Abstract

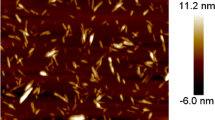

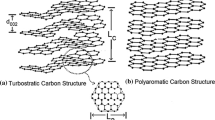

For the first time, we map the conditions that lead to the successful preparation of carbon nanofibers from a blend of lignin and recycled poly(ethylene terephthalate) (r-PET). Particularly, we describe how their morphology depends on the synergy between the lignin/r-PET mass ratio and the average fiber diameter of the precursor fibers. Electrospun mats consisting of different lignin/r-PET mass ratios (from 50/50 to 90/10) and different average fiber diameters (from 80 to 400 nm) were prepared. After carbonizing them to 600 °C, it was repeatedly observed that the samples having a relatively high mass ratio of r-PET (> 33 wt%) and low average fiber diameters (~ 100 nm) exhibit extensive melting and the fibrous structure collapses. In contrast, samples of the same high mass ratio of r-PET but large average fiber diameters (> 300–400 nm) yield infusible filamentous carbon structures. This nano-dimension phenomenon declines when the r-PET content is low enough (~ 10 wt%). In this case, the nanofibers are practically infusible and carbon nanofibers with average diameters close to 100 nm and a well-formed filamentous structure are produced. Such thin lignin-based carbon nanofibers have scarcely been reported. The reasons leading to the melting of the nanofibrous mats which consist of certain mass ratios and average fiber diameters are related to variations in the decomposition rates of the two precursor polymers and also to differences in their crystallization. These phenomena are explained based on experimental results from thermogravimetry, X-ray diffraction and differential scanning calorimetry. Moreover, BET surface area measurements indicate that the melting of nanofibrous mats compromises the porosity of the activated carbon nanofibers produced from them, while the presence of r-PET has a positive impact on the development of porosity.

Similar content being viewed by others

References

Ago M, Borghei M, Haataja JS, Rojas OJ (2016) Mesoporous carbon soft-templated from lignin nanofiber networks: Microphase separation boosts supercapacitance in conductive electrodes. RSC Adv 6:85802–85810. https://doi.org/10.1039/c6ra17536h

Alekhina M, Erdmann J, Ebert A et al (2015) Physico-chemical properties of fractionated softwood kraft lignin and its potential use as a bio-based component in blends with polyethylene. J Mater Sci 50:6395–6406. https://doi.org/10.1007/s10853-015-9192-9

Baker DA, Rials TG (2013) Recent advances in low-cost carbon fiber manufacture from lignin. J Appl Polym Sci 130:713–728. https://doi.org/10.1002/app.39273

Beck RJ, Zhao Y, Fong H, Menkhaus TJ (2017) Electrospun lignin carbon nanofiber membranes with large pores for highly efficient adsorptive water treatment applications. J Water Process Eng 16:240–248. https://doi.org/10.1016/j.jwpe.2017.02.002

Choi DI, Lee J-N, Song J et al (2013) Fabrication of polyacrylonitrile/lignin-based carbon nanofibers for high-power lithium ion battery anodes. J Solid State Electrochem 17:2471–2475. https://doi.org/10.1007/s10008-013-2112-5

Dallmeyer I, Lin LT, Li Y et al (2014) Preparation and characterization of interconnected, kraft lignin-based carbon fibrous materials by electrospinning. Macromol Mater Eng 299:540–551. https://doi.org/10.1002/mame.201300148

Dong S, Jia Y, Xu X et al (2019) Crystallization and properties of poly(ethylene terephthalate )/layered double hydroxide nanocomposites. J Colloid Interface Sci 539:54–64

Duval A, Lawoko M (2014) A review on lignin-based polymeric, micro- and nano-structured materials. React Funct Polym 85:78–96. https://doi.org/10.1016/j.reactfunctpolym.2014.09.017

Frank E, Steudle LM, Ingildeev D et al (2014) Carbon fibers: precursor systems, processing, structure, and properties. Angew Chemie Int Ed 53:5262–5298. https://doi.org/10.1002/anie.201306129

García-Mateos FJ, Cordero-Lanzac T, Berenguer R et al (2017) Lignin-derived Pt supported carbon (submicron) fiber electrocatalysts for alcohol electro-oxidation. Appl Catal B Environ 211:18–30. https://doi.org/10.1016/j.apcatb.2017.04.008

Inagaki M, Yang Y, Kang F (2012) Carbon nanofibers prepared via electrospinning. Adv Mater 24:2547–2566. https://doi.org/10.1002/adma.201104940

Jin J, Yu BJ, Shi ZQ et al (2014) Lignin-based electrospun carbon nanofibrous webs as free-standing and binder-free electrodes for sodium ion batteries. J Power Sour 272:800–807. https://doi.org/10.1016/j.jpowsour.2014.08.119

Jönsson P, Evangelopoulos P, Persson H, Han T, Sophonrat N, Yang W (2018) Evolution of sulfur during fast pyrolysis of sulfonated Kraft lignin. J Anal Appl Pyrolysis 133:162–168. https://doi.org/10.1016/j.jaap.2018.04.006

Kadla JF, Kubo S (2004) Lignin-based polymer blends: analysis of intermolecular interactions in lignin–synthetic polymer blends. Compos Part A Appl Sci Manuf 35:395–400. https://doi.org/10.1016/j.compositesa.2003.09.019

Ko F, Wan Y (2014a) Introduction to nanofiber materials, Chapter 3. Cambridge University Press, Cambridge

Ko F, Wan Y (2014b) Introduction to nanofiber materials, Chapter 6. Cambridge University Press, Cambridge

Ko K, Rawal A, Sahajwalla V (2014) Analysis of thermal degradation kinetics and carbon structure changes of co-pyrolysis between macadamia nut shell and PET using thermogravimetric analysis and 13 C solid state nuclear magnetic resonance. Energy Convers Manag 86:154–164. https://doi.org/10.1016/j.enconman.2014.04.060

Lallave M, Bedia J, Ruiz-Rosas R et al (2007) Filled and hollow carbon nanofibers by coaxial electrospinning of Alcell lignin without binder polymers. Adv Mater 19:4292–4296. https://doi.org/10.1002/adma.200700963

Ma C, Li Z, Li J et al (2018) Lignin-based hierarchical porous carbon nanofiber films with superior performance in supercapacitors. Appl Surf Sci 456:568–576. https://doi.org/10.1016/j.apsusc.2018.06.189

Mazinani S, Ajji A, Dubois C (2010) Fundamental study of crystallization, orientation, and electrical conductivity of electrospun PET/carbon nanotube nanofibers. J Polym Sci Part B Polym Phys 48:2052–2064. https://doi.org/10.1002/polb.22085

Mohabeer C, Reyes L, Abdelouahed L, Marcotte S, Taouk B (2019) Investigating catalytic de-oxygenation of cellulose, xylan and lignin bio-oils using HZSM-5 and Fe-HZSM-5. J Anal Appl Pyrolysis 137:118–127. https://doi.org/10.1016/j.jaap.2018.11.016

NAPCOR (2018) National association for PET container resources of USA. https://www.napcor.com/PET/landing_petrecycling.html. Accessed 20 Mar 2018

Peng S, Li L, Kong J et al (2016) Electrospun carbon nanofibers and their hybrid composites as advanced materials for energy conversion and storage. Nano Energy 22:361–395. https://doi.org/10.1016/j.nanoen.2016.02.001

Rodríguez Correa C, Stollovsky M, Hehr T et al (2017) Influence of the carbonization process on activated carbon properties from lignin and lignin-rich biomasses. ACS Sustain Chem Eng 5:8222–8233. https://doi.org/10.1021/acssuschemeng.7b01895

Ruiz-Rosas R, Bedia J, Lallave M et al (2010) The production of submicron diameter carbon fibers by the electrospinning of lignin. Carbon 48:696–705. https://doi.org/10.1016/j.carbon.2009.10.014

Sun P, Lu H, Zhang W et al (2018) Poly(ethylene terephthalate): rubbish could be low cost anode material of lithium ion battery. Solid State Ionics 317:164–169. https://doi.org/10.1016/j.ssi.2018.01.024

Svinterikos E, Zuburtikudis I (2016) Carbon nanofibers from renewable bioresources (lignin) and a recycled commodity polymer [poly(ethylene terephthalate)]. J Appl Polym Sci 133:43936. https://doi.org/10.1002/app.43936

Svinterikos E, Zuburtikudis I (2017) Tailor-made electrospun nanofibers of biowaste lignin/recycled poly(ethylene terephthalate). J Polym Environ 25:465–478. https://doi.org/10.1007/s10924-016-0806-3

Svinterikos E, Zuburtikudis I, Al-Marzouqi M (2019) The nanoscale dimension determines the carbonization outcome of electrospun lignin/recycled-PET fibers. Chem Eng Sci 202:26–35. https://doi.org/10.1016/j.ces.2019.03.013

Thakur VK, Thakur MK, Raghavan P, Kessler MR (2014) Progress in green polymer composites from lignin for multifunctional applications: a review. ACS Sustain Chem Eng 2:1072–1092. https://doi.org/10.1021/sc500087z

Thomas D, Schick C, Cebe P (2018) Novel method for fast scanning calorimetry of electrospun fibers. Thermochim Acta 667:65–72. https://doi.org/10.1016/j.tca.2018.07.001

Wang C-Q, Wang H, Liu Y-N (2015) Separation of polyethylene terephthalate from municipal waste plastics by froth flotation for recycling industry. Waste Manag 35:42–47. https://doi.org/10.1016/j.wasman.2014.09.025

Wool RP, Sun XS (2005) Bio-based polymers and composites. Bio-Based Polym Compos. https://doi.org/10.1016/B978-012763952-9/50017-4

Zhang M, Resende FLP, Moutsoglou A, Raynie DE (2012) Pyrolysis of lignin extracted from prairie cordgrass, aspen, and Kraft lignin by Py-GC/MS and TGA/FTIR. J Anal Appl Pyrolysis 98:65–71. https://doi.org/10.1016/j.jaap.2012.05.009

Zhang B, Kang F, Tarascon J, Kim J (2016) Recent advances in electrospun carbon nanofibers and their application in electrochemical energy storage. Prog Mater Sci 76:319–380. https://doi.org/10.1016/j.pmatsci.2015.08.002

Acknowledgements

The authors would like to acknowledge the financial support provided by the Emirates Center for Energy and Environment Research (Grant number 31R147).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Svinterikos, E., Zuburtikudis, I. & Al-Marzouqi, M. Fabricating carbon nanofibers from a lignin/r-PET blend: the synergy of mass ratio with the average fiber diameter. Appl Nanosci 10, 1331–1343 (2020). https://doi.org/10.1007/s13204-019-01235-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s13204-019-01235-7