Abstract

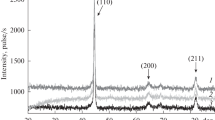

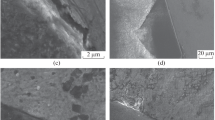

The processes of structure formation, mechanical and tribological properties under vacuum hot pressing of a blend of powders of iron, copper, nickel and tin with a dispersion of 5–50 µm with the addition of a nanopowder of vanadium nitride depending on temperature are described. It was found that an increase in sintering temperature from 800 to 1000°C leads to grinding of ferrite grains to 20–400 nm, the release of primary (d = 10–100 nm) and secondary (d ≤ 10 nm) VN grains and an increase in hardness from 3.75 to 5.37 GPa and H/E parameters from 0.021 to 0.043 and H3/E2 from 1.70 to 9.91 MPa, a decrease in the elastic modulus from 176 to 125 GPa and a friction force from 250 to 180 mN, a decrease in speed wear from 8.15 × 10−4 to 1.79 × 10−4 mm3·N−1·m−1. The mechanism of grain refinement and the improvement of physical and mechanical properties is due to α → γ → α transformations occurring under conditions of VN dissolution in α-Fe and subsequent cooling.

Similar content being viewed by others

References

Mechnik, V.A., Bondarenko, N.A., Kuzin, N.O., and Lyashenko, B.A., The role of structure formation in forming the physicomechanical properties of composites of the diamond-(Fe-Cu-Ni-Sn) system, J. Frict. Wear, 2016, vol. 37, no. 4, pp. 377–384.

Zaitsev, A.A., Sidorenko, D.A., Levashov, E.A., Kurbatkina, V.V., Rupasov, S.I., Andreev, V.A., and Sevast’yanov, P. V., Development and application of the Cu-Ni-Fe-Sn-based dispersion-hardened bond for cutting tools of superhard materials, J. Superhard Mater., 2012, vol. 34, no. 4, pp. 270–280.

Mechnyk, V.A. Diamond-Fe-Cu-Ni-Sn composite materials with predictable stable characteristics, Mater. Sci., 2013, vol. 48, no. 5, pp. 591–600.

Gevorkyan, E., Mechnik, V., Bondarenko, N., Vovk, R., Lytovchenko, S., Chishkala, V., and Melnik, O., Peculiarities of obtaining diamond-(Fe-Cu-Ni-Sn) composite materials by hot pressing, Functional Mater., 2017, vol. 24, no. 1, pp. 31–45.

Konstanty, J., Powder metallurgy diamond tools, UK, Oxford: Elsevier Science, 2005.

Dinaharan, I., Sathiskumar, R., and Murugan, N., Effect of ceramic particulate type on microstructure and properties of copper matrix composites synthesized by friction stir processing, J. Mater. Res. Technol., 2016, vol. 5, no. 4, pp. 302–316.

Shabani, M., Paydar, M.H., Zamiri, R., Goodarzi, M., and Moshksar, M.M., Microstructural and sliding wear behavior of SiC-particle reinforced copper matrix composites fabricated by sintering and sinter-forging processes, J. Mater. Res. Technol., 2016, vol. 5, no. 1, pp. 5–12.

Kolodnits’kyi, V.M. and Bagirov, O.E., On the structure formation of diamond-containing composites used in drilling and stone-working tools (A review), J. Superhard Mater., 2017, vol. 39, no. 1, pp. 1–17.

Mechnyk, V.A., Regularities of structure formation in diamond-Fe-Cu-Ni-Sn-CrB2 systems, Mater. Sci., 2013, vol. 49, no. 1, pp. 93–101.

Nitkiewicz, Z. and Swierzy, M., Tin influence on diamond-metal matrix hot pressed tools for stone cutting, J. Mater. Proc. Tech., 2006, vol. 175, nos. 1–3, pp. 306–315.

Mechnik, V.A., Production of diamond-(Fe-Cu-Ni-Sn) composites with high wear resistance, Powder Metall. Met. Ceram., 2014, vol. 52, nos. 9–10, pp. 577–587.

Mechnik, V.A., Effect of hot recompaction parameters on the structure and properties of diamond-(Fe-Cu-Ni-Sn-CrB2) composites, Powder Metall. Met. Ceram., 2014, vol. 52, nos. 11–12, pp. 709–721.

Sidorenko, D.A., Zaitsev, A.A., Kirichenko, A.N., Levashov, E. A., Kurbatkina, V.V., Loginov, P.A., Rupasov, S.I., and Andreev, V.A., Interaction of diamond grains with nanosized alloying agents in metal-matrix composites as studied by Raman spectroscopy, Diamond Relat. Mater., 2013, vol. 38, pp. 59–62.

Zaitsev, A.A., Sidorenko, D.A., Levashov, E.A., Kurbatkina, V.V., Andreev, V.A., Rupasov, S.I., and Sevast’yanov, P.V., Diamond tools in metal bonds dispersion-strengthened with nanosized particles for cutting highly reinforced concrete, J. Superhard Mater., 2010, vol. 32, no. 6, pp. 423–431.

Zhang, S., Bui, X.L., Jiang, J., and Li, X., Microstructure and tribological properties of magnetron sputtered nc-TiC/a-C nanocomposites, Surf. Coat. Tech., 2005, vol. 198, pp. 206–211.

Tay, B.K., Cheng, Y.H., Ding, X.Z., Lau, S.P., Shi, X., You, G.F., and Sheeja, D., Hard carbon nanocomposite films with low stress, Diamond Relat. Mater., 2001, vol. 10, pp. 1082–1087.

Musil, J., Tribological and mechanical properties of nanocrystalline-TiC/a-C nanocomposite thin films, J. Vac. Sci. Technol. A., 2010, vol. 28, no. 2, pp. 244–249.

Teer, D.G., New solid lubricant coatings, Wear, 2001, vol. 251, pp. 1068–1074.

Gleiter, H., Nanostructured materials: basic concepts and microstructure, Acta Mater., 2000, vol. 48, no. 1, pp. 1–29.

Gleiter, H., Materials with ultrafine microstructures: Retrospectives and perspectives, Nanostruct. Mater., 1992, vol. 1, no 1. pp. 1–19.

Gusev A.I. Nanomaterialy, nanostructury, nanotochnologii (Nanomaterials, Nanostructures, and Nanotechnologies), Moscow: Fizmatlit, 2009.

Pogrebnyak, A.D., Sobol’, O.V., Beresnev, V.M., Turbin, P.V., Dub, S.N., Kirik, G.V., and Dmitrenko, A.E., Features of the structural state and mechanical properties of ZrN and Zr(Ti)-Si-N coatings obtained by ion-plasma deposition technique, Tech. Phys. Lett., 2009, vol. 35, no. 10, art. 925.

Zhiwei, W.U., Zhang, J., Yi, C., and Liang, M., Effect of rare earth addition on microstrucural, mechanical and electrical characteristics of Cu-6%Fe microcomposites, J. Rare Earths, 2009, vol. 27, no. 1, pp. 87–91.

He, L. and Ma, E., Processing and microhardness of bulk Cu-Fe, Nanostruct. Mater., 1996, vol. 7, no. 3, pp. 327–339.

Akhmadeev, N.A., Kobelev, N.P., Mulyukov, R.R., Soifer, Ya.M., and Valiev, R.Z., The effect of heat treatment on the elastic and dissipative properties of copper with the submicrocrystalline structure, Acta Metall. Mater., 1993, vol. 41, no. 4, pp. 1041–1046.

Gusev, A.I., Effects of the nanocrystalline state in solids, Phys. Usp., 1998, vol. 41, pp. 49–76.

Robertson, A., Erb, U., and Palumbo, G., Practical applications for electrodeposited nanocrystalline materialsn, Nanostr. Mater., 1999, vol. 12, nos. 5–8, pp. 1035–1040.

Mechnik, V.A., Bondarenko, N.A., Dub, S.N., Kolodnitskyi, V.M., Nesterenko, Yu.V., Kuzin, N.O., Zakiev, I.M., and Gevorkyan, E.S., A study of microstructure of Fe-Cu-Ni-Sn and Fe-Cu-Ni-Sn-VN metal matrix for diamond containing composites, Mater. Charact., 2018, vol. 146, pp. 209–216.

Mechnik, V.A., Bondarenko, N.A., Kolodnitskyi, V.M., Zakiev, V.I., Zakiev, I.M., Storchak, M., Dub, S.N., and Kuzin, N.O., Physico-mechanical and tribological properties of Fe-Cu-Ni-Sn and Fe-Cu-Ni-Sn-VN nanocomposites obtained by powder metallurgy methods. Tribol. Ind., 2019, vol. 41, no. 2, pp. 188–198.

Rabinowicz, E., Friction and wear of materials, New York: Wiley, 1995.

Leyland, A. and Matthews, A., On the significance of the H/E ratio in wear control: a nanocomposite coating approach to optimised tribological behaviour, Wear, 2000, vol. 246, nos. 1–2, pp. 1–11.

Novikov, N.V., Voronkin, M.A., Dub, S.N., Lupich, I.N., Malogolovets, V.G., Maslyuk, B.A., and Podzyarey, G.A., Transition from polimer-like to diamond-like a-C:H films: Structure and mechanical properties, Diamond Relat. Mater., 1997, vol. 6, nos. 5–7, pp. 574–578.

Soldan, J. and Musil, J., Structure and mechanical properties of DC magnetron sputtered TiC/Cu films, Vacuum, 2006, vol. 81, no. 4, pp. 531–538.

Aleksandrov, V.A., Akekseenko, N.A., and Mechnik, V.A., Study of force and energy parameters in cutting granite with diamond disc saws, Sov. J. Superhard Mater., 1984, vol. 6, no. 6, pp. 46–52.

Aleksandrov, V.A., Zhukovsky, A.N., and Mechnik, V.A., Temperature field and wear of inhomogeneous diamond wheel at convective heat exchange, Trenie Iznos, 1994, vol. 15, no. 1, pp. 27–35.

Aleksandrov, V.A., Zhukovskij, A.N., and Mechnik, V.A., Temperature field and wear of heterogeneous diamond wheel under conditions of convectional heat transfer. Part 2, Trenie Iznos, 1994, vol. 15, no. 2, pp. 196–201.

Dutka, V.A., Kolodnitskij, V.M., Zabolotnyj, S.D., Sveshnikov, I.A., and Lukash, V.A., Simulation of the temperature level in rock destruction elements of drilling bits, Sverkhtverd. Mater., 2004, no. 2, pp. 66–73.

Dutka, V. A., Kolodnitskij, V. M., Mel’nichuk, O. V., and Zabolotnyj, S.D., Mathematical model for thermal processes occurring in the interaction between rock destruction elements of drilling bits and rock mass, Sverkhtverd. Mater., 2005, no. 1, pp. 67–77.

Zhukovskij, A.N., Majstrenko, A.L., Mechnik, V.A., and Bondarenko, N.A., The stress-strain state of the bonding around the diamond grain exposed to normal and tangent loading components. Part 1. Model, Trenie Iznos, 2002, vol. 23, no. 2, pp. 146–153.

Zhukovskij, A.N., Majstrenko, A.L., Mechnik, V.A., and Bondarenko, N.A., Stress-strain state of the matrix around the diamond grain exposed to the normal and tangent loading components. Part 2. Analysis, Trenie Iznos, 2002, vol. 23, no. 4, pp. 393–396.

Sveshnikov, I.A and Kolodnitsky, V.N., Optimization of the hard alloy cutter arrangement in the drilling bit body, Sverkhtverd. Mater., 2006, vol. 28, no. 4, pp. 70–75.

Lyakishev, N.P. and Alymov, M.I., Nanomaterials for construction purposes, Ross. Nanotekhnol., 2006, vol. 1, nos. 1–2, pp. 71–81.

Khasanov, O.L., Sokolov, V.M., Dvilis, E.S., and Pokholkov, Yu.L., Ul’trazvukovaya technologiya izgotovleniya konstruktsionnoi i funktsional’noi nanokeramiki (Ultrasound technology of structure and functional nanoceramics production), Perspectivnye Mater., 2002, no. 1, pp. 76–83.

Bykov, Y., Gusev, S., Eremeev, A., Holoptsev, V., Malygin, N., Pivarunas, S., Sorokin, A., and Shurov, A., Sintering of nanophase oxide ceramics by using millimeter-wave radiation, Nanostr. Mater., 1995, vol. 6, nos. 5–8, pp. 855–858.

Kovneristy, Yu.K., Ob”emno-amortiziruyushchiesya metallicheskie splavy (Bulk Amorphizing Metal Alloys) Moscow: Nauka, 1999.

Pang, S.J., Zhang, T., Asami, K., and Inoue, A., Synthesis of Fe-Cr-Mo-C-B-P bulk metallic glasses with high corrosion resistance, Acta Mater., 2002, vol. 50, no. 3, pp. 489–497.

Saito, Y., Utsunomiya, H., Tsuji, N., and Sakai, T., Novel ultra-high straining process for bulk materials-development of the accumulative roll-bonding (ARB) process, Acta Mater., 1999, vol. 47, no. 2, pp. 579–583.

Korznikov, A.V., Ivanisenko, Yu.V., Laptionok, D.V., and Safarov, I.M., Influence of severe plastic deformation on structure and phase composition of carbon steel, Nanostr. Mater., 1994, vol. 4, no. 2, pp. 159–167.

Lyakishev N.P., Alymov M.I., and Dobatkin S.V., Ob”emnye nanomaterialy konstrukzionnogo naznzcheniya (Bulk nanomaterials for construction purposes), Metally, 2003, no. 3, pp. 3–16.

Kodash, V.Y. and Gevorkian, E.S., USA Patent No. 6617271 B1, Publ. 09.09.2003.

Kraus, W. and Nolze, G. POWDER CELL-A program for the representation and manipulation of crystal structures and calculation of the resulting X-ray powder patterns, J. Appl. Cryst., 1996, vol. 29, pp. 301–303.

Selected Powder Diffraction Data for Education and Training: Search Manual and Data Cards. Published by the International Centre for Diffraction Data, USA, 1988.

Oliver, W.C. and Pharr, G.M., An improved for determining hardness and elastic modulus using load and displacement sensing indentation experiments, J. Mater. Res., 1992, vol. 7, no. 6, pp. 1564–1583.

Zakiev, V., Markovsky, A., Aznakayev, E., Zakiev, I., and Gursky, E., Micro-mechanical properties of bio-materials, Proc. SPIE 5959, Medical Imaging, 595916 (23 September 2005), Event: Congress on Optics and Optoelectronics, 2005, Warsaw, Poland, doi:https://doi.org/10.1117/12.628396.

Firstov, S.A., Gorban, V.F., Krapivka, N.A., Pechkovskii, É.P., Danilenko, N.I., and Karpets, M.V., Mechanical properties of multicomponent titanium alloy, Strength Mater., 2010, vol. 42, no. 5, pp. 622–630.

Hao, Y.L., Li, S.J., Sun, S.Y., Zheng, C.Y., and Vang, R., Elactic deformation behaviour of Ti-24Nb-4Zn-7.9Sn for biomedical application, Acta Biomaterialia, 2007, vol. 3, no. 2, pp. 277–286.

Hassani, S., Bielawski, M., Beres, W., Martinu, L., Balazinski, M., and Klemberg-Sapieha, J.E., Predictive tools for the design of erosion resistant coatings, Surf. Coat. Technol., 2008, vol. 203, nos. 3–4, pp. 204–210.

Bousser, E., Benkahoul, M., Martinu, L., and Klemberg-Sapieha, J.E., Effect of microstructure on the erosion resistance of Cr-Si-N coatings, Surf. Coat. Technol., 2008, vol. 203, nos. 5–7, pp. 776–778.

Funding

The work was performed in the framework of state budget research topics in accordance with the coordination plans of the Ministry of Education and Science of Ukraine (state registration number of the project No. 0117U000391).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Russian Text © The Author(s), 2019, published in Sverkhtverdye Materially, 2019, Vol. 41, No. 6, pp. 26–43.

About this article

Cite this article

Mechnik, V.A., Bondarenko, N.A., Kolodnitskyi, V.M. et al. Formation of Fe-Cu-Ni-Sn-VN Nanocrystalline Matrix by Vacuum Hot Pressing for Diamond-Containing Composite. Mechanical and Tribological Properties. J. Superhard Mater. 41, 388–401 (2019). https://doi.org/10.3103/S1063457619060030

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S1063457619060030