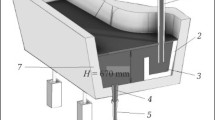

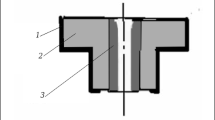

We consider various types of design of the refractory equipment for the chambers of tundish ladles of continuous casting machines (CCM). The improvement of the equipment guarantees the efficient formation of metal flows and creates conditions for the improvement of its quality. We estimate the serviceability of partitions and baffles existing for the tundish ladles of CCM: their strength, the absence of cavitation, and the condition according to which the velocity of steel on the metal – slag interface must be lower than the permissible velocity.

Similar content being viewed by others

References

V. A. Efimov and A. Él’darkhanov, Contemporary Metallurgical Technologies [in Russian], Novye Tekhnologii, Moscow (2004).

K. N. Vdovin, Vik. V. Tochilkin, and Vas. V. Tochilkin, “Technologies for controlling flows of steel and the development of refractory structures for the tundish of a four-strand continuous caster,” Refract. Ind. Ceram., 57(1), 6 – 8 (2016).

V. N. Gushchin and V. A. Ul’yanov, “Improved tundish refining of steel in continuous-casting machines,” Steel Transl., 47(5), 320 – 324 (2017).

I. V. Bondarenko, E. M. Alekseev, K. V. Baranchikov, et al., “Mastering of the technology of manufacturing of round cast billets from wheel steel intended for the production of all-rolled railroad wheels,” Byul. “Chern. Metall.,” No. 5, 22 – 24 (2015).

K. N. Vdovin, E. A. Melnichuk, A. V. Nefedov, et al., “Intake chamber of the tundish in a continuous slab-casting machine,” Steel Transl., 44(3), 186 – 189 (2014).

J. P. Rogler, L. J. Heaslip, and M. Mehrvar, “Inclusion removal in a tundish by gas dubbing,” Can. Met. Quart., 43(3), 407 – 415 (2004).

I. D. Kashcheev, S. A. Pomortsev, and A. A. Ryaplova, “Developing refractory concretes of alumosilicate- and alumina-based compositions for high-temperature equipment in ferrous metallurgy,” Refract. Ind. Ceram., 55(4), 281 – 284 (2014).

A. L. Sotnikov, “Diagnostics of the electromechanical drive of a swing mechanism of the mold of a continuous casting machine,” Izv. Vysch. Uchebn. Zaved., Chern. Metall.,59(5), 334 – 338 (2016).

K. N. Vdovin, Vas. V. Tochilkin, O. A. Filatova, et al., “Improvement of the process of metal casting and the design of refractory equipment of the “tundish ladle – open jet – mold” system of a continuous billet-casting machine,” Refract. Ind. Ceram., 59(3), 237 – 240 (2018).

A. V. Kuklev, V. V. Tinyakov, Yu. M. Aizin, et al., “Optimization of the hydrodynamic characteristics of tundishes in order to remove exogeneous nonmetallic inclusions, Metallurgist, 48(3–4), 153 – 157 (2004).

Prospects of investigations of high-speed continuous casting of conventional slabs from carbon steels,” Chermetinform. Prilozh. “Novosti Chern. Metall. za Rubezhom,” No. 4, 20 – 27 (2002).

K. N. Vdovin, V. V. Tochilkin, and I. M. Yachikov, Continuous Casting of Steel. Hydromechanics of Continuous Casting Machines: Monograph [in Russian]. Nosov Magnitogorsk State Technical University, Magnitogorsk (2014).

K. N. Vdovin, V. V. Tochilkin, M. V. Semenov, et al., “Refining of metal in tundish ladles,” Vestn. Nosov Magnitogorsk. Gos. Tekh. Univ., No. 1, 43 – 46 (2007).

K. N. Vdovin, Vas. V. Tochilkin, V. I. Umnov, et al., “Improving refractory constructions in the system ‘steel – pouring ladle – pouring basket’ of CCM,” Refract. Ind. Ceram.,58(3),255 – 258 (2017).

K. N. Vdovin, Vas. V. Tochilkin, O. A. Filatova, et al., “Synthesis of the process of casting of metals and structures of the refractory equipment of the ‘steel-pouring ladle – tundish of the continuous casting machine’ system,” Novye Ogneupory, No. 8, 9 – 13 (2018).

V. N. Gushchin, V. A. Ul’yanov, and V. A. Vasiliev, “Technical solutions for controlling flows of melts in the tundishes of continuous casters,” Metallurgist, 54(9–10), 591 – 593 (2011).

H.-J. Odenthal, R. Bolling, and H. Pfeifer, “Numerical and physical simulation of tundish flow phenomena,” Steel Res. Int., 74(1), 20, 44 – 55 (2002).

K. N. Vdovin, V. V. Tochilkin, M. V. Semenov, et al., “Refining of metals in tundish ladles,” Vestn. Nosov Magnitogorsk. Gos. Tekh. Univ., No. 1, 43 – 46 (2007).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Vdovin, K.N., Tochilkin, V.V., Filatova, O.A. et al. Design and Methods for the Numerical Analyses of the Refractory Equipment of Tundish Ladle of a Continuous Casting Machine. Refract Ind Ceram 60, 323–326 (2019). https://doi.org/10.1007/s11148-019-00361-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-019-00361-7