Abstract

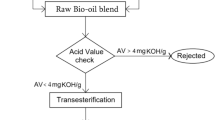

Biodiesel is an alternative sustainable energy source and can be utilized in the compression ignition engine without any changes in the engine design. This research work focuses on the preparation of Calophyllum inophyllum methyl ester through two steps of transesterification process and its implementation in common rail direct injection diesel engines under various fuel injection strategies. At the initial stage of the current research work, two biodiesel blends of 10 vol% and 20 vol% with remaining quantity as diesel have been used as fuel in a diesel engine at a fuel injection pressure of 600 bar at 5%, 10% and 15% pilot injection variations. In the second stage, the study has been extended for the same strategies of injecting the fuel at the rates of 10% and 20% exhaust gas recirculation. All the experimental results are compared with diesel fuel at an injection pressure of 600 bar with 10% pilot injection. The experimental results revealed that an increase in the blend ratio of biodiesel enhances the combustion, performance characteristics and proliferation of pilot injection from 5 to 15% facilitates spontaneous and complete combustion. It is observed that 15% pilot injection quantity of 20 vol% Calophyllum inophyllum methyl ester blend has shown the best performance among the test samples with other injection strategies. The results also showed that the implementation of exhaust gas recirculation at 10% and 20% rates during diesel engine operation is evident in lower performance characteristics with a significant impact on oxides of nitrogen and carbon dioxide emissions.

Graphic abstract

Similar content being viewed by others

Abbreviations

- ATDC:

-

After top dead center

- CIB10:

-

CIME biodiesel quantity of 10% vol

- CIB10@Pilot-10%:

-

CIB10 (pilot injection quantity of 10% vol)

- CIB10@Pilot-10%@EGR10%:

-

CIB10 (pilot injection quantity of 10% vol) with 10% EGR

- CIB10@Pilot-10%@EGR20%:

-

CIB10 (pilot injection quantity of 10% vol) with 20% EGR

- CIB10@Pilot-15%:

-

CIB10 (pilot injection quantity of 15% vol)

- CIB10@Pilot-5%:

-

CIB10 (pilot injection quantity of 5% vol)

- CIB100:

-

CIME biodiesel quantity of 100% vol

- CIB20:

-

CIME biodiesel quantity of 20% vol

- CIB20@Pilot-10%:

-

CIB20 (pilot injection quantity of 10% vol)

- CIB20@Pilot-10%@EGR10%:

-

CIB20 (pilot injection quantity of 10% vol) with 10% EGR

- CIB20@Pilot-10%@EGR20%:

-

CIB20 (pilot injection quantity of 20% vol) with 20% EGR

- CIB20@Pilot-15%:

-

CIB20 (pilot injection quantity of 15% vol)

- CIB20@Pilot-5%:

-

CIB20 (pilot injection quantity of 5% vol)

- BMEP:

-

Brake mean effective pressure

- BSEC:

-

Brake specific energy consumption

- BSFC:

-

Brake specific fuel consumption

- BTDC:

-

Before top dead center

- BTE:

-

Brake thermal efficiency

- CHRR:

-

Cumulative heat release rate

- CIME:

-

Calophyllum inophyllum methyl ester

- DOC:

-

Diesel oxidation catalyst

- HRR:

-

Heat release rate

- ID:

-

Ignition delay

- JBD:

-

Jatropha oil-derived biodiesel

- ME:

-

Mechanical efficiency

- MFB:

-

Mass fraction burnt

- rpm:

-

Revolutions per minute

- VCR:

-

Variable compression ratio

- VOC:

-

Volatile organic compound

References

Agarwal AK, Dhar A, Srivastava DK, Maurya RK, Singh AP (2013) Effect of fuel injection pressure on diesel particulate size and number distribution in a CRDI single cylinder research engine. Fuel 107:84–89

Ashok B, Nanthagopal K, Raj RT, Bhasker JP, Vignesh DS (2017) Influence of injection timing and exhaust gas recirculation of a Calophyllum inophyllum methyl ester fuelled CI engine. Fuel Process Technol 167:18–30

Atabani AE, Silitonga AS, Ong HC, Mahlia TM, Masjuki HH, Badruddin IA, Fayaz H (2013) Non-edible vegetable oils: a critical evaluation of oil extraction, fatty acid compositions, biodiesel production, characteristics, engine performance and emissions production. Renew Sustain Energy Rev 18:211–245

Ayodele OO, Dawodu FA (2014) Production of biodiesel from Calophyllum inophyllum oil using a cellulose-derived catalyst. Biomass Bioenerg 70:239–248

Buyukkaya E (2010) Effects of biodiesel on a DI diesel engine performance, emission and combustion characteristics. Fuel 89(10):3099–3105

Can Ö, Öztürk E, Solmaz H, Aksoy F, Çinar C, Yücesu HS (2016) Combined effects of soybean biodiesel fuel addition and EGR application on the combustion and exhaust emissions in a diesel engine. Appl Therm Eng 95:115–124

Chuah LF, Aziz AR, Yusup S, Bokhari A, Klemeš JJ, Abdullah MZ (2015) Performance and emission of diesel engine fuelled by waste cooking oil methyl ester derived from palm olein using hydrodynamic cavitation. Clean Technol Environ Policy 17(8):2229–2241

Chuah LF, Yusup S, Aziz AR, Bokhari A, Abdullah MZ (2016) Cleaner production of methyl ester using waste cooking oil derived from palm olein using a hydrodynamic cavitation reactor. J Clean Prod 112:4505–4514

Chuah LF, Klemeš JJ, Yusup S, Bokhari A, Akbar MM (2017a) Influence of fatty acids in waste cooking oil for cleaner biodiesel. Clean Technol Environ Policy 19(3):859–868

Chuah LF, Klemeš JJ, Yusup S, Bokhari A, Akbar MM (2017b) A review of cleaner intensification technologies in biodiesel production. J Clean Prod 146:181–193

Damodharan D, Sathiyagnanam AP, Rana D, Kumar BR, Saravanan S (2018) Combined influence of injection timing and EGR on combustion, performance and emissions of DI diesel engine fueled with neat waste plastic oil. Energy Convers Manag 161:294–305

Demirbaş A (2003) Biodiesel fuels from vegetable oils via catalytic and non-catalytic supercritical alcohol transesterifications and other methods: a survey. Energy Convers Manag 44(13):2093–2109

Duda K, Wierzbicki S, Śmieja M, Mikulski M (2018) Comparison of performance and emissions of a CRDI diesel engine fuelled with biodiesel of different origin. Fuel 212:202–222

Fattah IR, Masjuki HH, Kalam MA, Wakil MA, Ashraful AM, Shahir SA (2014) Experimental investigation of performance and regulated emissions of a diesel engine with Calophyllum inophyllum biodiesel blends accompanied by oxidation inhibitors. Energy Convers Manag 83:232–240

Gopal KN, Pal A, Sharma S, Samanchi C, Sathyanarayanan K, Elango T (2014) Investigation of emissions and combustion characteristics of a CI engine fueled with waste cooking oil methyl ester and diesel blends. Alex Eng J 53(2):281–287

Han D, Duan Y, Wang C, Lin H, Huang Z (2015) Experimental study on the two stage injection of diesel and gasoline blends on a common rail injection system. Fuel 159:470–475

How HG, Masjuki HH, Kalam MA, Teoh YH (2018) Influence of injection timing and split injection strategies on performance, emissions, and combustion characteristics of diesel engine fueled with biodiesel blended fuels. Fuel 213:106–114

Keskin A, Gürü M, Altiparmak D, Aydin K (2008) Using of cotton oil soapstock biodiesel–diesel fuel blends as an alternative diesel fuel. Renew Energy 33(4):553–557

Kumar BR, Saravanan S, Rana D, Nagendran A (2016) Combined effect of injection timing and exhaust gas recirculation (EGR) on performance and emissions of a DI diesel engine fuelled with next-generation advanced biofuel–diesel blends using response surface methodology. Energy Convers Manag 123:470–486

Li H, Song C, Lv G, Pang H, Qiao Y (2017) Assessment of the impact of post-injection on exhaust pollutants emitted from a diesel engine fueled with biodiesel. Renew Energy 114:924–933

Liu J, Wang H, Zheng Z, Mao B, Li L, Yao M (2017) Effects of pilot injection strategy on combustion and emission characteristics in gasoline compression ignition. Energy Procedia 142:1267–1273

Lund H (2007) Renewable energy strategies for sustainable development. Energy 32(6):912–919

Mahla SK, Dhir A, Gill KJ, Cho HM, Lim HC, Chauhan BS (2018) Influence of EGR on the simultaneous reduction of NOx-smoke emissions trade-off under CNG-biodiesel dual fuel engine. Energy 152:303–312

Mikulski M, Duda K, Wierzbicki S (2016) Performance and emissions of a CRDI diesel engine fuelled with swine lard methyl esters–diesel mixture. Fuel 164:206–219

Mosarof MH, Kalam MA, Masjuki HH, Alabdulkarem A, Ashraful AM, Arslan A, Rashedul HK, Monirul IM (2016) Optimization of performance, emission, friction and wear characteristics of palm and Calophyllum inophyllum biodiesel blends. Energy Convers Manag 118:119–134

Muralidharan K, Vasudevan D, Sheeba KN (2011) Performance, emission and combustion characteristics of biodiesel fuelled variable compression ratio engine. Energy 36(8):5385–5393

Muthukumaran N, Saravanan CG, Yadav SP, Vallinayagam R, Vedharaj S, Roberts WL (2015) Synthesis of cracked Calophyllum inophyllum oil using fly ash catalyst for diesel engine application. Fuel 155:68–76

Nanthagopal K, Ashok B, Raj RT (2016) Influence of fuel injection pressures on Calophyllum inophyllum methyl ester fuelled direct injection diesel engine. Energy Convers Manag 116:165–173

Ong HC, Mahlia TM, Masjuki HH, Norhasyima RS (2011) Comparison of palm oil, Jatropha curcas and Calophyllum inophyllum for biodiesel: a review. Renew Sustain Energy Rev 15(8):3501–3515

Ong HC, Masjuki HH, Mahlia TM, Silitonga AS, Chong WT, Leong KY (2014) Optimization of biodiesel production and engine performance from high free fatty acid Calophyllum inophyllum oil in CI diesel engine. Energy Convers Manag 81:30–40

Ozsezen AN, Canakci M, Sayin C (2008) Effects of biodiesel from used frying palm oil on the performance, injection, and combustion characteristics of an indirect injection diesel engine. Energy Fuels 22:1297–1305

Palash SM, Kalam MA, Masjuki HH, Arbab MI, Masum BM, Sanjid A (2014) Impacts of NOx reducing antioxidant additive on performance and emissions of a multi-cylinder diesel engine fueled with Jatropha biodiesel blends. Energy Convers Manag 77:577–585

Qi D, Leick M, Liu Y, Chia-fon FL (2011) Effect of EGR and injection timing on combustion and emission characteristics of split injection strategy DI-diesel engine fueled with biodiesel. Fuel 90(5):1884–1891

Sahoo PK, Das LM (2009) Process optimization for biodiesel production from Jatropha, Karanja and Polanga oils. Fuel 88(9):1588–1594

Sahoo PK, Das LM, Babu MKG, Naik SN (2009) Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 86(3):448–454

Sanjid A, Masjuki HH, Kalam MA, Rahman SA, Abedin MJ, Palash SM (2014) Production of palm and jatropha based biodiesel and investigation of palm-jatropha combined blend properties, performance, exhaust emission and noise in an unmodified diesel engine. J Clean Prod 65:295–303

Sathyaselvabala V, Ponnusamy S, Periyaraman PM, Selvaraj DK, Thangaraj V, Subramanian S (2012) Two step biodiesel production from Calophyllum inophyllum oil: studies on thermodynamic and kinetic modelling of modified β-zeolite catalysed pre-treatment. Can J Chem Eng 90(5):1178–1185

Shiga S, Ehara H, Karasawa T, Kurabayashi T (1988) Effect of exhaust gas recirculation on diesel knock intensity and its mechanism. Combust Flame 72(3):225–234

Sonar D, Soni SL, Sharma D, Srivastava A, Goyal R (2015) Performance and emission characteristics of a diesel engine with varying injection pressure and fuelled with raw mahua oil (preheated and blends) and mahua oil methyl ester. Clean Technol Environ Policy 17(6):1499–1511

Van Gerpen J (2005) Biodiesel processing and production. Fuel Process Technol 86(10):1097–1107

Venkanna BK, Reddy CV (2009) Biodiesel production and optimization from Calophyllum inophyllum linn oil (honne oil)—a three stage method. Biores Technol 100(21):5122–5125

Venkateswarlu K, Murthy BS, Subbarao VV (2013) The effect of exhaust gas recirculation and di-tertiary butyl peroxide on diesel–biodiesel blends for performance and emission studies. Int J Adv Sci Technol 54:49–60

Xu M, Cheng W, Li Z, Zhang H, An T, Meng Z (2016) Pre-injection strategy for pilot diesel Compression ignition natural gas engine. Appl Energy 179:1185–1193

Yun H, Choi K, Lee CS (2016) Effects of biobutanol and biobutanol–diesel blends on combustion and emission characteristics in a passenger car diesel engine with pilot injection strategies. Energy Convers Manag 111:79–88

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There are no conflicts to declare in this manuscript for publication.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Electronic supplementary material

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Nanthagopal, K., Ashok, B., Susanth Kishna, R. et al. Experimental investigation on engine parameters variation in common rail direct injection engine fueled with biodiesel. Clean Techn Environ Policy 22, 459–479 (2020). https://doi.org/10.1007/s10098-019-01796-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10098-019-01796-9