinski W, Zhang L, Leahy JJ (2013) Ash agglomeration and deposition during combustion of poultry litter in a bubbling fluidized-bed combustor. Energy Fuel 27:4684–4694

Wang Q, Han K, Gao J, Wang J, Lu C (2017) Investigation of maize straw char briquette ash fusion characteristics and the influence of phosphorus additives. Energy Fuel 31:2822–2830

Rajamma R, Ball RJ, Tarelho LA, Allen GC, Labrincha JA, Ferreira VM (2009) Characterisation and use of biomass fly ash in cement-based materials. J Hazard Mater 172:1049–1060

Komiyama K, Kobayashi A, Yahagi M (2012) The chemical characteristics of ashes from cattle, swine and poultry manure. J Mater Cycles Waste 15:106–110

Qi J, Li H, Han K, Zuo Q, Gao J, Wang Q, Lu C (2016) Influence of ammonium dihydrogen phosphate on potassium retention and ash melting characteristics during combustion of biomass. Energy 102:244–251

Chi H, Pans MA, Sun C, Liu H (2019) An investigation of lime addition to fuel as a countermeasure to bed agglomeration for the combustion of non-woody biomass fuels in a 20kWth bubbling fluidised bed combustor. Fuel 240:349–361

Wang Q, Han K, Wang J, Gao J, Lu C (2017) Influence of phosphorous based additives on ash melting characteristics during combustion of biomass briquette fuel. Renew Energ 113:428–437

Wang L, Skreiberg Ø, Becidan M, Li H (2016) Investigation of rye straw ash sintering characteristics and the effect of additives. Appl Energ 162:1195–1204

Corella J, Toledo JM, Molina G (2008) Performance of CaO and MgO for the hot gas clean up in gasification of a chlorine-containing (RDF) feedstock. Bioresour Technol 99:7539–7544

Acknowledgements

This work was supported by the National Natural Science Foundation of China (Grant No. 51706127), the Natural Science Foundation of Shandong Province (Grant No. ZR2017BEE069), and the Fundamental Research Funds of Shandong University of Technology (Grant No. 416057). We thank Fang Wang, PhD, from Shandong University of Technology for helping us to verify the equations and improve the language and Alex Boon, PhD, from Liwen Bianji, Edanz Editing China (www.liwenbianji.cn/ac) for editing the English text of a draft of this manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shen, X., Zeng, J. Prediction of rice straw ash fusion behaviors and improving its ash fusion properties by layer manure addition. J Mater Cycles Waste Manag 22, 965–974 (2020). https://doi.org/10.1007/s10163-020-00991-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10163-020-00991-x