Abstract

Iron molybdate/molybdenum oxide catalysts with varying content of Mo (Mo/Fe = 1.6 and 2.0) were synthesized by a mild hydrothermal method and structurally characterized by XRD, XPS, Raman spectroscopy, SEM–EDX, BET and ICP-OES. The stability of the prepared catalysts in selective oxidation of methanol to formaldehyde was investigated by catalytic activity measurements for up to 100 h on stream in a laboratory fixed-bed reactor (5% MeOH, 10% O2 in N2, temp. = 380–407 °C). Excess MoO3 present in the catalyst volatilized under reaction conditions, which lead to an initial loss of activity. Interestingly, the structure of the excess MoO3 significantly affected the stability of the catalyst. By using low temperature hydrothermal synthesis, catalysts with the thermodynamically metastable hexagonal h-MoO3 phase was synthesized, which yielded relatively large crystals (2–10 µm), with correspondingly low surface area to volume ratio. The rate of volatilization of MoO3 from these crystals was comparatively low, which stabilized the catalysts. It was furthermore shown that heat-treatment of a spent catalyst, subject to significant depletion of MoO3, reactivated the catalyst, likely due to migration of Mo from the bulk of the iron molybdate crystals to the surface region.

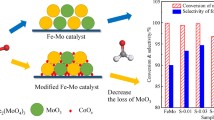

Graphical Abstract

Fe2(MoO4)3/MoO3 catalysts for selective oxidation of methanol were synthesized by hydrothermal synthesis forming large hexagonal-MoO3 crystals. Significantly lower rate of catalyst deactivation due to volatilization of MoO3 under reaction conditions was observed for the large h-MoO3 compared to smaller crystals of thermodynamically stable α-MoO3.

Ambient pressure: FeMo_2.0α is adapted from [24]

Data adapted from Raun et al. [24]

Similar content being viewed by others

References

Merchant Research & Consulting ltd (2016) World Formaldehyde Production to Exceed 52 Mln Tonnes in 2017

IHS Chemical (2013) IHS analysis report Forecast: global formaldehyde market demand after five years

Bahmanpour AM, Hoadley A, Tanksale A (2014) Critical review and exergy analysis of formaldehyde production processes. Rev Chem Eng. https://doi.org/10.1515/revce-2014-0022

Magnusson A, Thevenin P (2018) In: Informally speaking (newsletter from Formox), winter 2017/2018

Günther R, Disteldorf W, Gamer AO, Hilt A (2012) Ullmann’s encyclopedia of industrial chemistry. Weinheim Chapter 4: Chapter 4

Ivanov KI, Dimitrov DY (2010) Deactivation of an industrial iron-molybdate catalyst for methanol oxidation. Catal Today 154:250–255. https://doi.org/10.1016/j.cattod.2010.03.051

Soares APV, Portela MF, Kiennemann A (2005) Methanol selective oxidation to formaldehyde over iron-molybdate catalysts. Catal Rev 47:125–174. https://doi.org/10.1081/CR-200049088

Söderhjelm E, House MP, Cruise N et al (2008) On the synergy effect in MoO3–Fe2(MoO4)3 catalysts for methanol oxidation to formaldehyde. Top Catal 50:145–155. https://doi.org/10.1007/s11244-008-9112-1

Bowker M, Carley AF, House M (2008) Contrasting the behaviour of MoO3 and MoO2 for the oxidation of methanol. Catal Lett 120:34–39. https://doi.org/10.1007/s10562-007-9255-x

Yeo BR, Pudge GJF, Bugler KG et al (2016) The surface of iron molybdate catalysts used for the selective oxidation of methanol. Surf Sci 648:163–169. https://doi.org/10.1016/j.susc.2015.11.010

Brookes C, Wells PP, Dimitratos N et al (2014) The nature of the molybdenum surface in iron molybdate. the active phase in selective methanol oxidation. J Phys Chem C 118:26155–26161. https://doi.org/10.1021/jp5081753

Bowker M, Brookes C, Carley AF et al (2013) Evolution of active catalysts for the selective oxidative dehydrogenation of methanol on Fe2O3 surface doped with Mo oxide. Phys Chem Chem Phys 15:11988–12003. https://doi.org/10.1039/c3cp50399b

Bowker M, House M, Alshehri A et al (2015) Selectivity determinants for dual function catalysts: applied to methanol selective oxidation on iron molybdate. Catal Struct React 1:95–100. https://doi.org/10.1179/2055075815Y.0000000002

Rellán-Piñeiro M, López N (2015) The active molybdenum oxide phase in the methanol oxidation to formaldehyde (Formox process): a DFT study. Chemsuschem 8:2231–2239. https://doi.org/10.1002/cssc.201500315

Popov BI, Bibin VN, Boreskov GK (1976) Study of an iron-molybfate oxide catalyst for oxidation of methanol to formaldehyde. Kinet Catal 17:322–327

Andersson A, Hernelind M, Augustsson O (2006) A study of the ageing and deactivation phenomena occurring during operation of an iron molybdate catalyst in formaldehyde production. Catal Today 112:40–44. https://doi.org/10.1016/j.cattod.2005.11.052

Pernicone N (1991) Deactivation of Fe–Mo oxide catalyst in industrial plant and simulation tests on laboratory scale. Catal Today 11:85–91. https://doi.org/10.1016/0920-5861(91)87009-C

Xu Q, Jia G, Zhang J et al (2008) Surface phase composition of iron molybdate catalysts studied by UV Raman spectroscopy. J Phys Chem C 112:9387–9393. https://doi.org/10.1021/jp800359p

Vieira Soares AP, Farinha Portela M, Kiennemann A (2005) Methanol selective oxidation to formaldehyde over iron-molybdate catalysts. Catal Rev Sci Eng 47:125–174

Lohbeck K, Haferkorn H, Fuhrmann W, Fedtke N (2005) Manganese and manganese alloys. Ullmann’s Encycl Ind Chem. https://doi.org/10.1002/14356007.a16

McCarron EMI (1986) β-MoO3: a metastable analogue of WO3. J Chem Soc, Chem Commun 101:336–338

Dhage SR, Hassan MS, Yang OB (2009) Low temperature fabrication of hexagon shaped h-MoO3 nanorods and its phase transformation. Mater Chem Phys 114:511–514. https://doi.org/10.1016/j.matchemphys.2008.10.076

Hu H, Deng C, Xu J et al (2015) Metastable h -MoO 3 and stable α-MoO3 microstructures: controllable synthesis, growth mechanism and their enhanced photocatalytic activity. J Exp Nanosci 10:1336–1346. https://doi.org/10.1080/17458080.2015.1012654

Raun KV, Lundegaard LF, Chevallier J et al (2018) Deactivation behavior of an iron-molybdate catalyst during selective oxidation of methanol to formaldehyde. Catal Sci Technol 8:4626–4637. https://doi.org/10.1039/C8CY01109E

Gaur A, Schumann M, Raun KV et al (2019) Operando XAS/XRD and raman spectroscopic study of structural changes of the iron molybdate catalyst during selective oxidation of methanol. ChemCatChem. https://doi.org/10.1002/cctc.201901025

Beale AM, Jacques SDM, Sacaliuc-Parvalescu E et al (2009) An iron molybdate catalyst for methanol to formaldehyde conversion prepared by a hydrothermal method and its characterization. Appl Catal A Gen 363:143–152. https://doi.org/10.1016/j.apcata.2009.05.008

Høj M, Kessler T, Beato P et al (2014) Structure, activity and kinetics of supported molybdenum oxide and mixed molybdenum-vanadium oxide catalysts prepared by flame spray pyrolysis for propane OHD. Appl Catal A Gen 472:29–38. https://doi.org/10.1016/j.apcata.2013.11.027

Van Leeuwen ME (1994) Derivation of Stockmayer potential parameters. Fluid Phase Equilib 99:1–18

Tee LS, Gotoh S, Stewart WE (1966) Molecular parameters for normal fluids. Lennard–Jones 12–6 potential. Ind Eng Chem Fundam 5:356–363. https://doi.org/10.1021/i160019a011

Mourits FM, Rummens FHA (1977) A critical evaluation of Lennard–Jones and Stockmayer potential parameters and of some correlation methods. Can J Chem 55:3007–3020. https://doi.org/10.1139/v77-418

Coelho AA (2018) TOPAS and TOPAS-academic: an optimization program integrating computer algebra and crystallographic objects written in C++. J Appl Cryst 51:210–218

Braz CG, Mendes A, Rocha J et al (2019) Model of an industrial multitubular reactor for methanol to formaldehyde oxidation in the presence of catalyst deactivation. Chem Eng Sci 195:347–355. https://doi.org/10.1016/J.CES.2018.09.033

Drăgan S, Kulic I (2016) A macrokinetic study of the oxidation of methanol to formaldehyde on Fe2O3–MoO3 oxide catalyst. Stud Univ Babes-Bolyai, Chem, p 61

Lunk HJ, Hartl H, Hartl MA et al (2010) “Hexagonal molybdenum trioxide”—known for 100 years and still a fount of new discoveries. Inorg Chem 49:9400–9408. https://doi.org/10.1021/ic101103g

Schuh K, Kleist W, Høj M et al (2014) Selective oxidation of propylene to acrolein by hydrothermally synthesized bismuth molybdates. Appl Catal A Gen 482:145–156. https://doi.org/10.1016/j.apcata.2014.05.038

Bowker M, Holroyd R, House M et al (2008) The selective oxidation of methanol on iron molybdate catalysts. Top Catal 48:158–165. https://doi.org/10.1007/s11244-008-9058-3

Peláez R, Marín P, Ordóñez S (2016) Synthesis of formaldehyde from dimethyl ether on alumina-supported molybdenum oxide catalyst. Appl Catal A Gen 527:137–145. https://doi.org/10.1016/j.apcata.2016.09.002

Brookes C, Wells PP, Cibin G et al (2014) Molybdenum oxide on Fe2O3 core–shell catalysts: probing the nature of the structural motifs responsible for methanol oxidation catalysis. ACS Catal 4:243–250. https://doi.org/10.1021/cs400683e

Fagherazzi G, Pernicone N (1970) Structural study of a methanol oxidation catalyst. J Catal 16:321–325. https://doi.org/10.1016/0021-9517(70)90228-9

Acknowledgements

This work is a collaboration between the CHEC research center at The Department of Chemical and Biochemical Engineering at Technical University of Denmark (DTU), Karlsruhe Institute of Technology (KIT) and Haldor Topsøe A/S. We thank the Independent Research Fund Denmark for the financial support (DFF—4184-00336).

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

10562_2019_3034_MOESM1_ESM.docx

Supplementary material 1 Activity, selectivity and carbon mole balance measurements, reference Raman spectra, Arrhenius plots, SEM images of sample FeMo_2.0h and FeMo_2.0α, XPS spectra and operando Raman spectra for the FeMo_2.0h sample. (DOCX 1822 kb)

Rights and permissions

About this article

Cite this article

Raun, K.V., Lundegaard, L.F., Beato, P. et al. Stability of Iron-Molybdate Catalysts for Selective Oxidation of Methanol to Formaldehyde: Influence of Preparation Method. Catal Lett 150, 1434–1444 (2020). https://doi.org/10.1007/s10562-019-03034-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-03034-9