Abstract

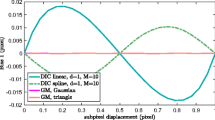

Users of full-field measurement methods like Digital Image Correlation (DIC) often aim to perform measurements with the best trade-off between spatial resolution, bias and measurement resolution. Whenever two full-field methods are compared, it is essential that these criteria are taken into consideration. Recently a metrological efficiency indicator for full-field measurements has been proposed and discussed. This indicator combines measurement resolution and spatial resolution. It has been shown to be invariant to the subset size in the case of Local DIC. The goal of this article is to discuss a method, which determines both the spatial and the measurement resolutions for a given bias for two different DIC methods, in order to obtain the metrological efficiency indicator for each of these methods. The benefit of this indicator is that it does not depend on setting parameters such as the subset size, which are chosen by the user. As such, it can be considered as intrinsic to each technique, thus enabling fair comparison. Local DIC and triangular finite element based Global DIC will be the subject of this investigation. With this setting, their respective subset and triangular element sizes will be related to the spatial resolution of both methods for a given acceptable bias. By using the metrological efficiency indicator, the performance of the two methods will be compared and discussed to a new level of detail. Generally speaking, the indicator shows that the metrological performance of both methods is similar, confirming their popularity. However, it will be shown that, depending on the choice of what an acceptable bias is, one of the method may be preferred to another. The results show that for the specific DIC versions used in the study, for cases for which a significant bias is acceptable, Local DIC outperforms Global DIC, while the opposite is true in the case for which the bias requirements are more stringent. Finally, the quadratic versions of both DIC versions are shown to significantly outperform their respective linear versions.

Similar content being viewed by others

References

Lucas BD, Kanade T (1981) An iterative image registration technique with an application to stereo vision. In: Proceedings of the 7th International Joint Conference on Artificial Intelligence - Volume 2, IJCAI’81. Morgan Kaufmann Publishers Inc, San Francisco, pp 674–679

Sutton MA, Wolters WJ, Peters WH, Ranson WF, McNeill SR (1983) Determination of displacements using an improved digital correlation method. Image Vis Comput 1(3):133–139

Sutton MA, Mingqi C, Peters WH, Chao YJ, McNeill SR (1986) Application of an optimized digital correlation method to planar deformation analysis. Image Vis Comput 4(3):143–150

Blaysat B, Grédiac M, Sur F (2016) Effect of interpolation on noise propagation from images to DIC displacement maps. Int J Numer Methods Eng 108(3):213–232

Blaysat B, Grédiac M, Sur F (2016) On the propagation of camera sensor noise to displacement maps obtained by DIC - an experimental study. Exp Mech 56(6):919–944

Baldi A, Bertolino F (2015) Experimental analysis of the errors due to polynomial interpolation in digital image correlation. Strain, pp 248–263

Ke XD, Schreier HW, Sutton MA, Wang YQ (2011) On error assessment in stereo-based deformation measurements. Exp Mech 51(4):423–441

Wang YQ, Sutton MA, Bruck HA, Schreier HW (2009) Quantitative error assessment in pattern matching Effects of intensity pattern noise, interpolation, strain and image contrast on motion measurements. Strain 45(2):160–178

Wang YQ, Sutton MA, Ke XD, Schreier HW, Reu PL, Miller TJ (2011) On error assessment in stereo-based deformation measurements. Exp Mech 51(4):405–422

Schreier HW, Sutton MA (2002) Systematic errors in digital image correlation due to undermatched subset shape functions. Exp Mech 42(3):303–310

Sutton MA, McNeill SR, Jang J, Babai M (1988) Effects of subpixel image restoration on digital correlation error estimates. Opt Eng 27(10):870–877

Wang B, Pan B (2015) Random errors in digital image correlation due to matched or overmatched shape functions. Exp Mech 55(9):1717–1727

Pan B (2013) Bias error reduction of digital image correlation using gaussian pre-filtering. Opt Lasers Eng 51(10):1161–1167

Pan B, Yu L, Wu D, Tang L (2013) Systematic errors in two-dimensional digital image correlation due to lens distortion. Optics and Lasers in Engineering 51(2):140–147, 2

Xu X, Su Y, Zhang Q (2017) Theoretical estimation of systematic errors in local deformation measurements using digital image correlation. Optics and Lasers in Engineering 88:265–279, 1

Grédiac M, Sur F (2014) Effect of sensor noise on the resolution and spatial resolution of displacement and strain maps estimated with the grid method. Strain 50(1):1–27

Grédiac M, Blaysat B, Sur F (2017) A critical comparison of some metrological parameters characterizing local digital image correlation and grid method. Exp Mech 57(6):871–903

Roux S, Hild F, Berthaud Y (2002) Correlation image velocimetry: A spectral approach. Appl Opt 41 (1):108–115

Sun Y, Pang JHL, Wong CK, Su F (2005) Finite element formulation for a digital image correlation method. Appl Opt 44(34):7357–7363

Besnard G, Hild F, Roux S (2006) Finite-element displacement fields analysis from digital images: application to portevin-Le châtelier bands. Exp Mech 46(6):789–803

Mathieu F, Leclerc H, Hild F, Roux S (2015) Estimation of elastoplastic parameters via weighted FEMU and integrated-DIC. Exp Mech 55(1):105–119

Ruybalid AP, Hoefnagels JPM, van der Sluis O, Geers MGD (2016) Comparison of the identification performance of conventional FEM updating and integrated DIC. Int J Numer Methods Eng 106(4):298–320

Hild F, Roux S (2012) Comparison of local and global approaches to digital image correlation. Exp Mech 52:1503–1519

Pan B, Wang B, Lubineau G, Moussawi A (2015) Comparison of subset-based local and finite element-based global digital image correlation. Exp Mech 55(5):887–901

Wittevrongel L, Lava P, Lomov SV, Debruyne D (2015) A self adaptive global digital image correlation algorithm. Exp Mech 55(2):361–378

Grédiac M, Sur F, Blaysat B (2016) The grid method for in-plane displacement and strain measurement: a review and analysis. Strain 52(3):205–243

Patterson EA, Hack E, Brailly P, Burguete RL, Saleeme Q, Siebert T, Tomlinsone RA, Whelan MP (2007) Calibration and evaluation of optical systems for full-field strain measurement. Opt Lasers Eng 45(5):550–564

Hack E, Lampeas G, Mottershead JE, Patterson EA, Siebert T, Whelan MP (2011) Progress in developing a standard for dynamic strain analysis. In: Experimental and Applied Mechanics, volume 6 of Conference Proceedings of the Society for Experimental Mechanics Series, pp 425–429

Sebastian C, Lin X, Hack E, Patterson E (2015) A reference material for establishing uncertainty for static and dynamic displacements. In: Proceedings of the SEM Conference, Costa Mesa, CA, USA

Hack E, Lin X, Patterson EA, Sebastian CM (2015) A reference material for establishing uncertainties in full-field displacement measurements. Measurement Science and Technology 26(7):075004

(2010) Standard guide for evaluating non-contacting optical strain measurement systems, ASTM standard E2208-02

(2018) ASD-STAN. prEN 4861 P1, Aerospace series-Metrological assessment procedure for kinematic fields measured by digital image correlation. Technical report

Sutton MA, Orteu JJ, Schreier H (2009) Image correlation for shape, motion and deformation measurements: Basic Concepts, Theory and Applications. Springer

Tong W (2013) Reduction of noise-induced bias in displacement estimation by linear off-pixel digital image correlation. Strain 49(2):158–166

Wang ZY, Li HQ, Tong JW, Ruan JT (2007) Statistical analysis of the effect of intensity pattern noise on the displacement measurement precision of digital image correlation using self-correlated images. Exp Mech 47 (5):701–707

Réthoré J, Besnard G, Vivier G, Hild F, Roux S (2008) Experimental investigation of localized phenomena using digital image correlation. Phil Mag 88(28-29):3339–3355

Réthoré J, Hild F, Roux S (2008) Extended digital image correlation with crack shape optimization. Int J Numer Methods Eng 73(2):248–272

Roux S, Hild F (2006) Stress intensity factor measurements from digital image correlation: post-processing and integrated approaches. Int J Fract 140:141–157

Grédiac M, Sur F, Badulescu C, Mathias J-D (2013) Using deconvolution to improve the metrological performance of the grid method. Opt Lasers Eng 51(6):716–734

Sur F, Blaysat B, Grédiac M (2018) Rendering deformed speckle images with a boolean model. Journal of Mathematical Imaging and Vision 60(5):634–650

SEM - DIC challenge. http://sem.org/dicchallenge

Reu P, Blaysat B, Jones E, Helm J (2019) Update on the dic challenge 2.0 and the stereo-dic challenge. In: SEM Conference, Reno, USA

Foi A, Trimeche M, Katkovnik V, Egiazarian K (2008) Practical poissonian-Gaussian noise modeling and fitting for single-image raw-data. IEEE Trans Image Process 17(10):1737–1754

Pan B, Xie H, Wang Z (2010) Equivalence of digital image correlation criteria for pattern matching. Appl Opt 49(28):5501–5509

Tong W (2013) Formulation of lucas–kanade digital image correlation algorithms for non-contact deformation measurements: a review. Strain 49(4):313–334

Pan B, Wang B (2016) Digital image correlation with enhanced accuracy and efficiency: a comparison of two subpixel registration algorithms. Exp Mech 56(8):1395–1409

Neggers J, Blaysat B, Hoefnagels JPM, Geers MGD (2016) On image gradients in digital image correlation. Int J Numer Methods Eng 105(4):243–260

Passieux J-C, Bouclier R (2019) Classic and inverse compositional Gauss-Newton in global DIC. Int J Numer Methods Eng 119:453–468. https://doi.org/10.1002/nme.6057

Huang J, Pan X, Peng X, Yuan Y, Xiong C, Fang J, Yuan F (2013) Digital image correlation with self-adaptive gaussian windows. Exp Mech 53(3):505–512

Valle V, Hedan S, Cosenza P, Fauchille AL, Berdjane M (2015) Digital image correlation development for the study of materials including multiple crossing cracks. Exp Mech 55(2):379–391

Grédiac M, Blaysat B, Sur F (2019) A robust-to-noise deconvolution algorithm to enhance displacement and strain maps obtained with local dic and lsa. Exp Mech 59(2):219–243

Fedele R, Galantucci L, Ciani A (2013) Global 2D digital image correlation for motion estimation in a finite element framework: a variational formulation and a regularized, pyramidal, multi-grid implementation. Int J Numer Methods Eng 96(12):739–762

Neggers J, Hoefnagels JPM, Hild F, Roux S, Geers MGD (2012) A global digital image correlation enhanced full-field bulge test method. Procedia IUTAM 4(0):73–81

Dufour J-E, Hild F, Roux S (2014) Integrated digital image correlation for the evaluation and correction of optical distortions. Opt Lasers Eng 56(0):121–133

Kleinendorst SM, Hoefnagels JPM, Verhoosel CV, Ruybalid AP (2015) On the use of adaptive refinement in isogeometric digitalimage correlation. Int J Numer Methods Eng 104(10):944–962

Rupil J, Roux S, Hild F, Vincent Ludovic (2011) Fatigue microcrack detection with digital image correlation. The Journal of Strain Analysis for Engineering Design 46(6):492–509

Mathieu F, Hild F, Roux S (2012) Identification of a crack propagation law by digital image correlation. International Journal of Fatigue 36(1):146–154

Blaysat B, Hoefnagels JPM, Lubineau G, Alfano M, Geers MGD (2015) Interface debonding characterization by image correlation integrated with double cantilever beam kinematics. Int J Solids Struct 55:79–91

Réthoré J (2010) A fully integrated noise robust strategy for the identification of constitutive laws from digital images. Int J Numer Methods Eng 84(6):631–660

Gras R, Leclerc H, Roux S, Otin S, Schneider J, Périé J-NN (2012) Identification of the out-of-plane shear modulus of a 3d woven composite. Exp Mech, pp 1–12

Passieux J-C, Bugarin F, David C, Périé J-N, Robert L (2015) Multiscale displacement field measurement using digital image correlation: Application to the identification of elastic properties. Exp Mech 55 (1):121–137

Neggers J, Hoefnagels JPM, Geers MGD, Hild F, Roux S (2015) Time-resolved integrated digital image correlation. Int J Numer Methods Eng 103(3):157–182

Neggers J, Hoefnagels JPM, Hild F, Roux S, Geers MGD (2014) Direct stress-strain measurements from bulged membranes using topography image correlation. Exp Mech 54(5):717–727

Baldi A, Bertolino F (2016) Assessment of h-refinement procedure for global digital image correlation. Meccanica 51(4):979–991

Sur F, Grédiac M (2016) Influence of the analysis window on the metrological performance of the grid method. Journal of Mathematical Imaging and Vision 56(3):472–498

Grédiac M, Blaysat B, Sur F (2019) On the optimal pattern for displacement field measurement: random speckle and DIC, or checkerboard and LSA?

JCGM Member Organizations (2012) International vocabulary of metrology – Basic and general concepts and associated terms (VIM), volume 200 BIPM

Chrysochoos A, Surrel Y (2012) Chapter 1. Basics of metrology and introduction to techniques. In: Grédiac M, Hild F (eds) Full-field Measurements and Identification in Solid Mechanics, Wiley, pp 1–29

Bornert M, Brémand F, Doumalin P, Dupré JC, Fazzini M, Grédiac M, Hild F, Mistou S, Molimard J, Orteu JJ, Robert L, Surrel Y, Vacher P, Wattrisse B (2009) Assessment of digital image correlation measurement errors Methodology and results. Exp Mech 49:353–370

Blaber J, Adair B, Antoniou A (2015) . Ncorr: Open-source 2d digital image correlation matlab software 55(6):1105–1122

Acknowledgements

The authors are grateful to the French National Research Agency (ANR) for their financial support (ICAReS project, N∘ANR-18-CE08-0028-01).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher’s Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Appendix: Appendix: Vocabulary and definitions

Appendix: Appendix: Vocabulary and definitions

Three metrological parameters are discussed in this paper, namely the measurement resolution, the bias and the spatial resolution. Their definition, already given in [17, 69] , are recalled below for the sake of complitness:

Measurement resolution: in Ref. [70], the measurement resolution is defined by the smallest change in a quantity being measured that causes a perceptible change in the corresponding indication. More precisely, it is proposed in [71] to define it as the change in quantity being measured that causes a change in the corresponding indication greater than one standard deviation of the measurement noise, which enables us to quantify the measurement resolution. This definition is quite arbitrary, any other (reasonable) multiple of the standard deviation being also potentially acceptable, but the idea is that the resolution quantifies the smallest change not likely to be caused by measurement noise [71].

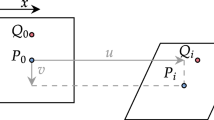

Spatial resolution: the spatial resolution denoted by ℓλ is defined here by the lowest period of a sinusoidal deformation that the technique is able to reproduce before losing a certain percentage λ of amplitude, this quantity being chosen a priori [25]. The advantage of this definition is that it is not based on an arbitrary value for the subset size in Local DIC or for the elements size in Global DIC. This makes it possible to compare the spatial resolution between these two techniques.

Bias: a systematic error generally occurs when a given technique returns actual details in displacement and strain maps. It is due to the fact that the amplitude of such apparent details is generally lower than the amplitude of the actual detail. This apparent “damping” is a bias, which can be quantified by considering a sinusoidal reference displacement field, and measuring the relative loss of amplitude exhibited by the displacement field returned by the technique under study, as suggested in Refs. [25, 44, 72, 73]. Of course, the loss of amplitude depends on the frequency f of the sine function. This loss of amplitude is denoted here by l(f). In this context, the spatial resolution defined above is defined for a given bias λ, the relation between ℓλ and λ being that ℓλ is the smallest value such that l(1/ℓλ) = λ. We call here λ the bias of the method. This is a slight abuse of language since fixing λ does not mean that the damping of any displacement or strain field is actually equal to this λ value. Note finally that for DIC, the effect quantified here by λ is often referred to as the “matching bias”, because it occurs when there is a mismatch between the matching function used to describe the displacement within subsets on the one hand, and the degree of the actual displacement if the latter is described by a polynomial on the other hand.

Rights and permissions

About this article

Cite this article

Blaysat, B., Neggers, J., Grédiac, M. et al. Towards Criteria Characterizing the Metrological Performance of Full-field Measurement Techniques. Exp Mech 60, 393–407 (2020). https://doi.org/10.1007/s11340-019-00566-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11340-019-00566-4