Abstract

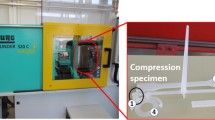

A number of results obtained during the numerical finite element analysis of a procedure to test the ring specimens of polymer materials under internal pressure are discussed. The internal pressure is produced by the compression of an inset made of an incompressible material in the cavity of the specimen under test. The analysis is performed for the ring polyarylate specimens. The stress distributions in the specimen are obtained under constant load. It is shown that the stress distribution in the cross section of the specimen is not uniform for this type of loading. The effect of the elastic modulus and Poisson’s ratio of the loading inset on the tensile stresses in the specimen is studied. It is also shown that it is possible to use the maximum stress value or the stress intensity to estimate the long-term strength of polymer rings. The numerical results are used to estimate the durability of polyarylate sealing rings obtained by pressure casting at various temperature values. The experimental dependencies of time before fracture are given as functions of the maximum stress for the polymer specimens manufactured at the temperatures equal to 310 and 350° C. A new exponential dependence is proposed to approximate the experimental curves.

Similar content being viewed by others

References

Yu. N. Rabotnov, Creep Problems in Structural Members (North-Holland Pub. Co., Amsterdam, 1969).

N. A. Makhutov, Strength and Safety. Basic and Applied Research (Nauka, Novosibirsk, 2008) fin Russian].

W. F. Busse, E. T. Lessig, D. L. Loughborough, and L. Larrick, “Fatigue of Fabrics,” J. Appl. Phvs. 13 (11), 715–723.

S. N. Zhurkov, “Kinetic Concept of the Strength of Solids,” Int. J. Fract. Mech. 26 (4), 295–307 (1984).

S. N. Zhurkov and B. I. Narzulavev, “The Time Dependence of the Strength of Solids,” Zhurn. Teor. Fiz. 23 (10), 1677–1680 (1953).

S. N. Zhurkov and S. A. Abasov, “The Temperature and Time Dependence of the Strength of Polvmer Fibers,” Vysokomolek. Soedinen. 3 (3), 441–449 (1961).

S. N. Zhurkov and V. E. Korsukov, “Atomic Mechanism of Polymer Fracture under Load,” Fiz. Tverdogo Tela 15 (7), 2071–2078 (1973).

V. R. Regel’, A. I. Slutsker, and E. E. Tomashevskii, Kinetic Nature of Strength (Nauka, Moscow, 1974) [in Russian].

ISO 20753:2008(E). Plastics — Test specimens, https://www.sis.se/api/document/preview/909653/. Cited March 25, 2019.

R. P. Brown, “Durability of Polymers — Material Property Data,” Polym. Test. 12 (5), 423–428 (1993).

J. Moon, H. Bae, J. Song, and S. Choi, “Algorithmic Methods of Reference-Line Construction for Estimating Long-Term Strength of Plastic Pipe System,” Polym. Test. 56, 58–64 (2016).

Yu. M. Tarnopol’skii and T. Ya. Kintsis, Static Methods of Testing Reinforced Plastics (Khimiya, Moscow, 1975) [in Russian].

V. V. Partsevskii, “On the Tension of an Anisotropic Ring by Rigid Half-Disks,” Mekh. Polim., No. 6, 1113–1116 (1970).

B. A. Avdeev, Technique for Determining the Mechanical Properties of Materials (Metallurgiya, Moscow, 1949) [in Russian].

R. E. Brivmanis and G. G. Portnov, “Strength of Glass-Reinforced Plastic Rings Loaded with Internal Pressure,” Polym. Mech. 4 (1), 92–94 (1968).

G. B. Sinclair, “Stress Singularities in Classic Elasticity. I: Removal, Interpretation, and Analysis,” Appl. Mech. Revs. 57 (4), 251–297 (2004).

G. Wypych, “PAR Polyarylate,” in Handbook of Polymers (ChemTec Publ., Toronto, 2016), pp. 280–282.

B. D. Dean, M. Matzner, and J. M. Tibbitt, “Polyarylates,” Comprehens. Polym. Sci. 5, 317–329 (1989).

Solving Contact Problems in ANSYS 6.1 (CADFEM, Moscow, 2003) [in Russian].

ANSYS Textbook (Perm Gos. Tekh. Univ., Perm, 2008) [in Russian].

I. I. Akimova and Yu. P. Zezin, “Fracture Resistance and Long-Term Strength of Dispersion-Hardened Composites,” Mekh. Compos. Mater. 5, 869–877 (1989).

M. S. Song, G. X. Hu, L. J. Hu, “Prediction of Long-Term Mechanical Behaviour and Lifetime of Polymeric Materials,” Polym. Test. 17 (5), 311–332 (1998).

R. P. Brown, “Durability of Polymers-Material Property Data,” Polym. Test. 12 (5), 423–428 (1993).

A. P. Arshakuni and S. A. Shesterikov, “Long-Term Strength Prediction for Heat-Proof Metallic Materials,” Izv. Akad. Nauk, Mekh. Tverd. Tela, No. 3, 126–141 (1994).

A. L. Arshakuni, “Prediction of Long-Time Strength of Metals,” Izv. Ross. Akad. Nauk, Mekh. Tverd. Tela, No. 6, 126–135 (1997).

Author information

Authors and Affiliations

Corresponding author

Additional information

Russian Text © Yu.P. Zezin, P.V. Tishin, 2019, published in Vestnik Moskovskogo Universiteta, Matematika. Mekhanika, 2019, Vol. 74, No. 2, pp. 22–28.

About this article

Cite this article

Zezin, Y.P., Tishin, P.V. Procedure to Experimentally Estimate the Long-Term Strength of Polymer Materials Using the Test Results for Ring Specimens. Moscow Univ. Mech. Bull. 74, 29–35 (2019). https://doi.org/10.3103/S0027133019020018

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.3103/S0027133019020018