Abstract

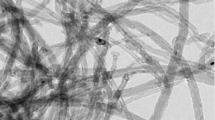

Cu and Al2O3 nanopowders were synthesized from 3CuO and 2Al by high energy ball milling. The powder sizes of Cu and Al2O3 were 14 nm and 133 nm, respectively. A dense nanocrystalline 3Cu-Al2O3 composite was consolidated by a high frequency induction heated sintering method within 2 minutes from the mechanically synthesized powders. The average hardness and fracture toughness values of the nanostuctured 3Cu-Al2O3 composite were 520 kg/mm2 and 5 Mpa·m1/2, respectively.

Similar content being viewed by others

References

L. Ceschini, G. Minak, and A. Morri, Compos. Sci. Technol. 66, 333 (2006).

S. C. Tjong and Z. Y. Ma, Mater. Sci. Eng. 29, 49 (2000).

D. J. Lloyd, Int. Mater. Rev. 39, 1 (1994).

J. M. Torralba and F. Velasco, J. Mater. Process. Technol. 133, 203 (2003).

R. Fan, B. Liu, J. Zhang, J. Bi, and Y. Yin, Mater. Chem. Phys. 91, 40 (2005).

S. Paris, E. Gaffet, F. Bernard, and Z.A. Munir, Scripta Mater. 50, 691 (2004).

H. Gleiter, Nanostruct. Mater. 6, 3 (1995).

J. R. Yoon, D. J. Choi, K. H. Lee, J. Y. Lee, and Y. H. Kim, Electron. Mater. Lett. 4, 167 (2008)

J. Karch, R. Birringer, and H. Gleiter, Nature. 330, 556 (1987).

A. M. George, J. Iniguez, and L. Bellaiche, Nature. 413, 54 (2001).

D. Hreniak and W. Strek, J. Alloy. Compd. 341, 183 (2002).

C. Xu, J. Tamaki, N. Miura, and N. Yamazoe, Sensor. Actuat. B: Chem. 3, 147 (1991).

D. G. Lamas, A. Caneiro, D. Niebieskikwiat, R. D. Sanchez, D. Garcia, and B. Alascio, J. Magn. Magn. Mater. 241, 207 (2002).

C. Nahm, C. Kim, Y. Park, B. Lee, and B. Park, Electron. Mater. Lett. 4, 5 (2008).

E. S. Ahn, N. J. Gleason, A. Nakahira, and J. Y. Ying, Nano Lett. 1, 149 (2001).

Z. Fang, and J.W. Eason, Int. J. Refract. Met. Hard Mater. 13, 297 (1995).

A. I. Y. Tok, L. H. Luo, and F. Y. C. Boey, Mater. Sci. Eng. A. 383, 229 (2004).

M. Sommer, W. D. Schubert, E. Zobetz, and P. Warbichler, Int. J. Refract. Met. Hard Mater. 20, 41 (2002).

H. C. Kim, I. J. Shon, I. K. Jeong, I. Y. Ko, J. K. Yoon, and J. M. Doh, Met. Mater. Int. 13, 39 (2007).

C. Suryanarayana, and M. Grant Norton, X-ray Diffraction A Practical Approach, p. 213, Plenum Press, New York (1998).

G. R. Anstis, P. Chantikul, B. R. Lawn, and D. B. Marshall, J. Am. Ceram. Soc. 64, 533 (1981).

M. N. Rahaman, A. Yao, B. S. Bal, J. P. Garino, and M. D. Ries, J. Am. Ceram. Soc. 90, 1965 (2007).

http://en.wikipedia.org/wiki/Elastic properties of the elements (data page).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shon, IJ., Lee, JY., Nam, KS. et al. Mechanical synthesis and rapid consolidation of a nanocrystalline Cu-Al2O3 composite by high frequency induction heated sintering. Electron. Mater. Lett. 5, 77–81 (2009). https://doi.org/10.3365/eml.2009.06.077

Issue Date:

DOI: https://doi.org/10.3365/eml.2009.06.077