Abstract

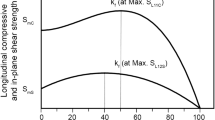

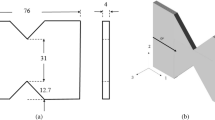

Engineering elastic constants and strength parameters shall be known to the designer in order to predict the structural response of composite materials. These properties shall be determined in various directions as per the designated standards. Testing of composite materials under the combined effect of in-plane shear and normal stress is of great importance. In this work, a new Arcan fixture has been designed, and then manufactured from aluminum alloy AA7075-T73. This test fixture can be used for uniaxial as well as biaxial testing of fiber reinforced polymers (FRPs) laminates in pure shear, and combined normal/shear stress states. Nevertheless, the fixture can be used for other materials where combined in-plane testing is required including metals and polymers. The special butterfly shape Arcan specimen was optimized based on the parametric study in ABAQUS environment by a Python scripting. The objective of the parametric study was to get a uniform shear stress field in the notch section of the specimen which is the cross-sectional area between the two opposite V-notch roots. The domain of the uniform shear stress-strain distribution in the notch section must be greater enough than the size of the strain gauge rosettes where these can be effectively installed for strain acquisition. The experimental set-ups for the realization of pure shear stress, normal stress, and combined normal/shear stress scenarios are schematically elaborated. The pure shear stress-strain response based on the Arcan test was compared with the tensile testing of ±450 symmetric laminate.

Similar content being viewed by others

References

Liu H, Falzon BG, Tan W (2018) Experimental and numerical studies on the impact response of damage-tolerant hybrid unidirectional/woven carbon-fibre reinforced composite laminates. Compos Part B 136:101–118

Olsson R (2011) A survey of test methods for multiaxial and out-of-plane strength of composite laminates. Compos Sci Technol 71(6):773–783

Almeida JHS, Angrizani CC, Botelho EC, Amico SC (2015) Effect of fiber orientation on the shear behavior of glass fiber/epoxy composites. Mater Des 65:789–795

Khashaba UA (2004) In-plane shear properties of cross-ply composite laminates with different off-axis angles. Compos Struct 65(2):167–177

Puck AS, H. (2002) Failure analysis of FRP laminates by means of physically based phenomenological models. Compos Sci Technol 62:1633–1663

Petersen E, Cuntze RG, Hühne C (2016) Experimental determination of material parameters in Cuntze's failure-mode-concept-based UD strength failure conditions. Compos Sci Technol 134:12–25

Cuntze RG (2006) Efficient 3D and 2D failure conditions for UD laminae and their application within the verification of the laminate design. Compos Sci Technol 66(7–8):1081–1096

Ud Din I, Panier S, Hao P, Franz G, Bijwe J, Hui L (2019) Finite element modeling of indentation and adhesive wear in sliding of carbon fiber reinforced thermoplastic polymer against metallic counterpart. Tribol Int 135:200–212

Arcan M, Hashin Z, Voloshin A (1977) A method to produce uniform plane-stress states with applications to Fiber-reinforced materials. Exp Mech:141–146

Smits LV, Swanson SR (1997) Design of a Cylindrical Specimen for biaxial testing of composite materials. J Reinf Plast Compos 16(6):550–564

El-Hajjar RH-A (2004) Rami. In-plane shear testing of thick-section pultruded FRP composites using a modified Arcan fixture. Compos Part B 35(5):421–428

Arcan M, Hashin Z, Voloshin A (1979) A method to produce uniform plane-stress states with applications to fiber-reinforced materials. Exp Mech 18:141–146

Hung SL, KM. (1997) An evaluation of the Arcan specimen for determining the shear moduli of Fiber-reinforced composites. Eng Mech 37:460–468

De Sousa Junior RR, Gouveia JR, Ito NM, dos Santos DJ (2017) Failure prediction of hybrid composite using Arcan's device and Drucker-Prager model. Polym Test 58:256–261

Tan JLY, Deshpande VS, Fleck NA (2015) Failure mechanisms of a notched CFRP laminate under multi-axial loading. Compos A: Appl Sci Manuf 77:56–66

Tan JLY, Deshpande VS, Fleck NA (2017) The effect of laminate lay-up on the multi-axial notched strength of CFRP panels: simulation versus experiment. Eur J Mech - A/Solids 66:309–321

Tan JL, Deshpande VS, Fleck NA (2016) Prediction of failure in notched carbon-fibre-reinforced-polymer laminates under multi-axial loading. Philosophical Transactions of the Royal Society A: Mathematical, Physical and Engineering Sciences 374(2071):20150273

Alfonso L, Uguen A, Badulescu C, Cognard JY, Bonnemains T, Lolive E et al (2015) Determination of the 3D failure envelope of a composite based on a modified Arcan test device. Compos Struct 131:585–593

Cognard JY, Sohier L, Davies P (2011) A modified Arcan test to analyze the behavior of composites and their assemblies under out-of-plane loadings. Compos A: Appl Sci Manuf 42(1):111–121

Gning PB, Delsart D, Mortier JM, Coutellier D (2010) Through-thickness strength measurements using Arcan’s method. Compos Part B 41(4):308–316

Li Y, Zhang K, Zhang B (2003) Shear Fatigue Test and Life Prediction of Composite Laminates Trans Tech Publications, Switzerland

Sawadogo H, Panier S, Hariri S (2013) Experimental and Numerical Study of the Fatigue of GFRP Composites under Complex Loadings. In: Proceedings of ICMFF10. Japan, Conference, Conference

Smits A, Van Hemelrijck D, Philippidis TP, Cardon A (2006) Design of a cruciform specimen for biaxial testing of fibre reinforced composite laminates. Compos Sci Technol 66(7–8):964–975

Yen S, Craddock J, Teh K (1998) Evaluation of a modified Arcan fixture for the in-plane shear test of materials. Exp Tech 12:22–27

Gan KW, Laux T, Taher ST, Dulieu-Barton JM, Thomsen OT (2018) A novel fixture for determining the tension/compression-shear failure envelope of multidirectional composite laminates. Compos Struct 184:662–673

Hung SL, KM. (1999) Finite element analysis of the Arcan specimen for Fiber reinforced composites under pure shear and biaxial loading. J Compos Mater 33:1288–1317

Laux T, Gan KW, Dulieu-Barton JM, Thomsen OT (2019) A simple nonlinear constitutive model based on non-associative plasticity for UD composites: development and calibration using a modified Arcan fixture. Int J Solids Struct 162:135–147

Ud Din I, Hao P, Franz G, Panier S (2018) Elastoplastic CDM model based on Puck’s theory for the prediction of mechanical behavior of Fiber reinforced polymer (FRP) composites. Compos Struct 201:291–302

Acknowledgments

The corresponding author (Israr Ud Din) and the second author (Pei Hao) are extremely grateful to their governments, Pakistan (Higher Education Commission, HEC, in collaboration with Campus France), and China (China Scholarship Council, CSC), respectively, for the provision of financial support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of Interest

The authors declare that they have no conflict of interest.

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ud Din, I., Hao, P., Panier, S. et al. Design of a New Arcan Fixture for In-plane Pure Shear and Combined Normal/Shear Stress Characterization of Fiber Reinforced Polymer Composites. Exp Tech 44, 231–240 (2020). https://doi.org/10.1007/s40799-019-00353-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40799-019-00353-9