Abstract

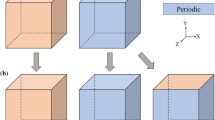

A novel approach has been developed to estimate fatigue life at the specimen/component level from the simulation of relatively small Representative Volume Elements (RVE) of the polycrystalline microstructure. This technique estimates the statistical distribution of fatigue lives under general multiaxial loading conditions accounting for both microstructure and specimen size. The model relies on computational homogeneization where the crystal behavior follows a crystal plasticity model and simulations are performed using a FFT based solver. The simulation of the cyclic response of a set of different RVEs provides the statistical distribution of Fatigue Indicator Parameters for that RVE size, which can be accurately represented by an extreme value distribution as the Gumbel distribution. This distribution is upscaled to the actual size of the specimen or component of interest using a weakest link approach and is finally transformed into a distribution of fatigue lives using a simple fatigue-life expression fitted with experiments. The framework proposed estimates fatigue lives of specimens with millions of grains from the results obtained with RVEs containing only hundreds of grains and is able to reproduce the specimen size effect on fatigue life. The approach is first numerically validated and then used to predict the statistical distribution of fatigue life of a polycrystalline Ni-based superalloy showing very accurate results.

Similar content being viewed by others

References

Asaro R, Needleman A (1985) Overview no. 42 texture development and strain hardening in rate dependent polycrystals. Acta Metallurgica 33(6):923–953

Carpinteri A, Spagnoli A, Vantadori S (2009) Size effect in s-n curves: a fractal approach to finite-life fatigue strength. Int J Fatigue 31(5):927–933

Castelluccio GM, McDowell DL (2014) Mesoscale modeling of microstructurally small fatigue cracks in metallic polycrystals. Mater Sci Eng A 598:34–55

Chen B, Jiang J, Dunne FP (2018) Is stored energy density the primary meso-scale mechanistic driver for fatigue crack nucleation? Int J Plasticity 101:213–229

Cruzado A, Gan B, Jimenez M, Barba D, Ostolaza K, Linaza A, Molina-Aldareguia J, Llorca J, Segurado J (2015) Multiscale modeling of the mechanical behavior of in718 superalloy based on micropillar compression and computational homogenization. Acta Materialia 98:242–253

Cruzado A, LLorca J, Segurado J (2017) Modeling cyclic deformation of inconel 718 superalloy by means of crystal plasticity and computational homogenization. Int J Solids Struct 122:148–161

Cruzado A, Lucarini S, LLorca J, Segurado J (2018a) Crystal plasticity simulation of the effect of grain size on the fatigue behavior of polycrystalline inconel 718. Int J Fatigue 113:236–245

Cruzado A, Lucarini S, LLorca J, Segurado J (2018b) Microstructure-based fatigue life model of metallic alloys with bilinear coffin-manson behavior. Int J Fatigue 107(Supplement C):40–48

de Geus T, Vondřejc J, Zeman J, Peerlings R, Geers M (2017) Finite strain fft-based non-linear solvers made simple. Comput Methods Appl Mech Eng 318:412–430

Dunne F (2014) Fatigue crack nucleation: mechanistic modelling across the length scales. Curr Opin Solid State Mater Sci 18:170–179

Eisenlohr P, Diehl M, Lebensohn R, Roters F (2013) A spectral method solution to crystal elasto-viscoplasticity at finite strains. Int J Plasticity 46:37–53

Freudenthal A, Gumbel E (1956) Physical and statistical aspects of fatigue. In: Advances in applied mechanics. pp 117–158

Furuya Y (2008) Specimen size effects on gigacycle fatigue properties of high-strength steel under ultrasonic fatigue testing. Scripta Materialia 58(11):1014–1017

Geers M, Kouznetsova V, Brekelmans W (2010) Multi-scale computational homogenization: trends and challenges. J Comput Appl Math 234(7):2175–2182

Griffith AA, Taylor GI (1921) Vi. the phenomena of rupture and flow in solids. Phil Trans R Soc London A 221(582–593):163–198

Gumbel E (1958) Statistics of extremes. Columbia University Press, New York

Herrera-Solaz V, LLorca J, Dogan E, Karaman I, Segurado J (2014) An inverse optimization strategy to determine single crystal mechanical behavior from polycrystal tests: Application to az31 mg alloy. Int J Plasticity 57:1–15

Hill R (1963) Elastic properties of reinforced solids: some theoretical principles. J Mech Phys Solids 11(5):357–372

Lucarini S, Segurado J (2019a) An algorithm for stress and mixed control in galerkin-based fft homogenization. Int J Numer Methods Eng 119(8):797–805

Lucarini S, Segurado J (2019b) Dbfft: A displacement based fft approach for non-linear homogenization of the mechanical behavior. Int J Eng Sci 144:103131

Lucarini S, Segurado J (2019c) On the accuracy of spectral solvers for micromechanics based fatigue modeling. Comput Mech 63(2):365–382

Manonukul A, Dunne FPE (2004) High- and low-cycle fatigue crack initiation using polycrystal plasticity. Proc R Soc London A 460:1881–1903

Martin G, Ochoa N, Sa K, Hervé-Luanco E, Cailletaud G (2014) A multiscale model for the elastoviscoplastic behavior of directionally solidified alloys: application to FE structural computations. Int J Solids Struct 51(5):1175–1187

McDowell D, Dunne F (2010) Microstructure-sensitive computational modeling of fatigue crack formation. Int J Fatigue 32(9):1521–1542 emerging Frontiers in Fatigue

Ohno N, Wang JD (1993) Kinematic hardening rules with critical state of dynamic recovery. Part II: application to experiments of ratcheting behavior. Int J Plasticity 9:391–403

Pineau A, McDowell DL, Busso EP, Antolovich SD (2016) Failure of metals. II: Fatigue. Acta Materialia 107:484–507

Przybyla CP, McDowell DL (2010) Microstructure-sensitive extreme value probabilities for high cycle fatigue of ni-base superalloy in100. Int J Plasticity 26(3):372–394

Przybyla CP, Musinski WD, Castelluccio GM, McDowell DL (2013) Microstructure-sensitive HCF and VHCF simulations. Int J Fatigue 57:9–27

Rovinelli A, Lebensohn RA, Sangid MD (2015) Influence of microstructure variability on short crack behavior through postulated micromechanical short crack driving force metrics. Eng Fract Mech 138:265–288

Segurado J, Lebensohn RA, LLorca J (2018) Chapter one—computational homogenization of polycrystals. In: Hussein MI (ed) Advances in crystals and elastic metamaterials, advances in applied mechanics, vol 51. Elsevier, New York, pp 1–114

Shenoy M, Tjiptowidjojo Y, McDowell DL (2008) Microstructure-sensitive modeling of polycrystalline IN 100. Int J Plasticity 24:1694–1730

Sun C, Song Q (2018) A method for predicting the effects of specimen geometry and loading condition on fatigue strength. Metals. 8:811

Sun C, Zhang X, Liu X, Hong Y (2016) Effects of specimen size on fatigue life of metallic materials in high-cycle and very-high-cycle fatigue regimes. Fatigue Fract Eng Mater Struct 39(6):770–779

Sweeney C, McHugh P, McGarry J, Leen S (2012) Micromechanical methodology for fatigue in cardiovascular stents. Int J Fatigue 44:202–216

Sweeney CA, O’Brien B, McHugh PE, Leen SB (2014) Experimental characterisation for micromechanical modelling of CoCr stent fatigue. Biomaterials 35:36–48

Sweeney CA, O’Brien B, Dunne FPE, McHugh PE, Leen SB (2015) Micro-scale testing and micromechanical modelling for high cycle fatigue of CoCr stent material. J Mech Behav Biomed Mater 46:244–260

Tome C, Canova G, Kocks U, Christodoulou N, Jonas J (1984) The relation between macroscopic and microscopic strain hardening in f.c.c. polycrystals. Acta Metallurgica 32(10):1637–1653

Vondřejc J, Zeman J, Marek I (2014) An fft-based galerkin method for homogenization of periodic media. Comput Math Appl 68(3):156–173

Wan VVC, MacLachlan DW, Dunne FPE (2014) A stored energy criterion for fatigue crack nucleation in polycrystals. Int J Fatigue 68:90–102

Weibull W (1939) A statistical theory of the strength of materials. Swedish Inst Eng Res 1(51):1–45

Willot F, Abdallah B, Pellegrini YP (2014) Fourier-based schemes with modified green operator for computing the electrical response of heterogeneous media with accurate local fields. Int J Num Methods Eng 98(7):518–533

Yeratapally SR, Glavicic MG, Hardy M, Sangid MD (2016) Microstructure based fatigue life prediction framework for polycrystalline nickel-base superalloys with emphasis on the role played by twin boundaries in crack initiation. Acta Materialia 107:152–167

Zeman J, de Geus TWJ, Peerlings RHJ, Geers MGD (2017) A finite element perspective on nonlinear fft-based micromechanical simulations. Int J Num Methods Eng 111(10):903–926

Acknowledgements

This investigation was supported by ITP Aero, the Spanish Ministry of Economy and Competitiveness through the project DPI2015-67667-C3-2-R and the Spanish Science, Innovation and Universities through the project NVIDIA (RTC-2017-6150-4).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Lucarini, S., Segurado, J. An upscaling approach for micromechanics based fatigue: from RVEs to specimens and component life prediction. Int J Fract 223, 93–108 (2020). https://doi.org/10.1007/s10704-019-00406-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10704-019-00406-5