Abstract

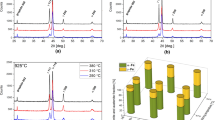

In high-temperature applications, like exhaust manifolds, cast irons with a ferritic matrix are mostly used. However, the increasing demand for higher-temperature applications has led manufacturers to use additional expensive materials such as stainless steels and Ni-resist austenitic ductile cast irons. Thus, in order to meet the demand while using low-cost materials, new alloys with improved high-temperature strength and oxidation resistance must be developed. In this study, thermodynamic calculations with Thermo-Calc software were applied to study a novel ductile cast iron with a composition of 3.5wt% C, 4wt% Si, 1wt% Nb, 0–4wt% Al. The designed compositions were cast, and thermal analysis and microstructural characterization were performed to validate the calculations. The lowest critical temperature of austenite to pearlite eutectoid transformation, i.e., A1, was calculated, and the solidification sequence was determined. Both calculations and experimental data revealed the importance of aluminum addition, as the A1 increased by increasing the aluminum content in the alloys, indicating the possibility of utilizing the alloys at higher temperature. The experimental data validated the transformation temperature during solidification and at the solid state and confirmed the equilibrium phases at room temperature as ferrite, graphite, and MC-type carbides.

Similar content being viewed by others

References

A.A. Partoaa, M. Abdolzadeh, and M. Rezaeizadeh, Effect of fin attachment on thermal stress reduction of exhaust manifold of an off road diesel engine, J. Cent. South Univ., 24(2017), No. 3, p. 546.

Y.H. Zhang, M. Li, L.A. Godlewski, J.W. Zindel, and Q. Feng, Creep behavior at 1273 K (1000°C) in Nb-bearing austenitic heat-resistant cast steels developed for exhaust component applications, Metall. Mater. Trans. A, 47(2016), No. 7, p. 3289.

M. Ekström and S. Jonsson, High-temperature mechanical- and fatigue properties of cast alloys intended for use in exhaust manifolds, Mater. Sci. Eng. A, 616(2014), p. 78.

L.M. Åberg and C. Hartung, Solidification of SiMo nodular cast iron for high temperature applications, Trans. Indian Inst. Met., 65(2012), No. 6, p. 633.

J.P. Shingledecker, P.J. Maziasz, N.D. Evans, and M.J. Pollard, Creep behavior of a new cast austenitic alloy, Int. J. Press. Vessels Pip., 84(2007), No. 1–2, p. 21.

M.M. Ibrahim, A. Nofal, and M.M. Mourad, Microstructure and hot oxidation resistance of SiMo ductile cast irons containing Si-Mo-Al, Metall. Mater. Trans. B, 48(2017), No. 2, p. 1149.

Y.H. Zhang, M. Li, L.A. Godlewski, J.W. Zindel, and Q. Feng, Effective design of new austenitic cast steels for ultra-high temperature automotive exhaust components through combined CALPHAD and experimental approaches, Mater. Sci. Eng. A, 683(2017), p. 195.

F. Tholence and M. Norell, High temperature corrosion of cast alloys in exhaust environments I-ductile cast irons, Oxid. Met., 69(2008), No. 1–2, p. 13.

M. Ekström, P. Szakalos, and S. Jonsson, Influence of Cr and Ni on high-temperature corrosion behavior of ferritic ductile cast iron in air and exhaust gases, Oxid. Met., 80(2013), No. 5–6, p. 455.

F. Tholence and M. Norell, High temperature corrosion of cast alloys in exhaust environments II-cast stainless steels, Oxid. Met., 69(2008), No. 1–2, p. 37.

Y.H. Zhang, M.L. Larry, L.A. Godlewski, J.W. Zindel, and Q. Feng, Effects of W on creep behaviors of novel Nb-bearing high nitrogen austenitic heat-resistant cast steels at 1000°C, Mater. Charact., 139(2018), p. 19.

M.P. Brady, G. Muralidharan, D.N. Leonard, J.A. Haynes, R.G. Weldon, and R.D. England, Long-term oxidation of candidate cast iron and stainless steel exhaust system alloys from 650 to 800°C in air with water vapor, Oxid. Met., 82(2014), No. 5–6, p. 359.

G.M.C. Güiza, W. Hormaza, A.R. Galvis E, and L.M.M. Morenod, Bending overload and thermal fatigue fractures in a cast exhaust manifold, Eng. Fail. Anal., 82(2017), p. 138.

J.W. Soedarsono, T.P. Soemardi, B. Suharno, and R.D. Sulamet-Ariobimo, Effects of carbon equilavent on the microstructures of thin wall ductile iron, J. Mater. Sci. Eng., 5(2011), No. 3, p. 266.

G.E. Totten, Steel Heat Treatment Handbook, Chemical Rubber Company Press, Boca Raton, 2006.

H. Bhadeshia and R. Honeycombe, Steels: Microstructure and Properties, Elsevier, Oxford, 2006.

A.R.K. Rashid and D.V. Edmonds, Oxidation behaviur of Al-alloyed ductile cast irons at elevated temperature, Surf. Interface Anal., 36(2004), No. 8, p. 1011.

A. Hassani, A. Habibolahzadeh, and S. Sadeghinejad, Comparison of microstructural and tribological effects of low vanadium-low titanium additions to a gray cast iron, J. Mater. Eng. Perform., 22(2013), No. 1, p. 267.

T.N.F. Souzo, R.A.P.S. Nogueira, F.J.S. Franco, M.T.P. Aguilar, and P.R. Cetlin, Mechanical and microstructural characterization of nodular cast iron (NCI) with niobium additions, Mater. Res., 17(2014), No. 5, p. 1167.

Y.Z. Lv, Y.F. Sun, J.Y. Zhao, G.W. Yu, J.J. Shen, and S.M. Hu, Effect of tungsten on microstructure and properties of high chromium cast iron, Mater. Des., 39(2012), p. 303.

C. Delprete and R. Sesana, Experimental characterization of Si-Mo-Cr ductile cast iron, Mater. Des., 57(2014), p. 528.

A. Bedolla-Jacuindde, E. Solis, and B. Hernandez, Effect of niobium in medium alloyed ductile cast irons, Int. J. Cast Met. Res., 16(2003), No. 5, p. 481.

D.X. Zeng, Y.H. Zhang, J.Y. Liu, H.J. He, and X.X. Hong, Characterization of titanium-containing compounds in gray iron, Tsinghua Sci. Technol., 13(2008), No. 2, p. 127.

M. Gómy and M. Kawalec, Effects of titanium addition on microstructure and mechanical properties of thin-walled compacted graphite iron castings, J. Mater. Eng. Perform., 22(2013), No. 5, p. 1519.

X.R. Chen, J. Xu, H. Hu, H. Mohrbacher, M. Kang, W. Zhang, A.M. Guo, and Q.J. Zhai, Effects of niobium addition on microstructure and tensile behavior of as-cast ductile iron, Mater. Sci. Eng. A, 688(2017), p. 416.

T. Elbel and J. Hampl, Influence of Al and Ti on microstructure and quality of compacted graphite iron casting, Metalurgija, 48(2009), No. 4, p. 243.

M. Gómy and M. Kawalec, Role of titanium in thin wall vermicular graphite iron casting production, Arch. Foundry Eng., 13(2013), No. 2, p. 25.

C.A. Cooper, R. Elliott, and R.J. Young, Investigation of elastic property relationships for flake and spheroidal cast irons using Raman spectroscopy, Acta Mater., 50(2002), No. 16, p. 4037.

H. Nakae and H. Shin, Effect of graphite morphology on tensile properties of flake graphite cast iron, Mater. Trans., 42(2001), No. 7, p. 1428.

D. Holmgren, A. Diószegi, and I.L. Svensson, Effects of nodularity on thermal conductivity of cast iron, Int. J. Cast Met. Res., 20(2007), No. 1, p. 30.

V. Gautam, S. Ahuja, and N. Ram, Design and solidification simulation of exhaust manfold made of SiMo ductile cast iron, ELK Asia Pac. J., (2017), p. 978.

P.H. Huang, J.K. Kuo, T.H. Fang, and W.R. Wu, Numerical simulation and design of casting system for stainless steel exhaust manifold, MATEC Web Conf., 185(2018), p. 8.

B.M. Moon, S.M. Lee, and C.P. Hong, Alloy design for a low thermal expansion cast iron with enhanced mechanical properties, Int. J. Cast Met. Res., 11(1999), No. 6, p. 573.

J.S. Aristeidakis and G.N. Haidemenopoulos, Alloy design based on computational thermodynamics and multi-objective optimization: the case of medium-Mn steels, Metall. Mater. Trans. A, 48(2017), No. 5, p. 2584.

U.R. Kattner, The Calphad method and its role in material and process development, Technol. Met. Mater. Min., 13(2016), No. 1, p. 3.

H.L. Lukas, S.G. Fries, and B. Sundman, Computyational Thermodynamics: The Calphad Method, Cambridge University Press, New York, 2007.

Y.J. Soo, M.P. Phaniraj, D.I. Kim, J.H. Shim, and M.Y. Huh, Effect of aluminum content on the microstructure and mechanical properties of hypereutectoid steels, Metall. Mater. Trans. A, 41(2010), No. 8, p. 2078.

T. Seifert and H. Riedel, Mechanism-based thermomechanical fatigue life prediction of cast iron. part I: models, Int. J. Fatigue, 32(2010), No. 8, p. 1358.

C.P. Sharma, Engineering Materials: Properties and Applications of Metals and Alloys, New Delhi, Prentice-Hall, 2004.

Z. Yang, X.P. Liu, J. Fu, X.S. Zhao, L.J. Jiang, and S.M. Wang, Thermal expansion properties of Fe-Ni-Co superinvar alloy with Mn, Chin. J. Rare Met., 37(2013), No. 3, p. 501.

Y.Z. Liu, Y.F. Li, J.D. Xing, S.G. Wang, B.C. Zheng, D. Tao, and W. Li, Effect of graphite morphology on the tensile strength and thermal conductivity of cast iron, Mater. Charact., 144(2018), p. 155.

T. Matsushita, E. Ghassemali, A.G. Saro, L. Elmquist, and A.E.W. Jarfors, On thermal expansion and density of CGI and SGI cast irons, Metals, 5(2015), p. 1000.

M.S. Soiński, A. Jakubus, and G. Stradomski, The influence of aluminium on the spheroidization of cast iron assessed on the basis of wedge test, Arch. Foundry Eng., 13(2013), No. 2, p. 163.

D.L. Li, Discussion of “microstructure and hot oxidation resistance of SiMo ductile cast irons containing Si-Mo-Al”, Metall. Mater. Trans. B, 49(2018), No. 2, p. 858.

E. Kozeschnik and H.K.D.H. Bhadeshia, Influence of silicon on cementite precipitation in steels, Mater. Sci. Technol., 24(2008), No. 3, p. 343.

B. Cygan, M. Stawarz, and J. Jezierski, Heat treatment of the SiMo iron castings-case study in automotive foundry, Arch. Foundry Eng., 18(2018), No. 4, p. 103.

Acknowledegements

The authors, G. Aktaş Çelik, Ş. Polat and Ş. H. Atapek wish to acknowledge the financial support given by Scientific Research Projects Coordination Unit of Kocaeli University under the project No. 2017/118.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Çelik, G.A., Tzini, MI.T., Polat, Ş. et al. Thermal and microstructural characterization of a novel ductile cast iron modified by aluminum addition. Int J Miner Metall Mater 27, 190–199 (2020). https://doi.org/10.1007/s12613-019-1876-8

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-019-1876-8