Abstract

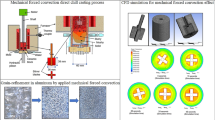

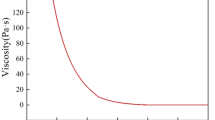

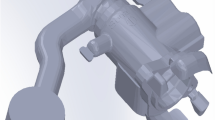

The continuing quest for aluminum castings with fewer defects has aroused the interest in rheological high-pressure die casting (RHPDC). A new machine, stirring integrated transfer-heat (SIT) device, based on the mechanical stirring and enhanced cooling for semisolid slurry preparation was proposed to produce the thin-walled communication shell part by RHPDC process. The influence of SIT process characteristics on the microstructure was studied. The microstructure of SIT-RHPDC shell part in different locations was investigated. Combined with simulation, the flow characteristics and the temperature field change in the melt under the stirring-only process and different stirring with internal water-cooling conditions were studied to get a better understanding of the nucleation, grain growth and solidification behavior. Under the dual action of agitation and heat dissipation in SIT device, the fluid convection has changed the temperature field of the melt significantly. The temperature field of the melt becomes relatively uniform from a great temperature gradient and the continuous cooling rate is increased to 5 °C/s. In the same time, the slurry has a greater supercooling degree, and flows more evenly in the filling process. The experimental results indicate that compared with microstructure of an HPDC component, the microstructure at different locations of SIT-RHPDC part is composed of refined rosiness and nearly spherical particles.

Similar content being viewed by others

Data Availability

We confirm that the manuscript has been read and approved by all named authors and that there are no other persons who satisfied the criteria for authorship but are not listed. We further confirm that the order of authors listed in the manuscript has been approved by all of us. We confirm that we have given due consideration to the protection of intellectual property associated with this work and that there are no impediments to publication, including the timing of publication, with respect to intellectual property. In doing so, we confirm that we have followed the regulations of our institutions concerning intellectual property. All the data in this article are original. The simulations are provided by Flow-3D.

References

Y.D. Sui, Q.D. Wang, B. Ye, L. Zhang, H.Y. Jiang, W.J. Ding, Effect of solidification sequence on the microstructure and mechanical properties of die-cast Al–11Si–2Cu–Fe alloy. J. Alloys Compd. 649, 679–686 (2015)

A. Heinz, A. Haszler, C. Keidel, S. Moldenhauer, R. Benedictus, W.S. Miller, Recent development in aluminium alloys for aerospace applications. Mater. Sci. Eng. A 280, 102–107 (2000)

W.S. Miller, L. Zhuang, J. Bottema, A.J. Wittebrood, P. De Smet, A. Haszler, Recent development in aluminum alloys for the automotive industry. Mater. Sci. Eng. A 280, 37–49 (2000)

C.K. Jin, C.H. Jang, C.G. Kang, Die design method for thin plates by indirect rheo-casting process and effect of die cavity friction and punch speed on microstructures and mechanical properties. J. Mater. Process. Technol. 224, 156–168 (2015)

I. Outmani, L. Fouilland-Paille, J. Isselin, M.E. Mansori, Effect of Si, Cu and processing parameters on Al–Si–Cu HPDC castings. J. Mater. Process. Technol. 249, 559–569 (2017)

X.G. Hu, Q. Zhu, S.P. Midson, H.V. Atkinson, H.B. Dong, F. Zhang, Y.L. Kang, Blistering in semi-solid die casting of aluminum alloys and its avoidance. Acta Mater. 124, 446–455 (2017)

E.J. Vinarcik, High Integrity Die Casting Processes (Wiley, New York, 2002)

D.H. Kirkwood, Semisolid metal processing. Int. Mater. Rev. 39, 173–189 (1994)

Z. Fan, X. Fang, S. Ji, Microstructure and mechanical properties of rheo-diecast (RDC) aluminum alloys. Mater. Sci. Eng. A 412, 298–306 (2005)

L.Q. Yang, Y.L. Kang, F. Zhang, J. Xu, Microstructure and mechanical properties of rheo-diecasting AZ91D Mg alloy. Trans. Nonferrous Met. Soc. China 20, S862–S867 (2010)

P.K. Seo, S.M. Lee, C.G. Kang, A new process proposal for continuous fabrication of rheological material by rotational barrel with stirring screw and its microstructural evaluation. J. Mater. Process. Technol. 209, 171–180 (2009)

B. Zhou, Y.L. Kang, J. Zhang, J.Z. Gao, F. Zhang, Forced convection rheomoulding process for semisolid slurry preparation and microstructure evolution of 7075 aluminum alloy, in Proceedings of the 12th International Conference on Semi-Solid Processing of Alloys and Composites (S2P 2012), Cape Town, South Africa, 8–11 October 2012

M.F. Qi, Y.L. Kang, Q.Q. Qiu, W.C. Tang, J.Y. Li, B.S. Li, Microstructures, mechanical properties, and corrosion behavior of novel high-thermal-conductivity hypoeutectic Al–Si alloys prepared by rheological high pressure die-casting and high pressure die-casting. J. Alloys Compd. 749, 487–502 (2018)

D. Doutre, G. Hay, P. Wales, J.P. Gabathuler, Seed: a new process for semi-solid forming. Can. Metall. Q. 2, 265–272 (2004)

K. Du, W.Y. Qu, Y.H. Jing, Q. Zhu, Application of the correlation between hardness and strength in conventional Al alloys into semi solid processed products, in Proceedings of the 15th International Conference on Semi-Solid Processing of Alloys and Composites (S2P 2018), Shenzhen, China, 22–24 October 2018

M.F. Qi, Y.L. Kang, Q.Q. Qiu, Industrialized application of Rheo-HPDC process for the production of large thin-walled aluminum alloy parts, in Proceedings of the 15th International Conference on Semi-Solid Processing of Alloys and Composites (S2P 2018), Shenzhen, China, 22–24 October 2018

K.D. Bouzakis, G. Maliaris, A. Tsouknidas, FEM supported semisolid high pressure die casting process optimization based on rheological properties by isothermal compression tests at thixo temperatures extracted. Comput. Mater. Sci. 59, 133–139 (2012)

G. Li, H.X. Lu, X.G. Hu, Q. Zhu, Numerical simulation of slurry making process of 7075 aluminum alloy under electromagnetic field in rheo-casting process, in Proceedings of the 15th International Conference on Semi-Solid Processing of Alloys and Composites (S2P 2018), Shenzhen, China, 22–24 October 2018

B. Zhou, Y.L. Kang, M.F. Qi, H.H. Zhang, G.M. Zhu, R-HPDC process with forced convection mixing device for automotive part of A380 aluminum alloy. Materials 7, 3084–3105 (2014)

H.I. Laukli, High pressure die casting of aluminium and magnesium alloys grain structure and segregation characteristics. Ph.D. Thesis, Norwegian University of Science and Technology, Norwegian, Norway, 2004

D. Brungs, Light weight design with light metal castings. Mater. Des. 18, 285–291 (1997)

X.P. Niu, B.H. Hu, I.P. Pinwill, H. Li, Vacuum assisted high pressure die casting of aluminum alloys. J. Mater. Process. Technol. 105, 119–127 (2000)

K. Kubota, M. Mabuchi, K. Higashi, Review processing and mechanical properties of fine-grained magnesium alloys. J. Mater. Sci. 34, 2255–2262 (1999)

B. Ruttert, C. Meid, L.M. Roncery, I. Lopez-Galilea, M. Bartsch, W. Theisen, Effect of porosity and eutectics on the high-temperature low-cycle fatigue performance of a nickel-base single-crystal superalloy. Scripta Mater. 155, 139–143 (2018)

G.O. Verran, R.P.K. Mendes, L.V.O. Dalla Valentina, DOE applied to optimization of aluminum alloy die castings. J. Mater. Process. Technol. 200, 120–125 (2008)

Z. Fan, X. Fang, S. Ji, Microstructure and mechanical properties of rheo-diecast (RDC) aluminum alloys. Mater. Sci. Eng. A 412, 298–306 (2005)

J.W. Zhao, S.S. Wu, Microstructure and mechanical properties of rheo-diecasted A390 alloy. Trans. Nonferrous Met. Soc. China 20, S754–S757 (2010)

E. Mahallawi, H. Abdelkader, L. Shehata, A. Amer, J. Mayer, A. Schwedt, Influence of nanodispersions on properties and microstructure features of cast and T6 heat-treated Al Si hypoeutectic alloys. Solid State Phenom. 192–193, 76–82 (2013)

H. Möller, G. Govender, The heat treatment of rheo-high pressure die cast Al–Cu–Mg–Ag alloy 2139. Solid State Phenom. 192–193, 173–178 (2013)

W.X. Song, Metallography, 2nd edn. (Metallurgical Industry Press, Beijing, 1989), pp. 84–89

Acknowledgements

The authors gratefully acknowledge the financial supports by Shanghai Sailing Program (17YF1407100) and the Shanghai Pujiang Progran (17PJ1408600). The authors would like to appreciate Beijing General Research Institute for Nonferrous Metals for providing software support of Flow-3D.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Zhou, B., Lu, S., Xu, K. et al. Microstructure and Simulation of Semisolid Aluminum Alloy Castings in the Process of Stirring Integrated Transfer-Heat (SIT) with Water Cooling. Inter Metalcast 14, 396–408 (2020). https://doi.org/10.1007/s40962-019-00357-6

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00357-6