Abstract

A concise, two-dimensional discrete heat transfer model is presented, which considers the thermal resistance effects of cracks. The discrete heat transfer model discretizes the continuum into individual triangular elements, and the adjacent triangular elements transfer heat through corresponding joint elements. Then, the principle of selecting the heat exchange coefficient of the joint element is determined through a parameter sensitivity analysis. Moreover, the 2D discrete heat transfer model is combined with the finite discrete element method to build a thermomechanical coupled model for simulating brittle material thermal cracking. The thermal stress and thermal shock problems are studied by using the thermomechanical coupled model, and the numerical results are compared with either the analytical solution or experimental results to validate the 2D discrete heat transfer model and thermomechanical coupled model. The discrete heat transfer model and thermomechanical coupled model provide a powerful tool for solving heat transfer problems in discontinuous media as well as the thermal cracking problem in brittle materials.

Similar content being viewed by others

Abbreviations

- \(q_{i}\) :

-

Heat flow rate along the \(i\) direction

- \(k_{ij}\) :

-

Thermal conductivity tensor

- \(T\) :

-

Temperature

- \(t\) :

-

Time

- \(Q_{\text{total}}\) :

-

Total heat flow into the mass \(M\) per unit time

- \(C_{p}\) :

-

Specific heat

- \(M\) :

-

Mass

- \(A\) :

-

Area of the triangular element

- \(n_{i}\) :

-

Outward normal unit vector

- \(\bar{T}^{m}\) :

-

Average temperature of edge \(m\)

- \(\Delta x_{j}^{m}\) :

-

Coordinate difference between the two nodes of edge \(m\)

- \(\varepsilon_{ij}\) :

-

Two-dimensional permutation tensor

- q x :

-

Heat flow rate along the x direction

- q y :

-

Heat flow rate along the y direction

- \(n_{i}^{(n)}\) :

-

Outward normal unit vector

- \(L^{(n)}\) :

-

Length of the edge opposite to node \(n\)

- \(Q_{\Delta 123 \to 1}\) :

-

Heat flow flowing into node 1 from triangular element Δ123

- \(T_{i}\) :

-

Temperature at node i

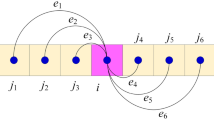

- \(h_{j}\) :

-

Heat exchange coefficients of the joint element

- \(Q_{\Delta 456 \to 1}\) :

-

Heat flow flowing into node 1 from triangular element Δ456

- \(Q_{\Delta 789 \to 1}\) :

-

Heat flow flowing into node 1 from triangular element Δ789

- \(T_{1}^{t + \Delta t}\) :

-

Temperature of node 1 at \(t + \Delta t\)

- \(T_{1}^{t}\) :

-

Temperature of node 1 at \(t\)

- \(k\) :

-

Thermal conductivity coefficient of triangular element

- \(L_{\text{e}}\) :

-

Element size

- \(r_{T}\) :

-

Reduction coefficient

- \(\Delta \sigma_{ij}\) :

-

Stress increment

- \(K\) :

-

Bulk modulus

- \(G\) :

-

Shear modulus

- \(\alpha\) :

-

Thermal expansion coefficient

- \(K^{*}\) :

-

Plane strain problem \(K^{*} = K\), plane stress problem \(K^{*} = 6KG/(3K + 4G)\)

- \(n_{j}\) :

-

Outward normal unit vector of the triangular element edges

- \(T_{1}\) :

-

Temperature at the left boundary

- \(T_{2}\) :

-

Temperature at the right boundary

- \(\kappa\) :

-

Thermal diffusion coefficient (\(\kappa { = }k/\rho C_{p}\) when \(k_{x} = k_{y}\))

- \(W\) :

-

Width

- \(L\) :

-

Length

- \(x\) :

-

The distance from the left boundary

- \(\rho\) :

-

The density

- \(T_{0}\) :

-

The initial temperature

- \(E\) :

-

Elastic modulus

- \(v\) :

-

Poisson’s ratio

- \(f_t\) :

-

Tensile strength

- \(h_f\) :

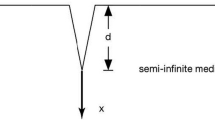

-

Heat exchange coefficient between the water and solid

- α :

-

Thermal expansion coefficient

References

André D, Levraut B, Tessier-Doyen N, Huger M (2017) A discrete element thermo-mechanical modelling of diffuse damage induced by thermal expansion mismatch of two-phase materials. Comput Methods Appl Mech Eng 318:898–916. https://doi.org/10.1016/j.cma.2017.01.029

Bouhala L, Makradi A, Belouettar S (2012) Thermal and thermo-mechanical influence on crack propagation using an extended mesh free method. Eng Fract Mech 88:35–48. https://doi.org/10.1016/j.engfracmech.2012.04.001

Crank J (1975) The mathematics of diffusion, 2nd edn. Oxford University Press, Oxford

Elmo D, Stead D, Eberhardt E, Vyazmensky A (2013) Applications of finite/discrete element modeling to rock engineering problems. Int J Geomech 13(5):565–580. https://doi.org/10.1061/(asce)gm.1943-5622.0000238

Feng YT, Han K, Owen DRJ (2009) Discrete thermal element modelling of heat conduction in particle systems: pipe-network model and transient analysis. Powder Technol 193(3):248–256. https://doi.org/10.1016/j.powtec.2009.03.001

Fu YF, Wong YL, Tang CA, Poon CS (2004) Thermal induced stress and associated cracking in cement-based composite at elevated temperatures—Part II: thermal cracking around multiple inclusions. Cement Concr Compos 26(2):113–126. https://doi.org/10.1016/s0958-9465(03)00087-8

Grasselli G, Lisjak A, Mahabadi OK, Tatone BSA (2014) Influence of pre-existing discontinuities and bedding planes on hydraulic fracturing initiation. Eur J Environ Civ Eng 19(5):580–597. https://doi.org/10.1080/19648189.2014.906367

Guo L, Latham J-P, Xiang J (2017) A numerical study of fracture spacing and through-going fracture formation in layered rocks. Int J Solids Struct 110–111(N):44–57. https://doi.org/10.1016/j.ijsolstr.2017.02.004

Hudson J (1999) Lesson learned from 20 years of UK rock mechanics research for radioactive waste disposal. Int Soc Rock Mech News J 6(1):27–41

Itasca Consulting Group Inc. (2005) Code UDEC. User’s Guide, Minnesota, USA

Jiang CP, Wu XF, Li J, Song F, Shao YF, Xu XH, Yan P (2012) A study of the mechanism of formation and numerical simulations of crack patterns in ceramics subjected to thermal shock. Acta Mater 60(11):4540–4550. https://doi.org/10.1016/j.actamat.2012.05.020

Jiao Y-Y, Zhang X-L, Zhang H-Q, Li H-B, Yang S-Q, Li J-C (2015) A coupled thermo-mechanical discontinuum model for simulating rock cracking induced by temperature stresses. Comput Geotech 67:142–149. https://doi.org/10.1016/j.compgeo.2015.03.009

Lei Z, Rougier E, Knight EE, Munjiza A (2015) FDEM simulation on fracture coalescence in brittle materials. Paper presented at the 49th US Rock Mechanics/Geomechanics Symposium

Lei Q, Latham J-P, Xiang J (2016) Implementation of an empirical joint constitutive model into finite-discrete element analysis of the geomechanical behaviour of fractured rocks. Rock Mech Rock Eng 49(12):4799–4816. https://doi.org/10.1007/s00603-016-1064-3

Li J, Salah WB (2014) Numerical simulations on cracking process in ceramic specimens under thermal shock by using a non-local fracture model. Procedia Mater Sci 3:1492–1498. https://doi.org/10.1016/j.mspro.2014.06.241

Li J, Song F, Jiang C (2015) A non-local approach to crack process modeling in ceramic materials subjected to thermal shock. Eng Fract Mech 133:85–98. https://doi.org/10.1016/j.engfracmech.2014.11.007

Lisjak A, Liu Q, Zhao Q, Mahabadi OK, Grasselli G (2013) Numerical simulation of acoustic emission in brittle rocks by two-dimensional finite-discrete element analysis. Geophys J Int 195(1):423–443. https://doi.org/10.1093/gji/ggt221

Lisjak A, Figi D, Grasselli G (2014) Fracture development around deep underground excavations: insights from FDEM modelling. J Rock Mech Geotech Eng 6(6):493–505. https://doi.org/10.1016/j.jrmge.2014.09.003

Lisjak A, Kaifosh P, He L, Tatone BSA, Mahabadi OK, Grasselli G (2017) A 2D, fully-coupled, hydro-mechanical, FDEM formulation for modelling fracturing processes in discontinuous, porous rock masses. Comput Geotech 81:1–18. https://doi.org/10.1016/j.compgeo.2016.07.009

Liu Y, Wu X, Guo Q, Jiang C, Song F, Li J (2015) Experiments and numerical simulations of thermal shock crack patterns in thin circular ceramic specimens. Ceram Int 41(1):1107–1114. https://doi.org/10.1016/j.ceramint.2014.09.036

Mahabadi O, Kaifosh P, Marschall P, Vietor T (2014) Three-dimensional FDEM numerical simulation of failure processes observed in Opalinus Clay laboratory samples. J Rock Mech Geotech Eng 6(6):591–606. https://doi.org/10.1016/j.jrmge.2014.10.005

Munjiza A (2004) The combined finite-discrete element method. Wiley, London

Munjiza A, Knight EE, Rougier E (2011) Computational mechanics of discontinua. Wiley, London

Munjiza A, Knight EE, Rougier E (2015) Large strain finite element method: a practical course. Wiley, London

Munjiza A, Owen DRJ, Bicanic N (1995) A combined finite-discrete element method in transient dynamics of fracturing solids. Eng Comput 12(2):145–174. https://doi.org/10.1108/02644409510799532

Munjiza A, Latham JP, Andrews KRF (1999) Challenges of a coupled combined finite-discrete element approach to explosive induced rock fragmentation. Fragblast 3(3):237–250. https://doi.org/10.1080/13855149909408048

Munjiza A, Andrews K, White J (1999) Combined single and smeared crack model in combined finite-discrete element analysis. Int J Numer Methods Eng 44(1):41–57

Raude S, Laigle F, Giot R, Fernandes R (2015) A unified thermoplastic/viscoplastic constitutive model for geomaterials. Acta Geotech 11(4):849–869. https://doi.org/10.1007/s11440-015-0396-6

Rougier E, Knight EE, Broome ST, Sussman AJ, Munjiza A (2014) Validation of a three-dimensional finite-discrete element method using experimental results of the Split Hopkinson Pressure Bar test. Int J Rock Mech Min Sci 70(N):101–108. https://doi.org/10.1016/j.ijrmms.2014.03.011

Tang SB, Zhang H, Tang CA, Liu HY (2016) Numerical model for the cracking behavior of heterogeneous brittle solids subjected to thermal shock. Int J Solids Struct 80:520–531. https://doi.org/10.1016/j.ijsolstr.2015.10.012

Wang Y, Zhou X, Kou M (2018) A coupled thermo-mechanical bond-based peridynamics for simulating thermal cracking in rocks. Int J Fract. https://doi.org/10.1007/s10704-018-0273-z

Wanne TS, Young RP (2008) Bonded-particle modeling of thermally fractured granite. Int J Rock Mech Min Sci 45(5):789–799. https://doi.org/10.1016/j.ijrmms.2007.09.004

Wu Z, Sun H, Wong LNY (2019) A cohesive element-based numerical manifold method for hydraulic fracturing modelling with voronoi grains. Rock Mech Rock Eng. https://doi.org/10.1007/s00603-018-1717-5

Xia M, Zhao C, Hobbs BE (2014) Particle simulation of thermally-induced rock damage with consideration of temperature-dependent elastic modulus and strength. Comput Geotech 55:461–473. https://doi.org/10.1016/j.compgeo.2013.09.004

Yan C, Jiao Y-Y (2018) A 2D fully coupled hydro-mechanical finite-discrete element model with real pore seepage for simulating the deformation and fracture of porous medium driven by fluid. Comput Struct 196(N):311–326. https://doi.org/10.1016/j.compstruc.2017.10.005

Yan C, Jiao Y-Y (2019) FDEM‐TH3D: a three‐dimensional coupled hydrothermal model for fractured rock. Int J Numer Anal Methods Geomech 43(1):415–440. https://doi.org/10.1002/nag.2869

Yan C, Zheng H (2016) A two-dimensional coupled hydro-mechanical finite-discrete model considering porous media flow for simulating hydraulic fracturing. Int J Rock Mech Min Sci 88(N):115–128. https://doi.org/10.1016/j.ijrmms.2016.07.019

Yan CZ, Zheng H (2017) A new potential function for the calculation of contact forces in the combined finite-discrete element method. Int J Numer Anal Methods Geomech 41(2):265–283. https://doi.org/10.1002/nag.2559

Yan C, Zheng H (2017) FDEM-flow3D: a 3D hydro-mechanical coupled model considering the pore seepage of rock matrix for simulating three-dimensional hydraulic fracturing. Comput Geotech 81(N):212–228. https://doi.org/10.1016/j.compgeo.2016.08.014

Yan C, Zheng H (2017) Three-dimensional hydromechanical model of hydraulic fracturing with arbitrarily discrete fracture networks using finite-discrete element method. Int J Geomech 17(6):04016133

Yan C, Zheng H (2017) A coupled thermo-mechanical model based on the combined finite-discrete element method for simulating thermal cracking of rock. Int J Rock Mech Min Sci 91(N):170–178. https://doi.org/10.1016/j.ijrmms.2016.11.023

Yan C, Zheng H, Sun G, Ge X (2016) Combined finite-discrete element method for simulation of hydraulic fracturing. Rock Mech Rock Eng 49(4):1389–1410. https://doi.org/10.1007/s00603-015-0816-9

Yan C, Jiao Y-Y, Yang S (2019) A 2D coupled hydro-thermal model for the combined finite-discrete element method. Acta Geotech 14(2):403-416. https://doi.org/10.1007/s11440-018-0653-6

Yan C, Jiao Y-Y, Zheng H (2018) A fully coupled three-dimensional hydro-mechanical finite discrete element approach with real porous seepage for simulating 3D hydraulic fracturing. Comput Geotech 96(N):73–89. https://doi.org/10.1016/j.compgeo.2017.10.008

Yang Y, Tang X, Zheng H, Liu Q, He L (2016) Three-dimensional fracture propagation with numerical manifold method. Eng Anal Bound Elem 72:65–77. https://doi.org/10.1016/j.enganabound.2016.08.008

Yu QL, Ranjith PG, Liu HY, Yang TH, Tang SB, Tang CA, Yang SQ (2014) A mesostructure-based damage model for thermal cracking analysis and application in granite at elevated temperatures. Rock Mech Rock Eng 48(6):2263–2282. https://doi.org/10.1007/s00603-014-0679-5

Zhang HH, Ma GW, Ren F (2014) Implementation of the numerical manifold method for thermo-mechanical fracture of planar solids. Eng Anal Bound Elem 44:45–54. https://doi.org/10.1016/j.enganabound.2014.04.002

Zhao Q, Lisjak A, Mahabadi O, Liu Q, Grasselli G (2014) Numerical simulation of hydraulic fracturing and associated microseismicity using finite-discrete element method. J Rock Mech Geotech Eng 6(6):574–581. https://doi.org/10.1016/j.jrmge.2014.10.003

Zhu C, Arson C (2013) A thermo-mechanical damage model for rock stiffness during anisotropic crack opening and closure. Acta Geotech 9(5):847–867. https://doi.org/10.1007/s11440-013-0281-0

Acknowledgements

This work was supported by the National Natural Science Foundation of China under Grant Nos. 11872340, 11602006; the Beijing Natural Science Foundation under Grant No. 1174012; the Fundamental Research Funds for the Central Universities, China University of Geosciences (Wuhan) (CUG170657); the Chaoyang District Postdoctoral Science Foundation project funded under Grant No. 2016ZZ-01-08; and the National Natural Science Foundation of China under Grant No. 41731284.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Yan, C., Jiao, YY. A 2D discrete heat transfer model considering the thermal resistance effect of fractures for simulating the thermal cracking of brittle materials. Acta Geotech. 15, 1303–1319 (2020). https://doi.org/10.1007/s11440-019-00821-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11440-019-00821-x