Abstract

The present work emphasizes the effect of the use of Sn, with different concentrations, over the structural properties and sensing applications of LaCrO3. In this work, LaCrO3 nanostructures were modified with different concentration of Sn (0.2 M %, 0.4 M %, 0.6 M % and 0.8 M %).Different modified Sn-doped LaCrO3 was synthesized by sol–gel method and followed by preparation of thick films via a conventional screen printing approach. The characterizations done by means of X-ray diffraction (XRD), energy-dispersive X-ray (EDX), scanning electron microscopy (SEM) and transmission electron microscopy (TEM) revealed the confirmation of a Sn-doped LaCrO3 crystal structure and its morphology, respectively. These oxides were formulated to identify various air pollutants such as CO2, ethanol, H2S, NH3, NO2, and acetone. The Sn-doped LaCrO3 with 0.4 M % Sn displayed higher gas response to ethanol vapor at the range of 150–250 °C. The sensors additionally demonstrated proper recovery and acceptable stability.

Graphic abstract

The graphical abstract demonstrates the in situ synthesis of Sn-doped LaCrO3 by sol–gel method. Similarly, it shows its characterization and finally, the thick films of doped Sn demonstrate best selectivity for ethanol.

Similar content being viewed by others

Introduction

The continuous increase in the release of the toxic pollutants from industries and vehicles in the environment has posed a threat to the human and other living beings surroundings globally. In these circumstances, measures to tackle this global problem are necessary. At this juncture, the significance of nanomaterial is crucial and there use is increasing day by day. The gas sensors designed using such nanomaterial play a vital role in human and environment safety.

The metal oxide gas sensors are utilized to recognize various poisonous gases which can pose risk to human health and surroundings [1]. Perovskite compounds, ABO3 (in which A = cation of alkali, alkaline earth, or lanthanide steel and B = cation of transition metal), have novel synthetic and physical properties such as oxidative, magnetic, conductive, refractive, luminescent and catalytic. With these significant and interesting attributes, these oxides have been widely used in electronic devices and plenty of other devices [2]. These oxides are also used in optoelectronic devices [3], hydrazine and ozone sensor [4, 5], tremendous magneto-resistance [6], magneto-electric [7], interconnect material [8], light-emitting material [9] and as a catalyst [10]. Perovskite structural material (ABO3) can be prepared by mixing the lanthanide oxide and the oxides of the transition element. In the perovskite structure, the cations can fit into both the A and B sites [11]. These perovskites were blended using various methods such as hydrothermal [12,13,14], co-precipitation [15,16,17], sol–gel [18, 19]. Among these methods, the sol–gel method has been viewed and appreciated by various researchers due to excellent quality of the resulted nanomaterials. Besides this, this strategy is relatively cost effective [20]. The first use of (Ln, M)BO3 (Ln—lanthanide element, M—alkaline earth metal, and B—transition metal) perovskite as a potential ethanol sensor was proposed by Obayashi et al. [21].

According to OSHA, ethanol is a volatile, flammable and colorless liquid with a wine-like scent. It burns with a smokeless blue fire that is not visible in ordinary light. It is an excellent psychoactive drug. It can result in irritation of eyes, skin and upper respiratory tract mucous membrane. The primary metabolic results of ethanol in the liver are acetaldehyde is toxic, mutagenic and carcinogenic. Exposure of ethanol may be very harmful to the human being as it causes nausea and omitting. These types of signs and symptoms directly damage the liver. Therefore, it is important to screen and understand the fixation of ethanol for human safety and at last in the surroundings. One of the significant factors which influence the sensing property of gas sensors is introducing the dopants, catalyzers. Dopants are introduced to the metal oxide during the synthesis to change the electrical properties of the synthesized material. Dopant normally isolates along the grain boundaries in polycrystalline material and restricts grain development in subsequent annealing. By adding dopant it creates some kind of defects such as ionic and electronic. The Fermi energy level affected by such form of deformities helps to increase the gas sensitivity of the semiconductor oxides. Many researchers have introduced dopants to enhance the sensitivity and selectivity of the oxides. Since many years, researchers have been continuously showing an inclination towards preparing value-effective SnO2 thin and thick films. In the field of gas sensing, the most commonly used metal oxide semiconductor is tin oxide. The reason behind it is the potential to recognize ignitable and polluted gases such as methane, LPG, CNG, CO, CO2, Cl2, H2S, and so on [22, 23].

In recent times, the majority of street accidents are resulting from drunken driving. Drunken drivers are in an unstable situation and so possibilities of an accident have been a major trouble; that is why the effective tracking of drunken drivers is a venture to the policemen and street safety officers. So the researchers have been continuously taking efforts on such type of sensors which are used for breath alcohol measurements. The primary benefit of this kind of sensors is the low cost and high sensitivity [36, 37]. The present work demonstrates the synthesis of ethanol sensor which plays a very important role to sense the breath alcohol. So we can control such kind of road accidents. This is the most important practical application for human being and his safety. The perovskite-undoped and -doped LaCrO3 is a great material for detecting gases such as H2S, acetone, and CO2, but the novelty of presented work is that the SnLaCrO3 shows high sensitivity at lower temperature, i.e., 150 °C, which is shown in Table 3.

This work has laid its emphasis on improving response, sensitivity, and selectivity through introducing tin oxide as a dopant. For this purpose, the sol–gel technique has been utilized for in situ synthesis. Moreover, the electrical, structural properties and its gas-sensing performance have been observed comparatively by varying the dopant concentration of tin. The thick films of all these doped nanostructures were prepared with the help of conventional screen printing method and then used for numerous toxic gases such as ammonia, CO2, ethanol, H2S, NO2, and acetone. All the information related to sensing was interpreted and compared to draw out the conclusion.

Materials and methods

Lanthanum nitrate [La(NO3)3], chromium nitrate [Cr(NO3)3], tin chloride [Sn(Cl2)∙2H2O] and citric acid utilized in this synthesis are AR grade bought from Merck Chemicals and Modern Laboratories, Nashik, India. All these chemicals were utilized without any further refinement.

Synthesis of Sn-doped LaCrO3 by sol–gel technique

We independently synthesized the Sn-doped LaCrO3 nanoparticles at differed concentrations by means of straightforward and easiest sol–gel technique. For this synthesis we followed the same procedure according to our prior work [20], the blend of lanthanum nitrate [La(NO3)3] precursor, chromium nitrate [Cr(NO3)3] precursor and tin chloride [Sn(Cl2)∙2H2O] precursor through utilizing variable concentrations of Sn (0.2 mol %, 0.4 mol %, 0.6 mol %, 0.8 mol %), and citric acid were used. The mixture of all four precursors was heated at 80 °C with continuous stirring on magnetic stirrer to evaporate distilled water for a minimum of 2–3 h. Through stirring, a homogeneous thick gel is obtained having fascinating shades of green color. This gel initially dried under IR lamp for 1–2 h. Then hard particles had been crushed, and afterward calcined for 5–6 h at 550 °C. We got a fine powder of Sn-doped LaCrO3 with various shades of greenish color at different concentrations.

Preparation of thick films of Sn-doped LaCrO3 nanoparticles

The thick film preparation method is a bit like our earlier work [20]. The powder of nanoparticle of Sn-doped LaCrO3 changed into a thixotropic stick which ended up as thick films by a basic screen printing approach. The inorganic to organic material proportion was maintained at 70:30. The inorganic part consists of nanomaterial (SnLaCrO3). The organic part consisted of 8% ethyl cellulose and 92% butyl carbitol acetate acts as a binder. The SnLaCrO3 with ethyl cellulose (EC) was mixed all together in an acetone medium with mortar and pestle. A solution of BCA was added dropwise till a thixotropic paste was accomplished. Lastly, the thick film was prepared on a glass substrate by making use of a standard screen printing method. The film was dried under IR lamp for 1 h to expel the organic volatile impurities and then fired at temperature 550 °C for 30 min in a muffle furnace. We have rehashed the same strategies for 0.2 M % Sn, 0.4 M % Sn, 0.6 M % Sn and 0.8 M % Sn individually.

Characterization techniques

The prepared compound was characterized in powder form for FTIR by means of the use of Shimadzu IR-affinity 1S. The XRD spectra of doped and undoped nanostructures were recorded by means of X-ray diffractometer Cu/40 kV/40 mA, from Goniometer: Ultima IV and X-ray diffractometer [Bruker D8, Advance, Germany] using CuKα radiation (λ = 1.5409 Å), respectively. The crystal structure was analyzed for the 2θ range from 20 to 80, the field emission scanning electron microscopy (SEM) was performed on FEI NOVA SEM 450 and transmission electron microscopy (TEM) was performed on SJeol/JSM 2100.

Results and discussion

X-ray diffraction (XRD)

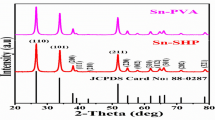

The X-ray diffraction pattern was recorded on-ray diffractometer Cu/40 kV/40 mA, from Goniometer: Ultima IV and X-ray diffractometer [Bruker D8, Advance, Germany] using CuKα radiation (λ = 1.5409 Å) to investigate the structural properties of the doped and undoped nanostructures. The spectrum was recorded by following the range of 2θ degrees between 20 and 80 to know the crystallite size and crystal structure of nanostructure. Figure 1a, b shows the XRD pattern of SnLaCrO3 nanostructure where the observed diffraction peaks of LaCrO3 correlated well with the reported data of LaCrO3 (JCPDS card no. 33-0701). It resembled the standard orthorhombic phase. The higher peak intensities of the XRD spectrum was because of better crystallinity with preferred orientation along the (121) plane. The average crystallite size was calculated by Debye–Scherer formula: \(D = \frac{K\lambda }{{\beta \;{\text{COS}}\;\theta }},\) where K is constant (0.89–1.39), λ is radiation of wavelength (1.54 A0), β is FWHM (full-width half-wave maxima), θ is the Bragg angle in degree, and D is the particle size. The crystallite size of undoped LaCrO3 was found to be 13.04 nm. But for doped nanostructure, it gets slightly increased. Typically for 0.2Sn size found to be 38.40 nm, for 0.4Sn it found to be 39.54 nm, for 0.6Sn and 0.8Sn size found to be 40.19 nm and 40.21 nm, respectively. It is well documented that as the dopant added in base material the grain size is increased [24]. The electronic conductivity of the ABO3 (Perovskite) type LaCrO3 is improved by doping with divalent ion on either A La (1.15 A) site or B Cr (0.67 A) site. Sn doping favors substitution at B site, i.e., chromium site as the ionic radii of Cr is close and slightly greater than Sn (0.71 A) so with substitution of Sn at chromium site the volume of the unit cell is increased as compared to undoped LaCrO3 and hence the crystallite size is increased with the concentration substituting Sn ion.

SEM analysis

A scanning electron microscope (SEM) is a type of electron microscope that produces images of a sample by scanning the surface with a targeted beam of electrons. This image demonstrates the surface texture and its porosity. Figure 2a–d shows the SEM images of Sn-doped LaCrO3 nanostructure with varying concentration of 0.2 mol %, 0.4 mol %, 0.6 mol %, 0.8 mol %, respectively, which was performed on FEI NOVA SEM 450. Images shown the agglomerated particles with different ranges that looks in random distribution and also shows the porous nature which is truly appropriate for sensing purpose because that voids can act as an adsorbent for different gaseous species [25, 26]. The particle size of synthesized Sn-doped LaCrO3 nanoparticles was observed to be between 27 and 33 nm for 0.2Sn, 25 and 38 nm for 0.4Sn, 26 and 40 nm for 0.6Sn and 26 and 43 nm for 0.8Sn with distorted spherical morphology. Scanning electron microscopy also revealed the increase in particle size as the concentration of Sn increased.

The specific surface areas of 0.2 M %, 0.4 M %, 0.6 M %, 0.8 M % Sn doped LaCrO3 films was calculated using BET method for spherical particles using following equation. The details of surface area, particles etc. is mentioned in Table 1.

where Sw is the surface area, 6 (six) is the constant, p is the composite density of the materials, d is the average particle size of functioning material.

Energy-dispersive X-ray spectroscopy (EDS)

The energy-dispersive X-ray spectroscopy was used to examine the elemental composition of both doped and undoped nanostructures. In the case of undoped LaCrO3, the sharp peak was found to be at 4.8 keV for lanthanum and at 5.4 keV for chromium in the EDS spectrum which we have presented previously. Figure 3a–d demonstrates the case of Sn-doped EDS spectrum, in which sharp peak was found to be at 4.8 keV for lanthanum, 5.4 keV for chromium and at 0.6, 3.4 keV for tin, all this information was obtained from EDS and for all concentration of Sn which is found to be near about same [20, 27, 28].

Also, Table 2 shows the elemental composition of doped and undoped nanostructures with respect to elemental weight percent.

Mapping

The mapping was also done to investigate the exact dopant concentration. Figure 4a–d clearly shows the concentration of Sn doped with LaCrO3. The figure showed that as the concentration of tin increased, the dot is also increased. That dot is nothing but the concentration of tin.

High-resolution transmission electron microscopy (HR-TEM)

The images by TEM (transmission electron microscopy) organized for 0.4% Sn-doped LaCrO3 nanostructure are shown in Fig. 5a, b. The images showed the spherical, rod-like and polycrystalline-shaped particles. These particles are well spread on the surface of the micrograph.

Selected area diffraction pattern (SAED)

SAED pattern (selected area electron diffraction) of 0.4 M % Sn-doped LaCrO3 nanostructure is shown in Fig. 5c; in SAED, the crystallinity of the sample is shown by the bright concentric spots. We can see that the bright spots were arranged in a ring-like pattern. These data which are obtained from SAED are combined with the diffraction data from XRD [29].

FT-IR analysis

On a basic level, FTIR examination in the material field is utilized to evaluate the useful functional groups that are the starching frequency of functional groups present in the synthesized material in relation to the documented compound [11]. The FTIR for undoped LaCrO3 nanostructure shows strong absorption bands at 594.08 cm−1 for La–O stretch and 420.48 cm−1 for Cr–O stretch [20]. In the case of Fig. 6, the La–O stretch is at 592–602 and for Cr–O, the wavenumber is observed at 416–430. The additional wavenumber is assigned for all Sn-doped with various concentrations which is shown in Fig. 6 at the range 771–773 cm−1. The wavenumber at 1486–1493 is observed as a water deformation peak. The peak observed at 2350–2400 is an H–O–H stretch for absorbed or free water [30].

Electrical properties

The Sn-doped LaCrO3 nanostructure, with its variable concentration, has been tested for electrical characterization so as to check its semiconducting nature. The semiconducting behavior of Sn-doped nanostructure has been checked in a closed glass-dome chamber by verifying electrical resistance with the help of static gas sensing system as shown in Fig. 7 by applying 30 V bias potential to the Sn-doped films and the cycle was performed without interference (i.e., the cycle becomes accomplished only in the presence of air from 350 to 40 °C temperature), of any gas. The test confirmed that with the increase in temperature there is a linear decrease in resistivity in the semiconducting behavior of all Sn-doped samples. The reason behind a decrease in resistivity with increment in temperature is the increment in the thermally activated drift mobility of charge carriers as per the hopping conduction mechanism [31, 32]. The temperature dependence of dc resistivity, i.e., its typical semiconducting behavior is shown in Fig. 8a–d for 0.2 M %Sn, 0.4 M %Sn, 0.6 M %Sn and 0.8 M %Sn, respectively.

Sensitivity and selectivity of Sn-doped LaCrO3

Gas sensing performance of Sn-doped LaCrO3 nanostructure thick films

Gas sensing was performed in a similar fashion by utilizing a static gas sensing system and by applying 30 V bias potential to films, as shown in Fig. 7. In this system, the oxide sensor is fixed in a closed glass chamber having a capacity of 15 L. While measuring the response (resistance) of the suitable sensor, the gas at ppm level is injected inside the glass chamber at a different temperature range from 50 to 400 °C. The resistance of the films was measured with the help of a digital multimeter. This measured resistance can help us to check the performance of various sensors. Using this device, the sensing performance of Sn-doped LaCrO3 nanostructures at all concentrations was calculated at different temperatures. The sensitivity of the 0.2 M %, 0.4 M %, 0.6 M %, and 0.8 M % Sn-doped LaCrO3 nanostructures was investigated using different gases such as CO2, ethanol, H2S, NH3, acetone, and NO2 using the following equation [33, 34]:

where Rg is the resistance of the thick films in the presence of gas and Ra is the resistance of the thick films in air.

The sensitivity for different gases such as H2S, NH3, ethanol, acetone, CO2, and NO2 for 0.2 M %, 0.4 M %, 0.6 M %, and 0.8 M % of Sn doped at fixed concentration, 1000 ppm, is shown in Fig. 9a–d, respectively. All figures interestingly demonstrated that the highest gas response was observed for ethanol at 150 °C in the presence of other gases for 0.4 M % Sn. The higher response may be assigned to films which had the optimum porosity and more effective surface area available to react to the species of gas.

The response is due to adsorption–desorption type of sensing mechanism [35]. The gas response for ethanol is based on the changes in resistance because of the amount of chemisorbed oxygen at the surface. At low temperature, the reaction products do not desorb from the sensor surface. The species cowl the sensing sites at the sensor surface, which prevents the further reaction among ethanol vapors and chemisorbed oxygen. Therefore, there might be an increase in resistance slightly. At most appropriate temperature, the reaction products become desorbed, allowing sensing sites on the sensor to react with new gas species. So this temperature is more effective for the reaction between ethanol vapors and chemisorbed oxygen. Subsequently, the resistance of the sensor increases significantly. Consequently, we got the highest response. At a temperature higher than the optimal temperature, the adsorbed gas begins to desorb. Fewer amounts of ethanol vapors react with chemisorbed oxygen, which leads to a small change in resistance of the sensor [38].

This response is varied for all concentrations of Sn-doped LaCrO3. As the concentration of Sn was slightly increased from 0.2 to 0.4 M %, the response was also slightly increased. But, as the Sn doping increased beyond 0.4–0.6 M and 0.8 M, the response was again diminished. The highest gas response for ethanol at 0.4 M % Sn of 84.18 was observed. Among ethanol and acetone, all four samples showed the response for H2S gas at 200 °C which was earlier recorded for base material LaCrO3 nanostructure. Figure 10a clearly shows the 100% selectivity for ethanol in the presence of other gases at 0.4 M %Sn as compared with other concentrations. Figure 10b shows ethanol sensing at various mole concentrations of Sn. The highest response was observed for ethanol at 0.4 M %Sn. Figure 10c shows the gas sensing response for 0.4 M %Sn at 150 °C at various concentrations of ethanol such as 1000 ppm, 500 ppm, 300 ppm, and 100 ppm. The gas response was registered as 84.18, 75.25, 62.33 and 53.75, respectively, at the above concentrations of ethanol.

Response and recovery

Response and recovery are significant parameters while studying the characteristics of the sensor. Sn-doped LaCrO3 nanostructure demonstrates the quick response in 41 s and recovery time is 37 s for ethanol as shown in Fig. 11.

Reproducibility

It is additionally one of the significant factors to confirm the stability of the sensor. For this confirmation, we performed the repeated cycles up to 45 days, i.e., one and a half months. We tested the 0.4 M %Sn-dopped LaCrO3 sensor at 1000 ppm of ethanol. As shown in Fig. 12, we saw that the gas response for 0.4 M %Sn is slightly diminished after a month as the concentration of gas remains the same. It implies no impressive change is observed even after the period of 45 days; henceforth, the material showed 97–98% response of its prior response. So we can confirm the stability of our sensor.

Conclusions

-

1.

The doped 0.2 M %Sn, 0.4 M %Sn, 0.6 M %Sn and 0.8 M %Sn with LaCrO3 nanostructure were prepared using a simple and cost-effective sol–gel technique. The thick films of all Sn-doped nanostructures were prepared by a conventional screen printing method.

-

2.

Characterization was done by means of XRD, from which crystallite size was calculated. For 0.2Sn, the size was observed to be 38.40 nm, for 0.4Sn, it was found to be 39.54 nm and for 0.6Sn and 0.8Sn, the sizes were found to be 40.19 nm and 40.21 nm, respectively. It implies that with the increase in the concentration of dopant, increase in the grain size takes place. Similarly, SEM revealed that increase in particle size takes place with the increase in the concentration of Sn.

-

3.

The Sn-doped LaCrO3 nanostructure at 0.2 M %Sn, 0.4 M %Sn, 0.6 M %Sn and 0.8 M %Sn concentration demonstrated higher gas response to ethanol for 0.4 M %Sn at 1000 ppm. The response was registered up to 84.18 at 150 °C.

-

4.

The best response to un-doped LaCrO3 nanostructure was registered for H2S gas at 200 °C temperature at 1000 ppm gas concentration.

-

5.

Addition of the dopant resulted in an increase in the gas response. Moreover, its influence on selectivity is noticed.

-

6.

Sn-doped LaCrO3 nanostructure showed quick response in 41 s and recovery time was 37 s for ethanol. Finally, the stability of sensor was proved with the help of reproducibility factor.

-

7.

The perovskite-undoped and -doped LaCrO3 is a great material for detecting the gases such as H2S, acetone, CO2, but novelty of the presented work is that the SnLaCrO3 shows lower operating temperature, i.e., 150 °C, than others which is shown in Table 3.

Table 3 Comparative gas response of pure LaCrO3 and doped LaCrO3 at various temperature

References

Patil, R.P., More, P.V., Jain, G.H., Khanna, P.K., Gaikwad, B.: BaTiO3 Nanostructures for H2S gas sensor: influence of band-gap, size and shape on sensing mechanism. Els. Vac. 146, 455–461 (2017)

Li, B.W., Osada, M., Kim, Y.H., Ebina, Y., Akatsuka, K., Sasaki, T.: Atomic layer engineering of high-κ ferroelectricity in 2D perovskites. J. Am. Chem. Soci. 139, 10868–10874 (2017)

Tsai, H., Asadpour, R., Blancon, J.C., Stoumpos, C.C., Ajayan, P.M., Nie, W.: Design principles for electronic charge transport in solution-processed vertically stacked 2D perovskite quantum wells. Nat. Comm. 9, 2130 (2019)

Ali, S.M., Lehaibi, H.A.: Smart perovskite sensors: the electrocatalytic activity of SrPdO for hydrazine oxidation. J. Electr. Soci. 165(9), B345–B350 (2018)

Kakavelakis, G., Petromichelaki, V., Gagaoudakis, E., Binas, V., Kiriakidis, G., Petridis, K., et al.: Solution processed CH3NH3PbI3-xCl perovskite based self-powered ozone sensing element operated at room temperature. ACS Sen. 3, 135–142 (2018)

Borchani, S.M., Koubaa, W.C.R., Megdiche, M.: Structural, magnetic and electrical properties of a new double-perovskite LaNaMnMoO6 material. Roy. Soci. Open Sci. 4, 170920 (2017)

Casallas, F., Vera, E., Landinez, D., Parra, C., Roa, J.: Structural properties, electric response and magnetic behaviour of La2SrFe2CoO9 triple complex perovskite. J. Phy. Conf. Ser. 687, 012047 (2016)

Costa, A.C.S., Peres, A.P.S., Lima, A.C., Bergamann, C.P., Acchar, W.: Synthesis and characterization of LaCr1-xSnxO3 nanopowders. Mate. Sci. Forum 881, 3–6 (2016)

Lao, X., Yang, Z., Su, Z., Wang, Z., Ye, H., Wang, M., et al.: Luminescence and thermal behaviors of free and trapped excitons in cesium lead halide perovskite nanosheets. Nano 10, 9949–9956 (2018)

Situmeang, R., Supriyanto, R., Septanto, M., Simanjuntak, W., Sembiring, S., Roger, A.C.: NixCoyFe1-x-yO4 nanocatalyst: preparation, characterization and catalytic activity in CO2/H2 conversion. Proce. Confe. 2, 103–110 (2013)

Situmeng, R.T.: Pectins as emulsifying agent on the preparation, characterization, and photocatalysis of nano-LaCrO3 (2019). https://doi.org/10.5772/intechopen.83625

Li, J., Wu, Q., Wu, J.: Synthesis of nanoparticles via solvothermal and hydrothermal methods, Hand. of nanop, pp. 1–28. Springer international publishing, Swizerland (2015)

Rivas-Vázquez, L.P., Rendón-Angeles, J.C., Rodríguez-Galicia, J.L., Gutiérrez-Chavarria, C.A., Zhu, K.J., Yanagisawa, K.: Preparation of calcium doped LaCrO3 fine powder by hydrothermal method and its sintering. J. Euro. Cera. Soci. 26(1–2), 81–88 (2006)

Kumar, S., Teraoka, Y., Joshi, A.G., Rayalu, S., Labhsetwar, N.J.: Ag promoted La0.8Ba0.2MnO3 type perovskite catalyst for N2O decomposition in the presence of O2, NO and H2O. J. Mol. Cata. 348(1–2), 42–54 (2011)

Yanping, W., Junwu, Z., Xiaojie, S., Xujie, Y.: Solution-phase synthesis and characterization of perovskite LaCoO3 nanocrystals via a co-precipitation route. J. Rar. Ear. 25(5), 601–604 (2007)

Doggali, P., Rayalu, S., Teraoka, Y., Labhsetwar, N.: Effect of A-site substitution in perovskites: catalytic properties of PrMnO3 and Ba/K/Ce substituted PrMnO3 for CO and PM oxidation. J. Envir. Chem. Engine. 3(1), 420–428 (2015)

Adole, V.A., Pawar, T.B., Koli, P.B., Jagdale, B.S.: Exploration of catalytic performance of nano-La2O3 as an efficient catalyst for dihydropyrimidinone/thione synthesis and gas sensing. J. Nanost. Chem. 9, 61–76 (2019)

Situmeang, R., Manurung, P., Sulistiyo, S.T., Hadi, S., Simanjuntak, W., Sembiring, S.: Sol-gel method for preparation of nanosize NiFe2-xCoxO4 using egg white. Asi. J. Chem. 27(3), 1138–1142 (2015)

Girish, H.N., Shao, G.Q., Basavalingu, B.: Well- Monocrystallized LaCrO3 Particles from LaCrO4 precursor by supercritical hydrothermal technique. Roy. Soci. Chem. 6(83), 79763–79767 (2016)

Shinde, V.S., Kapadnis, K.H., Sawant, C.P.: Synthesis, structural characterization of LaCrO3 nanostructure and it’s gas sensing applications. J. Emer. Techn. Inno. Res. (JETIR) 5(12), 546–556 (2018)

Siemons, M., Leifter, A., Simon, U.: Preparation and gas sensing characteristics of nanoparticulate p-type semiconducting LnFeO3 and LnCrO3 materials. Adv. Funct. Mat. 17, 2189–2197 (2007)

Rajgure, A.V., Tarwal, N.L., Patil, J.Y., Chikhale, L.P., Pawar, R.C., Lee, C.S., Mulla, I.S., Suryavanshi, S.S.: Gas sensing performance of hydrothermally grown CeO2–ZnO composites. Cera. Inter. 40, 5837–5842 (2014)

Thakare, K., Patil, S., Deshmukh, S., Borse, R., Ahire, R.: Preparation, characterization and gas sensing performance of pure SnO2 thin films deposited using physical vapour deposition technique. IRA-Inter. J. Tech. Eng. 4(2), 103–116 (2016)

Patil, R.P., Hiragond, C., More, P.V., Jain, G.H., Khanna, P.K., Gaikwad, V.B.: La doped BaTiO3 nanostructures for room temperature sensing of NO2/NH3: focus on la concentration and sensing mechanism. Els. Vacc. 146, 455–461 (2019)

Xu, Y., Sun, D., Hao, H., Gao, D., Sun, Y.: Non-stoichiometric Co (II), Ni(II), Zn(II) ferrite nanospheres: size controllable synthesis, excellent gas-sensing and Magnetic properties. RSC Adv. 6, 98994–99002 (2016)

Mondal, S., Kumari, M., Madhuri, R., Sharma, P.K.: Acetaminophen and acetone sensing capabilities of nickel ferrite nanostructures. Appl. Phys. A 123(494), 1–15 (2017)

Koli, P.B., Kapadnis, H.K., Deshpande, U.G.: Nanocrystalline-modified nickel ferrite films: an effective sensor for industrial and environmental gas pollutant detection. J. Nano. Chem. 9, 95–110 (2019)

Ishaq, K., Saka, A.A., Kamardeen, A.O., Ahmed, A., Alhassan, M.I., Abdullahi, H.: Characterization and antibacterial activity of nickel ferrite doped aluminium ananoparticle. Eng. Sci. Technol. Int. J. 20, 563–569 (2017)

Koli, P.B., Kapadnis, H.K., Deshpande, U.G.: Fabrication and characterization of pure and modified Co3O4 nanocatalyst and their application for photocatalytic degradation of eosine blue dye: a comparative study. J. Nano. In Chem. 8, 453–463 (2018)

Babadi, N., Tavakkoli, H., Afshari, M.: Synthesis and characterization of Nanocomposite NiFe2O4 Salen Si and its application in efficient removal of Ni(II) from aqueous solution. Bull. Chem. Soc. Ethiop. 32(1), 77–88 (2018)

Nitya, V.D., Immanuel, R.J., Senthikumar, S.T., Sanjeeviraja, C., Perelshtein, I., Zitoun, D., Selven, R.K.: Studies on the structural, electrical and magnetic properties of LaCrO3, LaCr0.5Cu0.5O3 and LaCr0.5Fe0.5O3 by sol–gel method. Mat. Rese. Bull. 47, 1861–1868 (2012)

Patil, Choughule, B.K.: Effect of resistivity on magnetoelectric effect in (X) NiFe2O4-(1–x) Ba 0.9 Sr0.1 TiO3 ME composites. J. Alloc. Compon. 470(1–2), 531–535 (2009)

Deshmukh, S.B., Lad, U.D., Hiray, R.P., Patil, G.E., Bari, R.H.: NiO Modified ZrO2 thick film resistor as H2S gas sensor. Reser. Jour. Inter. Multidisci. E-Res. J. I, 61–72 (2016)

Deore, M.K., Jain, G.H.: Synthesis, Characterization and gas sensing application of sNano ZnO material. Int. J. Nano. 7(1), 57–72 (2014)

Qi, J., Zhang, H., Lu, S., Li, X., Xu, M., Zhang, Y.: High performance indium doped ZnO gas sensor. J. Nano. 2015, 1–6 (2014)

Gbenga, D.E., Hamed, H.I., Lateef, A.A., Opeyemi, A.E.: Alcohol detection of drunk drivers with automatic car engine locking system. Nova J. Eng. App. Sci. 6, 1–15 (2017)

Liu, X., Cheng, S., Liu, H., Hu, S., Zhang, D., Ning, H.: A survey on gas sensing technology. Sensors 12, 9635–9665 (2012)

Khetre, S.M., Khilare, C.J., Shivankar, V.S., Bamane, S.R.: Preparation and study of acetone gas sensing behavior nanocrystalline LaCrO3 thick films. J. Sen.Trans. 137, 165–175 (2012)

Kadu, A.V., Bobade, A.B., Bobade, A.B., Chaudhari, G.N.: Structural Characterization of nanocrystalline La1–xSrxCrO3 Thick films for H2S gas sensor. J. Sen. Tech. 2, 13–18 (2012)

Chen, Y., Qin, H., Shi, C., Li, LHu: High temperature CO2 sensing properties and mechanism of nanocrystalline LaCrO3 with rhombohedral structure: experiments and ab initio calculations. J. RSC Adv. 5, 547109 (2015)

Acknowledgements

Authors gratefully acknowledged the Physics Department of SPPU University, Pune, for XRD, also CIF SPPU University, Pune, for XRD and SEM studies. Authors are thankful to STIC, Cochin, India, for TEM, Authors are also thankful to the instrumentation center of K.T.H.M College, Nashik, for FTIR studies and are also thankful to the Department of Chemistry, G.T. Patil College, Nandurbar, Department of Chemistry L.V.H. College, Panchavati, Nashik, and Department of Chemistry, K.T.H.M. College, Nashik.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Open Access This article is distributed under the terms of the Creative Commons Attribution 4.0 International License (http://creativecommons.org/licenses/by/4.0/), which permits unrestricted use, distribution, and reproduction in any medium, provided you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made.

About this article

Cite this article

Shinde, V.S., Sawant, C.P. & Kapadnis, K.H. Modified Sn-doped LaCrO3 nanostructures: focus on their characterization and applications as ethanol sensor at a lower temperature. J Nanostruct Chem 9, 231–245 (2019). https://doi.org/10.1007/s40097-019-00314-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40097-019-00314-z