Abstract

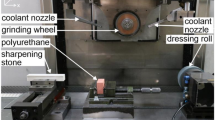

Theoretical and experimental investigations have provided a deep insight into the process of diamond dressing of vitrified grinding wheels under the mechanisms of micro- or macrofracture of abrasive grits. This permits determining the process parameters dressing in coarse and finish grinding operations. The authors propose equations for finding the depth of dressing for various types of have been proposed for different wheel working layer states.

Similar content being viewed by others

References

Kolomiyets, V.V., Polupan, B.I., and Khimach, O.V., Almaznyi instrument fasonnogo profilya (Profile Diamond Tools), Kyiv: Naukova Dumka, 1992.

Korolev, A.V. and Bereznyak, R.A., Progressivnye protsessy pravki shlifoval’nykh krugov (Advanced Dressing Processes for Grinding Wheels), Saratov: Izd. Saratov. Univers., 1984.

Kremnev, G.P., Nitsa, A.N., and Sokolov, V.F., Increasing effectiveness of grinding by dressing the abrasive grinding wheels, Inform. Tekhnol. Osviti, Nautsi ta Vyrobn., 2015, no. 3(8), pp. 233–238.

Malyshev, V.I., Producing a grinding wheel working surface by ultrasonic dressing, Vekt. Nauk. Tolyut. Gos. Univers., 2010, no. 2, pp. 40–43.

Pahlitzsch, G., Bedeutung des Schneidflächenzustandes von Schleifscheiben für den Schleifprozeß, Industrie Dia-manten Rundschau, 1974, no. 3, pp. 158–168.

Sheiko, M.N., Lavrinova, E.S., and Chepovetskii, I.Kh., The influence of diamond roller dressing of grinding wheels on the machined surface roughness in plunge grinding, Sverkhtverdye Materialy, 1992, no. 1, pp. 38–39 [J. Superhard Mater., 1992, no. 1].

Schwarz, K.E., Zerspanungsvogange und Schleifergebnis beim Abrichten von Grinding, J. Manufacturing Sci. Eng., 2001, vol. 123, pp. 319–324.

Lurie, G.B., Shlifovanie metallov (Metal Grinding), Moscow: Mashinostroenie, 1967.

Shakhbazov, Ya.O., Keruvannya robochoyu poverkhneyu shlifuval’nykh krugiv (Controlling the Grinding Wheel Working Surface), Lviv: Feniks, 1998.

Author information

Authors and Affiliations

Corresponding author

Additional information

Ukrainian Text © The Author(s), 2019, published in Sverkhtverdye Materialy, 2019, Vol. 41, No. 4, pp. 76–82.

About this article

Cite this article

Shakhbazov, Y.O., Shyrokov, V.V. & Fedorovych, V.O. Specifying the Process Parameters for Diamond Dressing of Grinding Wheels. J. Superhard Mater. 41, 272–277 (2019). https://doi.org/10.3103/S1063457619040075

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457619040075