Abstract

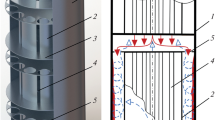

Vortex contact devices for gas introduction have been developed and studied. The devices make it possible to increase the gas and liquid loading on stages compared with valve and cap devices, to reduce the fluctuations of the gas–liquid medium on the liquid surface, and to increase the separation efficiency. Based on the experimental studies and numerical modeling, a scheme of liquid and gas motion at the stage was developed, and the velocity profiles during bubbling were calculated. The stage parameters were determined: hydraulic resistance, gas content, average surface diameter of bubbles, interphase surface area, efficiency, and mass transfer coefficients. The dependences for their calculation were presented. A vortex stage for the exhausting distillation column was designed, which provides a 1.5-fold reduction of metal consumption and increased efficiency at a velocity factor of up to 3 Pa0.5 and spray rate of 78 m3/(h m2) compared with the standard cap plate.

Similar content being viewed by others

REFERENCES

Akhmetov, S.A., Serikov, T.P., Kuzeev, I.R., and Bayazitov, M.I., Tekhnologiya i oborudovanie protsessov pererabotki nefti i gaza: uchebnoe posobie (Technologies and Equipment for Oil and Gas Processing: A Textbook), St. Petersburg: Nedra, 2006.

Voinov, N.A., Zhukova, O.P., and Voronin, S.M., Results of introduction and study of the contact stages of beer columns, Izv. Vyssh. Uchebn. Zaved., Lesn. Zh., 2011, no. 4, p. 93.

Naziri, N., Zadghaffari, R., and Naziri, H., CFD simulation and experimental study of new developed centrifugal trays, Int. J. Chem. Eng. Appl., 2012, vol. 3, no. 3, pp. 201–205.

Belov, S.A. and Orazova, M.A., Centrifugal trays. Design of decks for strength and rigidity, Chem. Technol. Fuels Oils, 2006, vol. 42, no. 5, pp. 374–376. https://doi.org/10.1007/s10553-006-0090-3

Lebedev, Yu.N., High-performance centrifugal trays, Chem. Technol. Fuels Oils, 2004, vol. 40, no. 1, pp. 55–58. https://doi.org/10.1023/B:CAFO.0000021595.77193.b7

Lebedev, Yu.N., Chekmenev, V.G., and Danilov, D.Yu., Testing new centrifugal trays with liquid recirculation, Chem. Technol. Fuels Oils, 2010, vol. 46, no. 4, pp. 262–267. https://doi.org/10.1007/s10553-010-0221-8

Wilkinson, P., Vos, E., Konijn, G., Kooijman, H., Mosca, G., and Tonon, L., Distillation trays that operate beyond the limits of gravity by using centrifugal separation, Chem. Eng. Res. Des., 2007, vol. 85, no. 1, pp. 130–135. https://doi.org/10.1205/cherd06103

Yang, Q., Mosca, G., and Roza, M., Characteristics of trays using inertial separation technology, Chin. J. Chem. Eng., 2010, vol. 18, no. 6, pp. 954–961. https://doi.org/10.1016/S1004-9541(09)60153-1

Nikolaev, N.A., Zhavoronkov, N.M., and Malyusov, V.A., Calculation of distillation columns with cocurrent vortex contact devices, Teor. Osn. Khim. Tekhnol., 1974, vol. 8, no. 6, p. 853.

Savel’ev, N.I., Voinov, N.A., and Nikolaev, N.A., Patterns of mass transfer in cocurrent film contact devices in the distillation of binary mixtures, Teor. Osn. Khim. Tekhnol., 1983, vol. 17, no. 2, p. 254.

Voinov, N.A., Zhukova, O.P., Lednik, S.A., and Nikolaev, N.A., Mass transfer in gas–liquid layer on vortex contact stages, Theor. Found. Chem. Eng., 2013, vol. 47, no. 1, pp. 55–59. https://doi.org/10.1134/S0040579513010132

Voinov, N.A. and Lednik, S.A., Hydrodynamics and mass transfer on a stage with profiled tangential channels, Khim.Prom-st., 2011, vol. 88, no. 5, p. 250.

Voinov, N.A., Zhukova, O.P., and Nikolaev, N.A., Hydrodynamics of the vortex stage with tangential swirlers, Theor. Found. Chem. Eng., 2010, vol. 44, no. 2, pp. 213–219. https://doi.org/10.1134/S0040579510020132

Shahbazi, B., Rezai, B., Chelgani, S.C., Koleini, S.M.J., and Noaparast, M., Estimation of diameter and surface area flux of bubbles based on operational gas dispersion parameters by using regression and ANFIS, Int. J. Min. Sci. Technol., 2013, vol. 23, no. 3, pp. 343–348. https://doi.org/10.1016/j.ijmst.2013.05.007

Ostrovskii, G.M., Prikladnaya mekhanika neodnorodnykh sred (Applied Mechanics of Inhomogeneous Media), St. Petersburg: Nauka, 2000.

Lapteva, E.A. and Laptev, A.G., Prikladnye aspekty yavlenii perenosa v apparatakh khimicheskoi tekhnologii i teploenergetiki (gidrodinamika i teplomassoobmen) (Applied Aspects of Transport Phenomena in Apparatuses of Chemical Engineering and Thermal Power Engineering: Hydrodynamics and Heat and Mass Transfer), Kazan: Pechat’-Serviz XXI Veka, 2015.

Abd Ali, K.M., CFD simulation of bubbly flow through a bubble column, Int. J. Sci. Eng. Res., 2014, vol. 5, no. 4, pp. 904–910.

Schwarz, M.P. and Turner, W.J., Applicability of the standard k-ϵ turbulence model to gas-stirred baths, Appl. Math. Modell., 1988, vol. 12, no. 3, pp. 273–279. https://doi.org/10.1016/0307-904X(88)90034-0

Protsessy i apparaty khimicheskoi tekhnologii. Yavleniya perenosa, makrokinetika, podobie, modelirovanie, proektirovanie. T. 2. Mekhanicheskie i gidromekhanicheskie protsessy (Processes and Equipment in Chemical Engineering: Transport Phenomena, Macrokinetics, Similarity, Modeling, and Design, vol. 2: Mechanical and Hydromechanical Processes), Kutepov, A.M., Ed., Moscow: Logos, 2001.

Voinov, N.A., Zemtsov, D.A., Zhukova, O.P., and Bogatkova, A.V., Hydraulic resistance of tangential swirlers, Chem. Pet. Eng., 2019, vol. 55, nos. 1–2, pp. 51–56. https://doi.org/10.1007/s10556-019-00584-y

Voinov, N.A., Zhukova, O.P., and Konovalov, N.M., Hydrodynamics and heat transfer during boiling in a rotating gas–liquid layer, Theor. Found. Chem. Eng., 2018, vol. 52, no. 6, pp. 987–995. https://doi.org/10.1134/S0040579518060143

Dytnerskii, Yu.I., Protsessy i apparaty khimicheskoi tekhnologii. V 2-kh tomakh (Processes and Equipment in Chemical Engineering, 2 vols.), Moscow: Khimiya, 1991.

Laptev, A.G., Farakhov, M.I., and Mineev, N.G., Osnovy rascheta i modernizatsiya teplomassoobmennykh ustanovok v neftekhimii. Monografiya (Fundamentals of Calculation and Modernization of Heat and Mass Transfer Installations in Petroleum Chemistry: A Monograph), Kazan: Kazan. Gos. Energ. Univ., 2010.

Ponikarov, I.I. and Gainulin, M.G., Mashiny i apparaty khimicheskikh proizvodstv i neftegazopererabotki. Uchebnik (Machinery and Equipment of Chemical Plants and Oil and Gas Processing: A Textbook), Moscow: Al’fa-M, 2006.

Timonin, A.S., Baldin, B.G., Borshchev, V.Ya., Gusev, Yu.I., et al., Mashiny i apparaty khimicheskikh proizvodstv. Uchebnik dlya vuzov (Machinery and Equipment of Chemical Plants: A Textbook for Institutions of Higher Education), Kaluga: Noosfera, 2014.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated by L. Smolina

Rights and permissions

About this article

Cite this article

Voinov, N.A., Frolov, A.S., Bogatkova, A.V. et al. Hydrodynamics and Mass Transfer at the Vortex Stage and during Bubbling. Theor Found Chem Eng 53, 972–983 (2019). https://doi.org/10.1134/S0040579519060149

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1134/S0040579519060149