Abstract

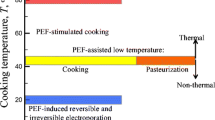

Development of the concept of electroporation opened new perspectives for promising applications in food technology. Treatment of foods with pulsed electric fields (PEFs) allows facilitation of different food transformation operations (extraction, expression, osmotic treatment, drying, and freezing) with minimal energy consumptions and better retention of flavor, color, and preservation of nutritional properties of foods. This work shortly reviews the effects of PEF on the biological cells and food products and gives the examples of PEF-assisted techniques. The PEF protocol, power consumption, and existing small- and large-scale electroporation systems are presented. Some examples of PEF-assisted processing of meat, fish, and fat frying are discussed. The main principles of PEF-assisted cooking and kitchen operations are also discussed. The variants of PEF-assisted non-thermal cooker and PEF/ohmic thermal cooker are presented. It is speculated that PEF allows more homogeneous treatment of foods as compared to the conventional methods of thermal cooking. The PEF-assisted cooking can be faster and more effective for nutrient retention and sensory qualities of foods. Moreover, the PEF treatment can be used for producing the types of the products of fresh/natural quality and new tastes. The recent examples of PEF-assisted processing of meat and fish, assistance of frying, and commercial-scale processing are also presented and discussed.

Similar content being viewed by others

References

Richardson K (2014) Basic cookery for foundation learning. Hodder Education, Carmelite House, London, UK

Crompton RE (1894) 18th meeting: the use of electricity for cooking and heating. RSA J 43:511

Fleming JA (1910) The applications of electric heating. RSA J 59:885

Sater LE (1935) Passing an alternating electric current through food and fruit juices. 1. Design and use of suitable equipment. 2. Cooking food and sterilizing fruit juices. Research bulletin, information systems division. National Agricultural Library N 181:275–312

Sastry S (2008) Ohmic heating and moderate electric field processing. Food Sci Technol Int 14:419–422

Yildiz-Turp G, Sengun IY, Kendirci P, Icier F (2013) Effect of ohmic treatment on quality characteristic of meat: a review. Meat Sci 93:441–448

Vollmer M (2004) Physics of the microwave oven. Phys Educ 39:74–81

Kurti N, This-Benckhard H (1994) Chemistry and physics in the kitchen. Sci Am 270:44–51

This H (2011) Molecular gastronomy in France. J Culinary Sci Technol 9:140–149

Liberman V (2014) Molecular gastronomy. In: Thompson PB, Kaplan DM (eds) Encyclopedia of food and agricultural ethics. Springer, Dordrecht, pp 1382–1387

Der Linden E, McClements DJ, Ubbink J (2008) Molecular gastronomy: a food fad or an interface for science-based cooking? Food Biophys 3:246–254

Barham P, Skibsted LH, Bredie WLP et al (2010) Molecular gastronomy: a new emerging scientific discipline. Chem Rev 110:2313–2365

Barham P (2013) Physics in the kitchen. Flavour 2:1–4

Vilgis TA (2015) Soft matter food physics—the physics of food and cooking. Rep Prog Phys 78:124602

Vega C, Ubbink J (2008) Molecular gastronomy: a food fad or science supporting innovative cuisine? Trends Food Sci Technol 19:372–382

Stämpfli R (1958) Reversible electrical breakdown of the excitable membrane of a Ranvier node. Annals of Academia Brasileira de Ciencias 30:57–63

Weaver JC, Chizmadzhev YA (1996) Theory of electroporation: a review. Bioelectrochem Bioenerg 41:135–160

Knorr D, Geulen M, Grahl T, Sitzmann W (1994) Food application of high electric field pulses. Trends Food Sci Technol 5:71–75. doi:10.1016/0924-2244(94)90240-2

Vorobiev EI, Lebovka NI Electrotechnologies for extraction from food plants and biomaterials. Springer, New York

Vorobiev E, Lebovka N (2010) Enhanced extraction from solid foods and biosuspensions by pulsed electrical energy. Food Eng Rev 2:95–108

Toepfl S, Heinz V, Knorr D (2005) Effect of high-intensity electric field pulses on solid foods. In: Sun D-W (ed) Overview of pulsed electric field processing for food. Academic Press, London, pp 69–97

Toepfl S (2012) Pulsed electric field food processing: industrial equipment design and commercial applications. Stewart Postharvest Rev 8:1–7. doi:10.2212/spr.2012.2.4

Toepfl S, Siemer C, Saldana-Navarro G, Heinz V (2014) Overview of pulsed electric fields processing for food. In: Sun D-W (ed) Emerging Technologies for Food Processing. Academic Press, London, pp 93–114

Mahnič-Kalamiza S, Vorobiev E, Miklavčič D (2014) Electroporation in food processing and biorefinery. J Membr Biol 247:1279–1304

Kotnik T, Frey W, Sack M et al (2015) Electroporation-based applications in biotechnology. Trends Biotechnol 33:480–488. doi:10.1016/j.tibtech.2015.06.002

Barbosa-Cánovas GV, Sepúlveda D (2005) Present status and the future of PEF technology. In: Barbosa-Cánovas GV, Tapia MS, Cano MP (eds) Novel food processing technologies. CRC Press, Boca Raton, pp 1–44

Barba FJ, Parniakov O, Pereira SA et al (2015) Current applications and new opportunities for the use of pulsed electric fields in food science and industry. Food Res Int 77:773–798

Schwan HP (1957) Advances in biological and medical physics. In: Tobias A (ed) Lawrence JH. Academic Press, New York, pp 147–209

Tsong TY (1991) Electroporation of cell membranes. Biophys J 60:297–306. doi:10.1016/S0006-3495(91)82054-9

Coster HGL, Zimmermann U (1975) The mechanism of electrical breakdown in the membranes of Valonia utricularis. J Membr Biol 22:73–90. doi:10.1007/BF01868164

Fincan M, Dejmek P (2002) In situ visualization of the effect of a pulsed electric field on plant tissue. J Food Eng 55:223–230

Ho SY, Mittal GS (1996) Electroporation of cell membranes: a review. Crit Rev Biotechnol 16:349–362

Chen C, Smye SW, Robinson MP, Evans JA (2006) Membrane electroporation theories: a review. Med Biol Eng Comput 44:5–14

Dimitrov DS, Sowers AE (1990) Membrane electroporaton—fast molecular exchange by electroosmosis. Biochimica et Biophysica Acta (BBA)-Biomembranes 1022:381–392

Coster HGL (2003) The physics of cell membranes. J Biol Phys 29:363–399

Lebovka NI, Bazhal MI, Vorobiev E (2002) Estimation of characteristic damage time of food materials in pulsed-electric fields. J Food Eng 54:337–346

Bazhal M, Lebovka N, Vorobiev E (2003) Optimisation of pulsed electric field strength for electroplasmolysis of vegetable tissues. Biosyst Eng 86(3):339–345

Zhang Q, Monsalve-González A, Qin B-L et al (1994) Inactivation of Saccharomyces cerevisiae in apple juice by square-wave and exponential-decay pulsed electric fields. J Food Process Eng 17:469–478. doi:10.1111/j.1745-4530.1994.tb00350.x

Blahovec J, Kouřím P, Kindl M (2015) Low-temperature carrot cooking supported by pulsed electric field—DMA and DETA thermal analysis. Food Bioprocess Technol 8:2027–2035. doi:10.1007/s11947-015-1554-4

Campbell D, Harper J, Natham V, et al (2008) A compact high voltage nanosecond pulse generator. In: Proceedings of ESA (Electrostatics Society of America) Annual Meeting on Electrostatics, Paper H3, 12 pp. pp 1–12

Flisar K, Meglic SH, Morelj J et al (2014) Testing a prototype pulse generator for a continuous flow system and its use for E. coli inactivation and microalgae lipid extraction. Bioelectrochemistry 100:44–51. doi:10.1016/j.bioelechem.2014.03.008

Wouters PC, Smelt JPPM (1997) Inactivation of microorganisms with pulsed electric fields: potential for food preservation. Food Biotechnol 11:193–229. doi:10.1080/08905439709549933

Qin B-L, Zhang Q, Barbosa-Cánovas GV et al (1994) Inactivation of microorganisms by pulsed electric fields of different voltage waveforms. IEEE Trans Dielectr Electr Insul 1:1047–1057. doi:10.1109/94.368658

Ben Ammar J (2011) Etude de l’effet des champs electriques pulses sur la congelation des produits vegetaux, PhD Thesis, Compiegne: Universite de Technologie de Compiegne, France. PhD Thesis, Compiegne: Universite de Technologie de Compiegne, France

De Vito F, Ferrari G, Lebovka NI, Shynkaryk NV, Vorobiev E (2008) Pulse duration and efficiency of soft cellular tissue disintegration by pulsed electric fields. Food Bioprocess Technol 1:307–313

Lebovka NI, Bazhal MI, Vorobiev E (2001) Pulsed electric field breakage of cellular tissues: visualisation of percolative properties. Innovative Food Sci Emerg Technol 2:113–125. doi:10.1016/S1466-8564(01)00024-8

Asavasanti S, Ristenpart W, Stroeve P, Barrett DM (2011) Permeabilization of plant tissues by monopolar pulsed electric fields: effect of frequency. J Food Sci 76(1):E96–E111

Asavasanti S, Stroeve P, Barrett DM et al (2012) Enhanced electroporation in plant tissues via low frequency pulsed electric fields: influence of cytoplasmic streaming. Biotechnol Prog 28:445–453

Evrendilek GA, Zhang QH (2005) Effects of pulse polarity and pulse delaying time on pulsed electric fields-induced pasteurization of E. coli O157:H7. J Food Eng 68:271–276

Toepfl S (2006) Pulsed electric fields (PEF) for permeabilization of cell membranes in food- and bioprocessing. Applications, process and equipment design and cost analysis. PhD Thesis, Berlin University of Technology, Germany

Ben Ammar J, Lanoiselle J-L, Lebovka NI et al (2011) Effect of a pulsed electric field and osmotic treatment on freezing of potato tissue. Food Biophys 5(3):247–254. doi:10.1111/j.1750-3841.2010.01893.x

Lebovka N, Vorobiev E (2011) Food and biomaterials processing assisted by electroporation. In: G PA, Miklavcic D, Markov MS (eds) Advanced electroporation techniques in biology and medicine. CRC Press, pp 463–490

Cortese P, Dellacasa G, Gemme R et al (2011) A pulsed electric field (PEF) bench static system to study bacteria inactivation. Nucl Phys B Proc Suppl 215:162–164. doi:10.1016/j.nuclphysbps.2011.03.165

Pourzaki A, Mirzaee H (2008) Pulsed electric field generators in food processing. In: 18-th National Congress on Food Technology in Mashhad (Iran). pp 1–7

BTX/Harvard Apparatus (2016) Electroporation & electrofusion products, http://www.btxonline.com.

Eppendorf Multiporator® System (2016) Eppendorf Multiporator® System, Multitalent for transfection and cell fusion http://www.eppendorf.com.

Bio-Rad (2016) Electroporation System http://www.bio-rad.com.

Mohamed MEA, Eissa AHA (2012) Structure and function of food engineering. In: Eissa AHA (ed). Academic Press, London, pp 275–306

Dunn J (1996) Pulsed light and pulsed electric field for foods and eggs. Poult Sci 75:1133–1136

Diversified Technologies I (2016) Food and wastewater processing, http://www.divtecs.com/food-and-wastewater-processing.

Kempkes MA, Tokusoglu O (2015) Improving food quality with novel food processing technologies. In: Tokusoglu O, Swanson BG (eds). CRC Press, Taylor & Francis LLC, pp 427–453

Kempkes M, Roth I, Reinhardt N (2012) Enhancing industrial processes by pulsed electric fields. In: Proceedings of Euro-Asian Pulsed Power Conference. Karlsruhe, Germany, pp 1–4

Kempkes M, Simpson R, Roth I (2016) Removing barriers to commercialization of PEF systems and processes. In: Proceedings of 3rd School on Pulsed Electric Field Processing of Food. Institute of Food and Health, University College Dublin, Dublin, pp 1–6

DIL/ELEA (2016) Pulsed electric field technology. The Science of Food-Physics™, http://www.elea-technology.com.

SteriBeam Systems GmbH (2016) SteriBeam Systems GmbH, Fully-automatic bench-top PEF R&D sterilization systems, http://www.steribeam.com.

KEA-TEC GmbH (2016) Industrial electroporation plants, http://www.kea-tec.de.

Haferkamp R (2016) BLIZZAR made by KEA-TEC GmbH, http://www.blizzar.eu.

CoolWave Processing (2016) How does PurePulse work? http://www.purepulse.eu/.

Arc Aroma Pures (2016) Arc Aroma Pures—CEPT®—closed environment PEF treatment, http://www.arcaromapure.se.

ScandiNova Systems AB (2016) Excellence in pulsed power, http://www.scandinovasystems.com.

EnergyPulse Systems Lda (2016) EPULSUS®, high performance pulse generators, http://energypulsesystems.pt.

Basis EP (2016) Energies pulsées, http://www.arcaromapure.se/.

Pulsemaster (2016) Pulsed electric field processing for the food industry, https://www.pulsemaster.us.

Clark JP (2006) Pulsed electric field processing. Food Technol 60:66–67

Personius CJ, Sharp PF (1938) Permeability of potato-tuber tissue as influenced by heat. J Food Sci 3:525–538. doi:10.1111/j.1365-2621.1938.tb17088.x

Blahovec J, Kouřím P (2016) Combined mechanical (DMA) and dielectric (DETA) thermal analysis of carrot at temperatures 30–90 °C. J Food Eng 168:245–250. doi:10.1016/j.jfoodeng.2015.07.044

Lebovka NI, Praporscic I, Vorobiev E (2004) Effect of moderate thermal and pulsed electric field treatments on textural properties of carrots, potatoes and apples. Innov Food Sci Emerg Technol 5:9–16

Vorobiev E, Lebovka N (2011) Pulse electric field-assisted extraction. In: Lebovka N, Vorobiev E, Chemat F (eds) Enhancing Extraction Processes in the Food Industry. CRC Press, Taylor & Francis LLC, pp 25–83

Bazhal MI, Lebovka NI, Vorobiev E (2001) Pulsed electric field treatment of apple tissue during compression for juice extraction. J Food Eng 50:129–139

Praporscic I, Shynkaryk MV, Lebovka NI, Vorobiev E (2007) Analysis of juice colour and dry matter content during pulsed electric field enhanced expression of soft plant tissues. J Food Eng 79:662–670

Shynkaryk MV, Lebovka NI, Vorobiev E (2008) Pulsed electric fields and temperature effects on drying and rehydration of red beetroots. Dry Technol 26:695–704

Jalte M, Lanoiselle J-L, Lebovka NI, Vorobiev E (2009) Freezing of potato tissue pre-treated by pulsed electric fields. LWT Food Sci Technol 42:576–580

Wiktor A, Schulz M, Voigt E et al (2015) The effect of pulsed electric field treatment on immersion freezing, thawing and selected properties of apple tissue. J Food Eng 146:8–16

Phoon PY, Galindo FG, Vicente A, Dejmek P (2008) Pulsed electric field in combination with vacuum impregnation with trehalose improves the freezing tolerance of spinach leaves. J Food Eng 88:144–148

Parniakov O, Bals O, Lebovka N, Vorobiev E (2016) Pulsed electric field assisted vacuum freeze-drying of apple tissue. Innovative Food Sci Emerg Technol 35:52–57

Donsi F, Ferrari G, Pataro G (2010) Applications of pulsed electric field treatments for the enhancement of mass transfer from vegetable tissue. Food Eng Rev 2:109–130

Shayanfar S, Chauhan OP, Toepfl S, Heinz V (2013) The interaction of pulsed electric fields and texturizing—antifreezing agents in quality retention of defrosted potato strips. Int J Food Sci Technol 48:1289–1295

Shayanfar S, Chauhan OP, Toepfl S, Heinz V (2014) Pulsed electric field treatment prior to freezing carrot discs significantly maintains their initial quality parameters after thawing. Int J Food Sci Technol 49:1224–1230

Parniakov O, Lebovka NI, Bals O, Vorobiev E (2015) Effect of electric field and osmotic pre-treatments on quality of apples after freezing-thawing. Innovative Food Sci Emerg Technol 29:23–30

Jaeger H, Janositz A, Knorr D (2010) The Maillard reaction and its control during food processing. The potential of emerging technologies [la reaction de Maillard et son controle pendant la fabrication des aliments. Le potentiel des nouvelles technologies]. Pathol Biol 58:207–213

Sack M, Sigler J, Frenzel S et al (2010) Research on industrial-scale electroporation devices fostering the extraction of substances from biological tissue. Food Eng Rev 2:147–156. doi:10.1007/s12393-010-9017-1

IXL Netherlands B.V. (2016) The Nutri-Pulse® “cooks” with electric pulses, www.innovation-xl.com.

Erfinder, Van Oord G, Roelofs JTM(2016) Low field strength PEF cooking, Patent EU WO 2016008868 A1.

Arroyo C, Eslami S, Brunton NP et al (2015) An assessment of the impact of pulsed electric fields processing factors on oxidation, color, texture, and sensory attributes of turkey breast meat. Poult Sci pev097:1–8

Gudmundsson M, Hafsteinsson H (2001) Effect of electric field pulses on microstructure of muscle foods and roes. Trends Food Sci Technol 12:122–128. doi:10.1016/S0924-2244(01)00068-1

Toepfl S, Heinz V (2007) Application of pulsed electric fields to improve mass transfer in dry cured meat products. Fleischwirtschaft Int J Meat Prod Meat Process 22:62–64

O’Dowd LP, Arimi JM, Noci F et al (2013) An assessment of the effect of pulsed electrical fields on tenderness and selected quality attributes of post rigour beef muscle. Meat Sci 93:303–309. doi:10.1016/j.meatsci.2012.09.010

McDonnell CK, Allen P, Chardonnereau FS, et al (2014) The use of pulsed electric fields for accelerating the salting of pork. LWT—food science and technology 59:1054–1060. doi: 10.1016/j.lwt.2014.05.053

Arroyo C, Lascorz D, O’Dowd L et al (2015) Effect of pulsed electric field treatments at various stages during conditioning on quality attributes of beef longissimus thoracis et lumborum muscle. Meat Sci 99:52–59. doi:10.1016/j.meatsci.2014.08.004

Bekhit AE-DA, Hopkins D (2014) Enhancement of meat quality by pulsed electric field application. Project A.MQA.0005. Level 1, 40 Mount Street, North Sydney NSW 2060

Bekhit AE-DA, Carne A, Ha M, Franks P (2014) Physical interventions to manipulate texture and tenderness of fresh meat: a review. Int J Food Prop 17:433–453. doi:10.1080/10942912.2011.642442

Faridnia F, Bekhit AE-DA, Niven B, Oey I (2014) Impact of pulsed electric fields and post-mortem vacuum ageing on beef longissimus thoracis muscles. Int J Food Sci Technol 49:2339–2347. doi:10.1111/ijfs.12532

Suwandy V, Carne A, Van de Ven R et al (2015) Effect of pulsed electric field on the proteolysis of cold boned beef M. longissimus lumborum and M. semimembranosus. Meat Sci 100:222–226. doi:10.1016/j.meatsci.2014.10.011

Faridnia F (2015) The impact of pulsed electric field (PEF) processing on solid food materials. PhD Thesis, University of Otago, New Zealand

Faridnia F, Ma QL, Bremer PJ et al (2015) Effect of freezing as pre-treatment prior to pulsed electric field processing on quality traits of beef muscles. Innovative Food Sci Emerg Technol 29:31–40

Janositz A, Noack A-K, Knorr D (2011) Pulsed electric fields and their impact on the diffusion characteristics of potato slices. LWT-Food Sci Technol 44:1939–1945

Ignat A, Manzocco L, Brunton NP et al (2015) The effect of pulsed electric field pre-treatments prior to deep-fat frying on quality aspects of potato fries. Innovative Food Sci Emerg Technol 29:65–69

Totosaus A, De Lourdes Pérez-Chabela M (2004) Poultry: poultry nuggets. In: Smith JS, Hui YH (eds) Food Processing: Principles and Applications. Blackwell Publishing, pp 433–438

Garret RH, Grisham CM (2010) Biochemistry, 4th edn. Brooks/Cole, Cengage Learning, Boston

Buckow R, Ng S, Toepfl S (2013) Pulsed electric field processing of orange juice: a review on microbial, enzymatic, nutritional, and sensory quality and stability. Compr Rev Food Sci Food Saf 12:455–467

Lelieveld H, Mastwijk H, Oord G, et al (2011) Cooking in seconds with PEF. More nutrients—better taste, http://www.innova-uy.info.

Lebovka NI, Praporscic I, Ghnimi S, Vorobiev E (2005) Does electroporation occur during the ohmic heating of food? J Food Sci 70:E308–E311

Goettsch C, Roelofs H (2014) Stew cooked in minutes. The sustainable breakthrough in food preparation. Voedingsindustrie 2:8–9

Timmermans RAH, Mastwijk HC, Knol JJ et al (2011) Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice. Part I: impact on overall quality attributes. Innovative Food Sci Emerg Technol 12:235–243

Vervoort L, Der Plancken I, Grauwet T et al (2011) Comparing equivalent thermal, high pressure and pulsed electric field processes for mild pasteurization of orange juice: part II: impact on specific chemical and biochemical quality parameters. Innovative Food Sci Emerg Technol 12:466–477

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

In this review, principles of ethical and professional conduct have been followed. This study does not involve research on human participants and/or animals.

Conflict of Interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Blahovec, J., Vorobiev, E. & Lebovka, N. Pulsed Electric Fields Pretreatments for the Cooking of Foods. Food Eng Rev 9, 71–81 (2017). https://doi.org/10.1007/s12393-017-9160-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12393-017-9160-z