Abstract

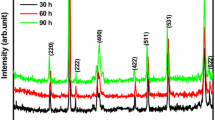

Cerium (Ce3+)-substituted cobalt–nickel (Co–Ni) ferrite nanostructures of spinel cubic phase with space group Fd\(\bar{3}\)m had been successfully engineered by solution combustion route. The effect of Ce3+ substitution on the structural, morphological, dielectric, and impedance spectroscopic investigations are probed by using X-ray diffraction (XRD), scanning electron microscope (SEM), and impedance analysis, respectively. Rietveld refinement of XRD data reveal that samples exhibit well-crystalline nature with single phase. The microstructural realm with various Ce3+ doping levels has been identified from SEM micrographs. The replacement of Fe3+ by Ce3+ cations has been confirmed by using energy-dispersive analysis of the ferrite samples. The dielectric constant (ε′), dielectric loss (tanδ), ac conductivity (σac), and impedance (Z′ and Z″) at room temperature is investigated as a function of frequency, respectively. The variation of dielectric properties ε′, tanδ, σac with frequency are explained by Maxwell–Wagner type of interfacial polarization and the hopping of charge between Fe2+ and Fe3+ as well as the dopant ions at B-sites. The decrease in dielectric constant and dielectric loss tangent with frequency follows the phenomenon of Debye’s relaxation. The enhancement in AC conductivity with frequency is proportional to Ce3+ concentration which follows Jonscher law. The complex impedance plots (Z′ vs. Z″) allows to determine the contribution for conductivity either from grain or grain boundary. Complex electric modulus plot (M′ vs. M″) provides the validation to the result drawn from the complex impedance plots. The results indicate the existence of non-Debye type of relaxation in these ferrites. Impedance spectroscopy allows the ferrite materials to estimate electrical properties which arise due to hopping and relaxation phenomena.

Similar content being viewed by others

References

H Z Duan, F L Zhou, X Cheng, G H Chen and Q L Li J. Magn. Magn. Mater.424 467 (2017)

V Jagadeesha Angadi, B Rudraswamy, K Sadhana, S R Murthy and K Praveena J. Alloy. Compd. 656 5 (2016)

K Ali, J Iqbal, T Jan, I Ahmad, D Wan and I Ahmad Mater. Chem. Phys.195 283 (2017)

A Ditta, M A Khana, M Junaid, R M A Khalil and M F Warsi Phys. B507 27 (2017)

V Jagadeesha Angadi, A V Anupama, R Kumar, S Matteppanavar, B Rudraswamy, B Sahoo J. Alloy Compd.682 263 (2016)

M Ajmal, M U Islam, G A Ashraf, M A Nazir and M I Ghouri, Phys. B.526 149 (2017)

K M Srinivasamurthy, V Jagadeesha Angadi, S P Kubrin, S Matteppanavar, P M Kumar, B Rudraswamy Ceram. Int.44 18878 (2018)

A Saini, P Kumar, B Ravelo, S Lallechere, A Thakur and P Thakur Int. J. Eng. Sci. Technol.19 911 (2016)

K Subbiah, L Han-Seung, L Y Su, J S Kumar, K Seung-Jun and N Rethinam Sens. Actuators B251 509 (2017)

B G Toksha, S E Shirsath, M L Mane and K M Jadhav Ceram. Int.43 14347 (2017)

T K Bromho, K Ibrahim, H Kabir, M M Rahman, K Hasan, T Ferdous, H Taha, M Altarawneh and Z-T Jiang Mater. Res. Bull.97 444 (2018)

M A Dar, K Majid, M H Najar, R K Kotnala, J Shah, S K Dhawan and M Farukh Phys. Chem. Chem. Phys.19 10629 (2017)

R Nivetha, C Santhosh, P Kollu, S K Jeong, A Bhatnagar and A N Grace J. Magn. Magn. Mater.448 165 (2018)

A A El Ata, M El Nimr, S Attia, D El Kony and A Al-Hammadi J. Magn. Magn. Mater.297 33 (2006)

M Y Lodhi, K Mahmood, A Mahmood, H Malik, M F Warsi, I Shakir, M Asghar and M A Khan Curr. Appl. Phys.14 716 (2014)

S Haralkar, R Kadam, S More, S E Shirsath, M Mane, S Patil and D Mane Phys. B: Condens. Matter.407 4338 (2012)

A B Gadkari, T J Shinde and P N Vasambekar Mater. Res. Bull.48 76 (2013)

V Jagadeesha Angadi, B Rudraswamy, K Sadhana, K Praveena J. Magn. Magn. Mater.409 111 (2016)

Z H Khan, M M Rahman, S S Sikder, M A Hakim and D K Saha J. Alloy. Compd.548 208 (2013)

S Pervin, M M Rahman, F Ahmed and M A Hakim Indian J. Phys86 12 (2012)

K M Srinivasamurthy, V Jagadeesha Angadi, S P Kubrin, S Matteppanavar, D A Sarychev, P M Kumar, H W Azale, B Rudraswamy Ceram. Int.44 9194 (2018)

M M Rahman, P K Halder, F Ahmed, T Hossain and M Rahaman J. Sci. Res.4 p 297 (2012)

V Jagadeesha Angadi, L Choudhury, K Sadhana, H-L Liu, R Sandhya, S Matteppanavar, B Rudraswamy, V Pattar, R V Anavekar and K Praveena J. Magn. Magn. Mater.424 1 (2017)

V Jagadeesha Angadi et al. Ceram. Int.43 523 (2016)

M F Al-hilli, S Li and K S Kassim J. Magn. Magn. Mater.324 873 (2012)

M M Rahman et al. J. Bangladesh Acad. Sci.36 199 (2012)

M M Mallapur,et al., J. Alloy. Compd.479 p 797 (2009)

C G Koops Phys. Rev.83 121 (1951)

J C Maxwell A Treatise on Electricity and Magnetism (New York: Oxford University Press) (1954)

R C Kambale, P A Shaikh, C H Bhosale, K Y Rajpure and Y D Kolekar Smart Mater. Struct.18 085014 (2009)

D Varshney and K Verma Mater. Chem. Phys.140 412 (2013)

S B Patil, R P Patil, J S Ghodake and B K Chougule J. Magn. Magn. Mater.350 179 (2014)

U B Sontu, V Yelasani and V R R Musugu J. Magn. Magn. Mater.374 376 (2015)

K S Hemalatha, G Sriprakash, M V N A Prasad, R Damle and K Rukmani J. Appl. Phys.118 154103 (2015)

R G Kharabe, R S Devan, C M Kanamadi and B K Chougule Smart Mater. Struct.15 N36 (2006)

J Parashar, V K Saxena, J Sharma, D Bhatnagar and K B Sharma Macromol. Symp.357 43 (2015)

N Kumari, V Kumar and S K Singh RSC Adv.5 37925 (2015)

R S Devan, Y-R Ma and B K Chougule Mater. Chem. Phys.115 263 (2009)

M H Alimuddin, S Kumar, S E Shirsath, R K Kotnala, J Shah and R Kumar Mater. Chem. Phys.139 364 (2013)

K K Bharathi, J A Chelvane and G Markandeyulu J. Magn. Magn. Mater.321 3677 (2009)

K M Batoo and M S Ansari Nanoscale Res. Lett.7 112 (2012)

R Pandit, K K Sharma, P Kaur, R K Kotnala, J Shah and R Kumar J. Phys. Chem. Solids.75 558 (2014)

O M Hemeda, N Y Mostafa, O H AbdElkader, D M Hemeda, A Tawfik and M Mostafa J. Magn. Magn. Mater.394 96 (2015)

K M Batoo, S Kumar, C G Lee and M H Alimuddin, J. Alloy. Compd.480 596 (2009)

A A Kadam, S S Shinde, S P Yadav, P S Patil and K Y Rajpure, J. Magn. Magn. Mater.329 59 (2013)

A Sinha and A Dutta RSC Adv.5 100330 (2015)

H S Aziz, S Rasheed, R A Khan, A Rahim, J Nisar, S M Shah, F Iqbal and A R Khan RSC Adv.6 6589 (2016)

E Pervaiz and I H Gul, J. Phys. Conf. Ser.439 012015 (2013)

R S Yadav, I Kuřitka, J Vilcakova, J Havlica, L Kalina, P Urbánek, M Machovsky, D Skoda, M Masar and M Holek Ultrason. Sonochem.40 773 (2018)

A K Pradhan, P R Mandal, K Bera, S Saha and T K Nath Phys. B.525 1 (2017)

Acknowledgements

This work is partially supported by the Ministry of Education and Science of the Russian Federation (Projects 3.5346.2017/8.9). This study is partially supported by the Ministry of Education and Science of the Russian Federation (Projects 3.6371.2017/8.9, 3.6439.2017/8.9). The dielectric spectroscopy measurements were performed using the equipment of the Shared Research Facility Centre of Research Institute of Physics, Southern Federal University.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Srinivasamurthy, K.M., Manjunatha, K., Sitalo, E.I. et al. Effect of Ce3+ substitution on the structural, morphological, dielectric, and impedance spectroscopic studies of Co–Ni ferrites for automotive applications. Indian J Phys 94, 593–604 (2020). https://doi.org/10.1007/s12648-019-01495-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12648-019-01495-7