Abstract

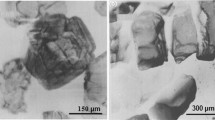

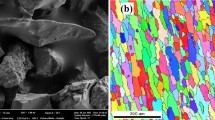

The scope of the present study is focused on high-entropy alloy (HEA), a new type of alloy system-reinforced aluminium metal matrix composite (AMMC) development. The novel metal–metal composite is fabricated through powder metallurgy by reinforcing prepared AlCoCrCuFe HEA particles with aluminium. Headed for identifying the effect of HEA on aluminium, weight percentage of HEA is varied from 0 to 15% with an equal interval of 3%. By using X-ray diffractometer, phase constituents of HEA and Al base material are analysed besides the fact that the scanning electron microscope is utilized for morphology analysis of HEA particles and AMMC. Density of the aluminium increases gradually with the increase in HEA content due to higher density of reinforcements, and maximum micro-hardness of 71.3 HV is attained for 15% HEA reinforcement addition which is 37.6 HV for unreinforced aluminium. Among the various predictive methodologies, the density and hardness of Al–AlCoCrCuFe metal–metal composite are found close to the values predicted by the Reuss and Voigt model, respectively. Decrease in wear rate was found for aluminium MMC with the increase in HEA reinforcement addition.

Similar content being viewed by others

References

K.P. Kumar, M.G. Krishna, J.B. Rao, N. Bhargava, Fabrication and characterization of 2024 aluminium–high entropy alloy composites. J. Alloys Compd. 640, 421–427 (2015)

B. Stojanović, M. Babić, S. Veličković, J. Blagojević, Tribological behavior of aluminum hybrid composites studied by application of factorial techniques. Tribol. Trans. 59, 522–529 (2016)

S. Suresh, N.S.V. Moorthi, S.C. Vettivel, N. Selvakumar, G.R. Jinu, Effect of graphite addition on mechanical behavior of Al6061/TiB2 hybrid composite using acoustic emission. Mater. Sci. Eng. A 612, 16–27 (2014)

S. Scudino, G. Liu, K.G. Prashanth, B. Bartusch, K.B. Surreddi, B.S. Murty, J. Eckert, Mechanical properties of Al-based metal matrix composites reinforced with Zr-based glassy particles produced by powder metallurgy. Acta Mater. 57, 2029–2039 (2009)

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler, E.P. George, Temperature dependencies of the elastic moduli and thermal expansion coefficient of an equiatomic, single-phase CoCrFeMnNi high-entropy alloy. J. Alloys Compd. 623, 348–353 (2015)

G.M. Karthik, S. Panikar, G.D.J. Ram, R.S. Kottada, Additive manufacturing of an aluminum matrix composite reinforced with nanocrystalline high-entropy alloy particles. Mater. Sci. Eng. A 679, 193–203 (2017)

Y.F. Ye, Q. Wang, J. Lu, C.T. Liu, Y. Yang, High-entropy alloy: challenges and prospects. Mater. Today 19, 349–362 (2016)

W. Ji, Z. Fu, W. Wang, H. Wang, J. Zhang, Y. Wang, F. Zhang, Mechanical alloying synthesis and spark plasma sintering consolidation of CoCrFeNiAl high-entropy alloy. J. Alloys Compd. 589, 61–66 (2014)

J. Chen, P. Niu, T. Wei, L. Hao, Y. Liu, X. Wang, Y. Peng, Fabrication and mechanical properties of AlCoNiCrFe high-entropy alloy particle reinforced Cu matrix composites. J. Alloys Compd. 649, 630–634 (2015)

A. Bokulich, Maxwell, Helmholtz, and the unreasonable effectiveness of the method of physical analogy. Stud. Hist. Philos. Sci. Part A 50, 28–37 (2015)

H.J. Edrees, A.C. Smith, A. Hendry, A rule-of-mixtures model for sintering of particle-reinforced ceramic-matrix composites. J. Eur. Ceram. Soc. 18, 275–278 (1998)

I. Jäger, P. Fratzl, Mineralized collagen fibrils: a mechanical model with a staggered arrangement of mineral particles. Biophys. J. 79, 1737–1746 (2000)

H.S. Kim, On the rule of mixtures for the hardness of particle reinforced composites. Mater. Sci. Eng., A 289, 30–33 (2000)

G.R. Liu, A step-by-step method of rule-of-mixture of fiber-and particle-reinforced composite materials. Compos. Struct. 40, 313–322 (1997)

Y. Prawoto, J.R.P. Djuansjah, N.B. Shaffiar, Re-visiting the ‘rule of mixture’used in materials with multiple constituting phases: a technical note on morphological considerations in austenite case study. Comput. Mater. Sci. 65, 528–535 (2012)

F. Assous, P. Degond, E. Heintze, P.-A. Raviart, J. Segré, On a finite-element method for solving the three-dimensional Maxwell equations. J. Comput. Phys. 109, 222–237 (1993)

F. Hermeline, A finite volume method for solving Maxwell equations in inhomogeneous media on arbitrary meshes. C. R. Math. 339, 893–898 (2004)

V.I. Kushch, I. Sevostianov, Maxwell homogenization scheme as a rigorous method of micromechanics: application to effective conductivity of a composite with spheroidal particles. Int. J. Eng. Sci. 98, 36–50 (2016)

F. Assous, P. Degond, J. Segré, Numerical approximation of the Maxwell equations in inhomogeneous media by aP1Conforming finite element method. J. Comput. Phys. 128, 363–380 (1996)

V.A. Rukavishnikov, A.O. Mosolapov, New numerical method for solving time-harmonic Maxwell equations with strong singularity. J. Comput. Phys. 231, 2438–2448 (2012)

A. Yefet, E. Turkel, Fourth order compact implicit method for the Maxwell equations with discontinuous coefficients. Appl. Numer. Math. 33, 125–134 (2000)

S. Praveen, B.S. Murty, R.S. Kottada, Alloying behavior in multi-component AlCoCrCuFe and NiCoCrCuFe high entropy alloys. Mater. Sci. Eng. A 534, 83–89 (2012)

K.S. Prakash, R.S. Moorthy, P.M. Gopal, V. Kavimani, Effect of reinforcement, compact pressure and hard ceramic coating on aluminium rock dust composite performance. Int. J. Refract. Met. Hard Mater. 54, 223–229 (2016). https://doi.org/10.1016/j.ijrmhm.2015.07.037

K.S. Prakash, P. Balasundar, S. Nagaraja, P.M. Gopal, Mechanical and wear behaviour of Mg–SiC–Gr hybrid composites. J. Magnes. Alloy. 4, 197–206 (2016). https://doi.org/10.1016/j.jma.2016.08.001

P.M. Gopal, K.S. Prakash, S. Nagaraja, N.K. Aravinth, Effect of weight fraction and particle size of CRT glass on the tribological behaviour of Mg–CRT–BN hybrid composites. Tribol. Int. 116, 338–350 (2017)

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Soorya Prakash, K., Gopal, P.M., Purusothaman, M. et al. Fabrication and Characterization of Metal-High Entropy Alloy Composites. Inter Metalcast 14, 547–555 (2020). https://doi.org/10.1007/s40962-019-00383-4

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40962-019-00383-4