Abstract

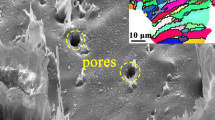

The arc-spray-coated Q235/AZ91D bimetallic material was fabricated via casting the molten magnesium alloy into the mold where arc-spray-coated Q235 had been inserted to realize the light weight with optimal mechanical properties. The microstructure and mechanical properties of arc-spray-coated Q235/AZ91D bimetallic material were investigated in this study. Results revealed that the interface zone between Q235 and AZ91D could be divided into two different layers: the layer close to AZ91D and the layer adjacent to Q235. The layer close to AZ91D was composed of α-Mg and Al5Mg11Zn4, and the layer adjacent to Q235 was comprised of α-Mg, FeAl3 and MgAl2O4. Due to the inhomogeneous distribution of magnesium, aluminum and zinc elements, the white phase in the layer adjacent to AZ91D displayed several different morphologies including ellipse, strip and mesh, resulting in the variation of hardness from 152.3HV to 332.4HV. In addition, the generation of MgAl2O4 and FeAl3 caused the hardness of the layer close to AZ91D to reach 332.6HV. What is more, the shear test indicated the shear strength of arc-spray-coated Q235/AZ91D bimetallic material was much better than the bare Q235/AZ91D bimetallic material, which was attributed to the formation of metallurgical bonding.

Similar content being viewed by others

References

G. Arruebarrena, I. Hurtado, J. Väinölä, C. Cingi, S. Dévényi, J. Townsend, S. Mahmood, A. Wendt, K. Weiss, A. Ben-Dov, Adv. Eng. Mater. 9, 751 (2007)

T.E.B.L. Mordike, Mat. Sci. Eng. A-Struct. 302, 37 (2001)

F. Pan, M. Yang, X. Chen, J. Mater. Sci. Technol. 32(12), 1211 (2016)

G. Song, Adv. Eng. Mater. 7(7), 563 (2005)

A. Atrens, G.L. Song, Adv. Eng. Mater. 1, 11 (1999)

A.Z.-H. Pooriya Dastranjy Nezhadfar, S.S. Sohn, H.R. Abedi, Mater. Sci. Eng. A-Struct. 665, 10–16 (2016)

H.M.M. Yamashita, Y. Matsuda, H. Nagano, T. Misawa, Corros. Sci. 36(2), 283 (1994)

ASM International, Alloy Phase Diagrams of ASM Handbook, 8th edn.(1992)

B.C.W. Tan, B. Chen, X.G. Song, L. Zhou, S.H. Meng, L.Q. Li, J.C. Feng, Weld. J. 95, 384 (2016)

J.-H. Zhao, W.-Q. Zhao, S. Qu, Y.-Q. Zhang, Trans. Nonferr. Metal. Soc. 29(1), 51 (2019)

D.Q.S.X.Y. Wang, Y. Sun, Z.Q. Ding, Mater. Trans. 56(11), 1868 (2015)

X.Y. Wang, D.Q. Sun, Y. Sun, J. Mater. Eng. Perform. 25(3), 910 (2016)

D. Ren, L. Liu, Mater. Des. 59, 369 (2014)

R. Cao, J.H. Chang, Q. Huang, X.B. Zhang, Y.J. Yan, J.H. Chen, J. Manuf. Process. 31, 674 (2018)

A.M. Nasiri, Y. Zhou, Sci. Technol. Weld. J. 20(2), 155 (2014)

R. Cao, H.X. Zhu, Q. Wang, C. Dong, Q. Lin, J.H. Chen, Mater. Sci. Tech.-Lond. 32(18), 1805 (2016)

L. Li, C. Tan, Y. Chen, W. Guo, X. Hu, Metall. Mater. Trans. A. 43(12), 4740 (2012)

G. Song, C. Shan, Mater. Res. Innov. 15(2), 145 (2013)

L. Liu, X. Qi, Mater. Des. 31(8), 3960 (2013)

V.K. Patel, S.D. Bhole, D.L. Chen, J. Mater. Process. Tech. 214(4), 811 (2014)

M. Sun, S.B. Behravesh, L. Wu, Y. Zhou, H. Jahed, Fatigue Fract. Eng. M 40(7), 1048 (2017)

L. Liu, X. Qi, Z. Wu, Mater. Lett. 64(1), 89 (2010)

S. Liu, D. Sun, X. Gu, H. Li, J. Mater. Res. 32(04), 843 (2017)

M. Ohno, D. Mirkovic, R. Schmid-Fetzer, Mater. Sci. Eng. A-Struct. 421(1–2), 328 (2006)

L. Bourgeois, B.C. Muddle, J.F. Nie, Acta Mater. 49, 2701 (2001)

Acknowledgments

This work was funded by the National Natural Science Foundation of China (No. 51875062). In addition, this work was partly supported by the National Engineering Research Centre for Magnesium Alloys of China.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Cheng, J., Zhao, Jh., Zheng, D. et al. Investigation on the Microstructure and Mechanical Properties of Arc-Spray-Coated Q235/AZ91D by Solid–Liquid Compound Casting. Inter Metalcast 14, 518–527 (2020). https://doi.org/10.1007/s40962-019-00380-7

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00380-7