Abstract

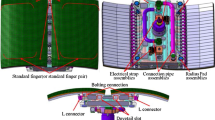

Limited CFETR-scale experience of engineering preparation techniques of tritium permeation barrier (TPB) exists up to date. Aimed at processing some real components that are usually tubular components sealed in one end, in the tritium cycling systems of China Fusion Engineering Test Reactor (CFETR), an Al2O3/FeAl coatings as TPB was prepared on tubular components of 321 type stainless steel components with a length of 400 mm and an external diameter of 150 mm, by Al-electroplating followed by heat treating and selective oxidation. The ability to construct TPB coated components on quasi-CFETR scale was demonstrated, with fabricating a TPB of Al2O3/FeAl coating with a double-layered structure, consisted of an outer γ-Al2O3 layer with a thickness of 0.3 µm and an inner (Fe,Cr,Ni)Al/(Fe,Cr,Ni)3Al layer of 40 µm in thickness. The tritium permeation reduction factors of the Al2O3/FeAl TPB on component were 229 and 96 at 500 and 600 °C respectively. Finally, signatures and gaps of TPB mass process on CFETR-scale were discussed.

Similar content being viewed by others

References

T. Tanabe, Tritium fuel cycle in ITER and DEMO: issues in handling large amount of fuel. J. Nucl. Mater. 438, S19–S26 (2013)

R.A. Causey, R.A. Karnesky, C. San Marchi, Tritium barriers and tritium diffusion in fusion reactors. Compr. Nucl. Mater. 4, 11–49 (2012)

I.R. Cristescu, I. Cristescu, L. Doerr, M. Glugla, D. Murdoch, Tritium inventories and tritium safety design principles for the fuel cycle of ITER. Nucl. Fusion 47, S458–S463 (2007)

A. Perujo, K.S. Forcey, Tritium permeation barriers for fusion technology. Fusion Eng. Des. 28, 252–257 (1995)

J. Konys, Review of tritium permeation barrier development for fusion application in the EU, in Proceedings of ITER TBM Project Meeting, 2004, UCLA

J. Konys, Development of advanced processes for Al-based anticorrosion and T-permeation barriers, in 9th International Symposium of Fusion Nuclear Technology, 2009, Dalian, China

J. Konys, W. Krauss, N. Holstein, Development of advanced processes for Al-based anticorrosion and T-permeation barriers. Fusion Eng. Des. 85, 2141–2145 (2010)

E.R. Kumar, C. Danani, I. Sandeep, C. Chakrapani, P.N. Ravi, V. Chaudhari, Preliminary design of Indian Test Blanket Module for ITER. Fusion Eng. Des. 83, 1169–1172 (2008)

D.L. Luo, J.F. Song, G.Q. Huang, C.A. Chen, Z.Y. Huang, X.J. Deng, Progress of China’s TBM Tritium Technology Progress of China’s TBM Tritium Technology Progress of China’s TBM Tritium Technology. Fusion Eng. Des. 87, 1261–1267 (2012)

C.P.C. Wong, J.F. Salavy, Y. Kim, I. Kirillov, E.R. Kumar, N.B. Morley et al., Overview of liquid metal TBM concepts and programs. Fusion Eng. Des. 83, 850–857 (2008)

K.S. Forcey, D.K. Ross, The formation of hydrogen permeation barriers on steels by aluminizing. J. Nucl. Mater. 182, 36–51 (1991)

A. Aiello, A. Ciampichetti, G. Benamati, An overview on tritium permeation barrier development for WCLL blanket concept. J. Nucl. Mater. 329, 333, 1398–1402 (2004)

H.G. Yang, Q. Zhan, W.W. Zhao, X.M. Yuan, Y. Hu, Z.B. Han, Study of an iron-aluminide and alumina tritium barrier coating. J. Nucl. Mater. 417, 1237–1240 (2011)

C. Wei, G. Sang, J.F. Song, D.L. Luo, C.A. Chen, A deuterium permeation barrier by hot-dipping aluminizing on AISI321 steel. Int. J. Hydrogen Energy 48, 23125–23131 (2016)

G.K. Zhang, J. Li, C.A. Chen, S.P. Dou, G.P. Ling, Tritium permeation barrier-aluminized coating prepared by Al-plating and oxidation process. J. Nucl. Mater. 417, 1245–1248 (2011)

G.K. Zhang, C.A. Chen, D.L. Luo, X.L. Wang, An advance process of aluminum rich coating as tritium permeation barrier on 321 steel workpiece. Fusion Eng. Des. 87, 1370–1375 (2012)

F.L. Yang, X. Xiang, G.D. Lu, G.K. Zhang, T. Tang et al., Tritium permeation characterization of Al2O3/FeAl coating as tritium permeation barrier on 321 steel container. J. Nucl. Mater. 478, 144–148 (2016)

C.A. Chen, D.L. Luo, J.F. Song, Z.Y. Huang, Design description document for CFETR fuel cycle (China Academy of Engineering Physics, Beijing, 2015)

G.K. Zhang, J. Li, C.A. Chen, Z.Y. Huang, G.P. Ling, New preparing method and performance of FeAl/Al2O3 tritium permeation barrier. Rare Metal Mater. Eng. 39, 1290–1294 (2010). (in Chinese)

G.K. Zhang, J. Li, C.A. Chen, Y. Li, G.P. Ling, Low-temperature Formation of aluminide coatings on HR-2 stainless steel. Acta Metall. Sin. 28, 983–987 (2009). (in Chinese)

N. Yeremenko, Y.V. Natanzon, V.I. Dybkov, The effect of dissolution on the growth of the Fe2Al5 interlayer in the solid iron–liquid aluminium system. J. Mater. Sci. 16, 1748–1756 (1981)

S.-E. Wulf, W. Krauss, J. Konys, Needs and gaps in the development of aluminum-based corrosion and T-permeation barriers for DEMO blankets. Fusion Eng. Des. 98&99, 2098–2102 (2015)

Z.G. Zhang, F. Gesmundo, P.Y. Hou, Criteria for the formation of protective Al2O3 scales on Fe–Al and Fe–Cr–Al alloys. Corros. Sci. 48, 741–765 (2006)

H.L. de Maubeuge, Influence of geometric variables on the current distribution uniformity at the edge of parallel plate electrodes. Electrochim. Acta 56, 10603–10611 (2011)

M. Zamanzade, A. Barnoush, C. Motz, A review on the properties of iron aluminide itermetallics. Crystals 6, 10–29 (2016)

R. Brajpuriya, T. Shripathi, Investigation of Fe/Al interfaces as a function of annealing temperature using XPS. Appl. Surf. Sci. 225, 6149–6154 (2009)

Acknowledgements

This work is supported by National Natural Science Foundation (No. 21471137) and National Magnetic Confinement Fusion Science Program (No. 2017YFE0300304) of China. We appreciate Mr. Jing Wenyong and Mr. Yang Pengfei for tritium permeation experiments.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Zhang, G., Yang, F., Lu, G. et al. Fabrication of Al2O3/FeAl Coating as Tritium Permeation Barrier on Tritium Operating Component on Quasi-CFETR Scale. J Fusion Energ 37, 317–324 (2018). https://doi.org/10.1007/s10894-018-0201-2

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10894-018-0201-2