Abstract

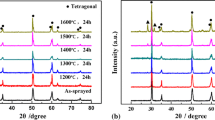

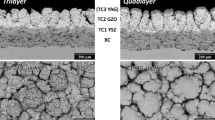

In this research, thermal cyclic fatigue (TCF) behavior of a compositionally graded layer (CGL) nanostructured coating was investigated and compared with the TCF behavior of a micro-CGL coating. The layers, as a thermal barrier coating (TBC), were made from nanostructured and/or conventional micro-sized yttria-stabilized zirconia (YSZ) and NiCrAlY powders. According to the composition of each layer, a certain ratio of YSZ/NiCrAlY powder was mixed and deposited by air plasma spray process on IN 738-LC as a substrate. In order to investigate the effect of temperature on the lifetime of coatings, TCF tests were conducted at two different high temperatures (900 and 1100 °C). These tests were done by holding the samples at the mentioned temperatures for 1 h and then fast cooling to 100 °C by compressed air for 10 min. Microstructural evaluation showed that there were some differences between the damage mechanisms of these two groups of compositionally graded TBCs. The results also showed that the average thermal cyclic lifetime of nanostructured compositionally graded TBCs is approximately 1.6 times higher than that of the micro-one. Moreover, it was indicated that the presence of much more spinel oxide regions formed at higher temperature has a remarkable effect on the lifetime of compositionally graded TBCs.

Graphical Abstract

Similar content being viewed by others

References

U. Leushake, T. Krell, U. Schulz, Materials Science and Engineering Technology 28, 391 (2004). https://doi.org/10.1002/mawe.19970280817.

N.P. Padture, M. Gell, and E.H. Jordan, Science 296, 280 (2002). https://doi.org/10.1126/science.1068609.

M. Hatami, F. Naeimi, M. Shamanian, and M. Tahari, Oxidation of Metals 90, 153 (2018). https://doi.org/10.1007/s11085-017-9829-y.

K. Ito, H. Kuriki, H. Araki, S. Kuroda, and M. Enoki, Science and Technology of Advanced Materials 15, 35007 (2014). https://doi.org/10.1088/1468-6996/15/3/035007.

J. T. DeMasi-Marcin, and D. K. Gupta, Surface and Coatings Technology 68–69, 1 (1994). https://doi.org/10.1016/0257-8972(94)90129-5.

K. M. Doleker, H. Ahlatci, and A. C. Karaoglanli, Oxidation of Metals 88, 109 (2017). https://doi.org/10.1007/s11085-016-9690-4.

D. Stöver, G. Pracht, H. Lehmann, M. Dietrich, J.-E. Döring, and R. Vassen, Journal of Thermal Spray Technology 13, 76 (2004). https://doi.org/10.1007/s11666-004-0052-4.

J. A. Thompson, and T. W. Clyne, Acta Materialia 49, 1565 (2001). https://doi.org/10.1016/S1359-6454(01)00065-9.

G. Shanmugavelayutham, and A. Kobayashi, Materials Chemistry and Physics 103, 283 (2007). https://doi.org/10.1016/j.matchemphys.2007.02.066.

M. Ekström, A. Thibblin, A. Tjernberg, C. Blomqvist, and S. Jonsson, Surface and Coatings Technology 272, 198 (2015). https://doi.org/10.1016/j.surfcoat.2015.04.005.

F. Zhou, Y. Wang, L. Wang, Z. Cui, and Z. Zhang, Journal of Alloys and Compounds 704, 614 (2017). https://doi.org/10.1016/j.jallcom.2017.02.073.

X. Chen, L. Gu, B. Zou, Y. Wang, and X. Cao, Surface and Coatings Technology 206, 2265 (2012). https://doi.org/10.1016/j.surfcoat.2011.09.076.

S. Nath, I. Manna, and J. D. Majumdar, Journal of Thermal Spray Technology 22, 901 (2013). https://doi.org/10.1007/s11666-013-9937-4.

D. Yang, Y. Gao, H. Liu, and C. Sun, Surface and Coatings Technology 315, 9 (2017). https://doi.org/10.1016/j.surfcoat.2017.01.112.

Q. Yu, A. Rauf, N. Wang, and C. Zhou, Ceramic International 37, 1093 (2011). https://doi.org/10.1016/j.ceramint.2010.11.033.

H. Jamali, R. Mozafarinia, R. Shoja Razavi, R. Ahmadi-Pidani, Ceramics International 38, 6705 (2012). https://doi.org/10.1016/j.ceramint.2012.05.060.

M. Zhai, D. Li, Y. Zhao, X. Zhong, F. Shao, H. Zhao, C. Liu, and S. Tao, Ceramic International 42, 12172 (2016). https://doi.org/10.1016/j.ceramint.2016.04.153.

G.-R. Li, G.-J. Yang, C.-X. Li, and C.-J. Li, Ceramic International 43, 9600 (2017). https://doi.org/10.1016/j.ceramint.2017.04.083.

K. Jiang, S. Liu, and X. Wang, Ceramic International 43, 12633 (2017). https://doi.org/10.1016/j.ceramint.2017.06.142.

R. S. Lima, and B. R. Marple, Materials Science and Engineering A 485, 182 (2008). https://doi.org/10.1016/j.msea.2007.07.082.

G. Di Girolamo, F. Marra, C. Blasi, E. Serra, and T. Valente, Ceramic International 37, 2711 (2011). https://doi.org/10.1016/j.ceramint.2011.04.024.

S. Nath, I. Manna, and J. D. Majumdar, Corrosion Science 88, 10 (2014). https://doi.org/10.1016/j.corsci.2014.06.050.

K. A. Khor, and Y. W. Gu, Thin Solid Films 372, 104 (2000). https://doi.org/10.1016/S0040-6090(00)01024-5.

C. Zhou, N. Wang, and H. Xu, Materials Science and Engineering A 452–453, 569 (2007). https://doi.org/10.1016/j.msea.2006.11.027.

C. Zhou, N. Wang, Z. Wang, S. Gong, and H. Xu, Scripta Materialia 51, 945 (2004). https://doi.org/10.1016/j.scriptamat.2004.07.024.

K. P. Jonnalagadda, R. Eriksson, K. Yuan, X.-H. Li, X. Ji, Y. Yu, and R. L. Peng, Journal of the European Ceramic Society 37, 2889 (2017). https://doi.org/10.1016/j.jeurceramsoc.2017.02.054.

W. R. Chen, X. Wu, B. R. Marple, and P. C. Patnaik, Surface and Coatings Technology 201, 1074 (2006). https://doi.org/10.1016/j.surfcoat.2006.01.023.

E. P. Busso, J. Lin, S. Sakurai, and M. Nakayama, Acta Materialia 49, 1515 (2001).https://doi.org/10.1016/S1359-6454(01)00060-X.

A. Rabiei, and A. G. Evans, Acta Materialia 48, 3963 (2000). https://doi.org/10.1016/S1359-6454(00)00171-3.

J. Wu, H. Guo, L. Zhou, L. Wang, and S. Gong, Journal of Thermal Spray Technology 19, 1186 (2010). https://doi.org/10.1007/s11666-010-9535-7.

P. Carpio, M. D. Salvador, A. Borrell, and E. Sánchez, Ceramic International 43, 4048 (2017). https://doi.org/10.1016/j.ceramint.2016.11.178.

M. G. Gok, and G. Goller, Journal of the European Ceramic Society 37, 2501 (2017). https://doi.org/10.1016/j.jeurceramsoc.2017.02.004.

W. R. Chen, X. Wu, B. R. Marple, and P. C. Patnaik, Surface and Coatings Technology 197, 109 (2005). https://doi.org/10.1016/j.surfcoat.2004.06.027.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Sezavar, A., Sajjadi, S.A., Babakhani, A. et al. Thermal Cyclic Fatigue Behavior of Nanostructured YSZ/NiCrAlY Compositionally Graded Thermal Barrier Coatings. Oxid Met 92, 89–107 (2019). https://doi.org/10.1007/s11085-019-09915-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11085-019-09915-z