Abstract

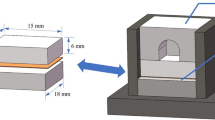

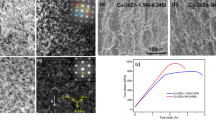

There is a surge of interests in developing newer materials with special properties and many areas are being explored by several groups. We wish to report our findings on the effect of Mn content on the microstructure and tribological behavior of special brass. With the increase of Mn content in the range of 4–10 wt%, the hardness and wear resistance of the special brass were all changed, and the adhesion with abrasion is form the friction behavior, mainly for all brasses. It was observed that the matrix grain size was the smallest, and the hard phase was precipitated the most when the Mn quantity attained the 8 wt% mark. During this period, the brass has the highest hardness and best wear resistance, which results from the grain refinement and load transferring effect of precipitates. It was characterized by SEM, EDS, XRD, TEM, etc., and the results confirmed that the precipitates were Mn5Si3 and its structure was hollow hexagonal prism. The morphology evolution of the hard phase and its growth mechanism have been investigated, analyzed and simulated the nucleation and growth process of the Mn5Si3 phase based on crystallography. The outcomes also showed that the presence of defects on the {0001} faces was the crucial factor for one-dimensional elongated structure of Mn5Si3 phase.

Similar content being viewed by others

References

P.L. Mangonon, The principles of materials selection for engineering design (Prentice Hall, Upper Saddle River, 1999)

C. Vilarinho, J.P. Davim, D. Soares et al., Influence of the chemical composition on the machinability of brasses. J. Mater. Process. Technol. 170(1), 441–447 (2005)

M. Sundberg, R. Sundberg, S. Hogmark et al., Metallographic aspects on wear of special brass. Wear 115(1), 151–165 (1987)

S.G. Mu, J.Y. Dai, Y.R. Wang et al., Study on microstructure and properties of CuZn37Mn3Al2FeSi alloy. Adv. Mater. Res. 287-290, 868–874 (2011)

K. Elleuch, R. Elleuch, R. Mnif et al., Sliding wear transition for the CW614 brass alloy. Tribol. Int. 39(4), 290–296 (2006)

H. Mindivan, H. Çimenoǧlu, E.S. Kayali, Microstructures and wear properties of brass synchroniser rings. Wear 254(5), 532–537 (2003)

A.S. El-Amoush, Investigation of wear properties of hydrogenated tin brass heat exchanger. J. Alloys Compd. 448(1), 257–262 (2008)

H. Li, J. Jie, P. Zhang et al., Study on the formation and precipitation mechanism of Mn5Si3, phase in the MBA-2 brass alloy. Metall. Mater. Trans. A 47(6), 2616–2624 (2016)

Y.S. Sun, G.W. Lorimer, N. Ridley, Microstructure of high-tensile strength brasses containing silicon and manganese. Metall. Trans. A 20(7), 1199–1206 (1989)

A. Waheed, N. Ridley, Microstructure and wear of some high-tensile brasses. J. Mater. Sci. 29(6), 1692–1699 (1994)

H. Li, J. Jie, S. Liu et al., Crystal growth and morphology evolution of D88 (Mn, Fe) 5Si3 phase and its influence on the mechanical and wear properties of brasses. Mater. Sci. Eng. A 704, 45–56 (2017)

Y. Liu, Z. Dong, L. Yu et al., Effects of aging on shape memory and wear resistance of a Fe–Mn–Si-based alloy. J. Mater. Res. 29(23), 2809–2816 (2014)

R. Osoriogalicia, C. Gomezgarcia, M.A. Alcantara et al., Influence of heat treatment and composition variations on microstructure, hardness, and wear resistance of C18000 copper alloy. ISRN Mech. Eng. 2012, 1–6 (2012)

C. Meriç, E. Atík, H. Kaçar, Effect of aging on the abrasive wear properties of AlMgSi1 alloy. Mater. Des. 27(10), 1180–1186 (2006)

Y. Han, K. Ma, L. Li et al., Study on microstructure and mechanical properties of Al–Mg–Si–Cu alloy with high manganese content. Mater. Des. 39, 418–424 (2012)

Y. Li, T.L. Ngai, W. Xia et al., Effects of Mn content on the tribological behaviors of Zn-27% Al-2% Cu alloy. Wear 198(1–2), 129–135 (1996)

D.T. Pierce, J.A. Jiménez, J. Bentley et al., The influence of manganese content on the stacking fault and austenite/ε-martensite interfacial energies in Fe–Mn–(Al–Si) steels investigated by experiment and theory. Acta Mater. 68(2), 238–253 (2014)

L. Ceschini, I. Boromei, A. Morri et al., Microstructure, tensile and fatigue properties of the Al–10%Si–2%Cu alloy with different Fe and Mn content cast under controlled conditions. J. Mater. Process. Technol. 209(15), 5669–5679 (2009)

Laughlin DE, Miao WF, Karabin LM, et al., Effects of Cu and Mn content and processing on precipitation hardening behavior in Al–Mg–Si–Cu alloy 6022. In Proceeding of the 1998 TMS Annual Meeting, vol. 15–19 (1998), pp. 63–79

W.W. Zhang, B. Lin, P. Cheng et al., Effects of Mn content on microstructures and mechanical properties of Al-5.0Cu-0.5Fe alloys prepared by squeeze casting. Trans. Nonferrous Met. Soc. China 23(6), 1525–1531 (2013)

S. Seifeddine, S. Johansson, I.L. Svensson, The influence of cooling rate and manganese content on the β-Al 5 FeSi phase formation and mechanical properties of Al–Si-based alloys. Mater. Sci. Eng., A 490(1–2), 385–390 (2008)

M.A. García-Bernal, R.S. Mishra, R. Verma et al., Hot deformation behavior of friction-stir processed strip-cast 5083 aluminum alloys with different Mn contents. Mater. Sci. Eng., A 534(2), 186–192 (2012)

Y. Birol, The effect of processing and Mn content on the T5 and T6 properties of AA6082 profiles. J. Mater. Process. Technol. 173(1), 84–91 (2006)

X. Cao, N. Saunders, J. Campbell, Effect of iron and manganese contents on convection-free precipitation and sedimentation of primary α-Al(FeMn)Si phase in liquid Al-11.5Si-0.4 Mg alloy. J. Mater. Sci. 39(7), 2303–2314 (2004)

K.A. Darling, A.J. Roberts, L. Armstrong et al., Influence of Mn solute content on grain size reduction and improved strength in mechanically alloyed Al–Mn alloys. Mater. Sci. Eng., A 589(1), 57–65 (2014)

S.A. Khan, Y. Miyashita, Y. Mutoh et al., Influence of Mn content on mechanical properties and fatigue behavior of extruded Mg alloys. Mater. Sci. Eng., A 420(1–2), 315–321 (2006)

J. Zhang, A.T. Alpas, Delamination wear in ductile materials containing second phase particles. Mater. Sci. Eng., A 160(1), 25–35 (1993)

S.E. Broyles, K.R. Anderson, J.R. Groza et al., Creep deformation of dispersion-strengthened copper. Metall. Mater. Trans. A 27(5), 1217–1227 (1996)

H. Zhuo, J. Tang, N. Ye, A novel approach for strengthening Cu–Y2O3, composites by in situ reaction at liquidus temperature. Mater. Sci. Eng., A 584, 1–6 (2013)

H. Li, J. Jie, H. Chen et al., Effect of rotating magnetic field on the microstructure and properties of Cu–Ag–Zr alloy. Mater. Sci. Eng., A 624, 140–147 (2015)

M. Amirat, H. Zaïdi, A. Djamaï et al., Influence of the gas environment on the transferred film of the brass (Cu64Zn36)/steel AISI 1045 couple. Wear 267(1), 433–440 (2009)

M. Ebrahimi, S. Attarilar, F. Djavanroodi et al., Wear properties of brass samples subjected to constrained groove pressing process. Mater. Des. 63(2), 531–537 (2014)

A. Pola, L. Montesano, M. Gelfi et al., Comparison of the sliding wear of a novel Zn alloy with that of two commercial Zn alloys against bearing steel and leaded brass. Wear 368–369, 445–452 (2016)

I. Ebrahimzadeh, F. Ashrafizadeh, A comparative study of surface deformation and quality of brass workpiece in contact with coated dies by pin-on-disc testing. Int. J. Adv. Manuf. Technol. 77(1–4), 609–620 (2015)

K.C. Zhou, J.K. Xiao, L. Zhang et al., Tribological behavior of brass fiber brush against copper, brass, coin-silver and steel. Wear 326–327, 48–57 (2015)

S. Asadikouhanjani, A. Zarebidaki, A. Akbari, The effect of sliding speed and amount of loading on friction and wear behavior of Cu–0.65 wt%Cr alloy. J. Alloys Compd. 486(1), 319–324 (2009)

N. Bouzayeni, M. Kchaou, R. Elleuch, Comparative study of the tribological behavior of brass alloys produced by different manufacturing processes. J. Fail. Anal. Prev. 13(5), 584–594 (2013)

T. Küçükömeroğlu, L. Kara, The friction and wear properties of CuZn39Pb3 alloys under atmospheric and vacuum conditions. Wear 309(1–2), 21–28 (2014)

I. Ebrahimzadeh, F. Ashrafizadeh, High temperature wear and frictional properties of duplex-treated tool steel sliding against a two-phase brass. Ceram. Int. 40(10), 16429–16439 (2014)

G.H. Lander, P.J. Brown, J.B. Forsyth, The antiferromagnetic structure of Mn5Si3. Proc. Phys. Soc. 91(91), 332 (1967)

G. Kappel, G. Fischer, A. Jaéglé, Magnetic investigation of the system Mn5Ge3–Mn5Si3. Physica Status Solidi 34(2), 691–696 (2010)

P.J. Brown, J.B. Forsyth, V. Nunez et al., The low-temperature antiferromagnetic structure of Mn5Si3 revised in the light of neutron polarimetry. J. Phys.: Condens. Matter 41(49), 10025–10036 (1999)

M. Gottschilch, O. Gourdon, J. Persson et al., Study of the antiferromagnetism of Mn5Si3: an inverse magnetocaloriceffect material. J. Mater. Chem. 22(30), 15275–15284 (2012)

M. Ramos Silva, P.J. Brown, J.B. Forsyth, Magnetic moments and magnetic site susceptibilities in Mn5Si3. Light. Res. Off. Light. Res. Symp. 14(37), 117–122 (2002)

P. Hartman, Crystal growth: An introduction. J. Cryst. Growth 22(4), 335–338 (1974)

B. Sadigh, M. Dzugutov, S.R. Elliott, Vacancy ordering and medium-range structure in a simple monatomic liquid. Phys. Rev. B 59(1), 1–4 (1999)

M.Y. Xie, X.F. Li, G.B. Xu et al., Effects of liquid structure transition on solidification by the Newton thermal analysis method. Appl. Phys. A 113(2), 431–437 (2013)

W. Wang, X.F. Bian, J. Qin et al., The atomic-structure changes in Al-16 pct Si alloy above the liquidus. Metall. Mater. Trans. A 31(9), 2163–2168 (2000)

J. Chen, F.Q. Zu, X.F. Li et al., Influence of a liquid structural change on the solidification of the alloy CuSn30. Met. Mater. Int. 14(5), 569–574 (2008)

R.Y. Wang, W.H. Lu, L.M. Hogan, Growth morphology of primary silicon in cast Al–Si alloys and the mechanism of concentric growth. J. Cryst. Growth 207(1), 43–54 (1999)

Q.D. Qin, Y.G. Zhao, W. Zhou et al., Effect of phosphorus on microstructure and growth manner of primary Mg2Si crystal in Mg2Si/Al composite. Mater. Sci. Eng., A 447(1), 186–191 (2007)

C. Li, Y.Y. Wu, H. Li et al., Morphological evolution and growth mechanism of primary Mg2Si phase in Al–MgSi alloys. Acta Mater. 59(3), 1058–1067 (2011)

Acknowledgement

This work was supported by The National Key Research and Development Program of China (2017YFB0306405).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Bie, L., Chen, X., Liu, P. et al. Morphology Evolution of Mn5Si3 Phase and Effect of Mn content on Wear Resistance of Special Brass. Met. Mater. Int. 26, 431–443 (2020). https://doi.org/10.1007/s12540-019-00243-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12540-019-00243-0