Abstract

Iridium–nickel (Ir–Ni) film is of great interest for catalytic and corrosive environment applications. Ir–Ni thin films as an electrocatalyst for hydrogen evolution reaction (HER) were galvanostatically electrodeposited on copper (Cu) foam from an electrolyte containing 13.5 mM sodium hexabromoiridate(III) and 40.5 mM Ni sulphate hexahydrate, simultaneously compared with electrodeposited Ir and Ni thin films. The top surface morphology of the film was characterized by scanning electron microscopy. The chemical composition of the film was determined by energy-dispersive spectroscopy and X-ray photoelectron spectroscopy. The electrocatalytic performance was performed by linear sweep voltammogram and cyclic voltammetry. The results showed that Ir–Ni thin film adhered to Cu foam and the surface appeared much rougher than the surface of Ni film. The chemical composition of Ir in the deposit was 80 ± 1.2 at.%. The film was composed of nanograins. The top surface of as-deposited film was mainly composed of metallic state. However, the top surface of the film consisted of oxides states, such as Ni oxides or Ni(OH)2, and Ir oxides after electrochemical measurements. As-deposited Ir–Ni thin film with large real active area exhibited high efficient electrocatalytic activity for HER, and achieved a current density of 10 mA cm2 at an overpotential of 60 mV and a Tafel slope of 40 mV dec−1, which is superior to pure Ir and Ni thin films. The remarkable increase in electrocatalytic activity for Ir–Ni film was ascribed to both increased surface area of active centers due to relatively rough and electrocatalytic synergism of Ir and Ni for the HER.

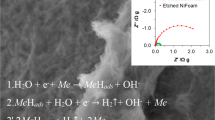

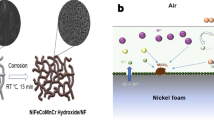

Graphic Abstract

Ir–Ni thin film electrodeposited on a foam copper electrode was used as an electrocatalyst for HER. The surface of as-deposited film was composed of metallic state. As-deposited Ir–Ni thin film with large real active area exhibited high efficient electrocatalytic activity for HER, and achieved a current density of 10 mA cm2 at an overpotential of 60 mV and a Tafel slope of 40 mV dec−1, which is superior to pure iridium and Ni thin films. As-deposited film possessed a good stability by accelerated degradation studies.

Similar content being viewed by others

References

Armaroli N, Balzani V (2011) ChemSusChem 4:21

Merki D, Stéphane F, Vrubel H et al (2011) J Chem Sci 2:1262

Strmcnik D, Lopes PP, Genorio B et al (2016) Nano Energy 29:29

Wu WP, Chen ZF, Wang LB (2015) Prot Met Phys Chem Surf 51:607

Wu WP, Jiang JJ, Chen ZF (2016) Acta Astronaut 123:1

Wu WP, Chen ZF (2016) Surf Interface Anal 48:353

Singh SK, Xu Q (2010) Chem Commun 46:6545

Kuttiyiel KA, Sasaki K, Chen WF et al (2014) J Mater Chem A 2:591

Moghaddam RB, Wang C, Sorge JB et al (2015) Electrochem Commun 60:109

Özer E, Sinev I, Mingers AM et al (2018) Surfaces 1:165

He L, Huang Y, Liu XY et al (2014) Appl Catal B 147:779

Jović BM, Lačnjevac UČ, Jović VD et al (2015) Int J Hydrog Energy 40:10480

Wu WP, Chen ZF (2017) Johns Matthey Technol Rev 61:16

Wu WP, Chen ZF (2017) Johns Matthey Technol Rev 61:93

Wu WP, Jiang JJ, Chen ZF (2017) J Wuhan Univ Technol Mater Sci Ed 32:190

Ohsaka T, Matsubara Y, Hirano K et al (2007) Trans Inst Met Finish 85:265

Safizadeh F, Ghali E, Houlachi G (2015) Int J Hydrog Energy 40:256

Eftekhari A (2017) Int J Hydrog Energy 42:11053

Ahn SH, Tan H, Haensch M et al (2015) Energy Environ Sci 8:3557

Sawy ENE, Birss VI (2009) J Mater Chem 19:8244

Wessling B, Mokwa W, Schnakenberg U (2008) J Electrochem Soc 155:61

Papaderakis A, Pliatsikas N, Patsalas P et al (2018) J Electroanal Chem 808:21

Duca M, Guerrini E, Colombo A et al (2013) Electrocatalysis 4:338

Chen ZF, Zhao HB, Zhang JJ et al (2009) Sci China Mater 60:119

Sasaki K, Kuttiyiel KA, Barrio L et al (2011) J Phys Chem C 115:9894

Wu WP, Jiang JJ, Jiang P et al (2018) Appl Surf Sci 434:307

Wu WP, Wang ZZ, Jiang P et al (2017) J Electrochem Soc 164:D985

Näther J, Köster F, Freudenberger R et al (2017) IOP Conf Ser Mater Sci Eng 181:012041

Wu WP (2016) Appl Phys A 122:1028

Wu WP, Eliaz N, Gileadi E (2016) Thin Solid Films 616:828

Wu WP (2016) Electrochemistry 84:699

Wu WP, Eliaz N, Gileadi E (2014) J Electrochem Soc 162:D20

Wu WP, Liu JW, Miao NM et al (2019) J Mater Sci Mater Electron 30:7717

Wu WP, Liu JW, Zhang Y et al (2019) J Appl Electrochem 49:1043

Jin GP, Peng X, Ding YF et al (2009) J Solid State Electrochem 13:967

Chen R-S, Korotcov A, Huang Y-S et al (2006) Nanotechnology 17:R67

Wu WP, Liu JW, Zhang Y et al (2019) Surf Eng 35:954

Yao KL, Zhai MH, Ni YH (2019) Electrochim Acta 301:87

Yao YW, Jiao LM, Yu NC et al (2016) Russ J Electrochem 52:348

Shervedani RK, Torabi M, Yaghoobi F (2017) Electrochim Acta 244:230

Bockris JO, Potter EC (1952) J Electrochem Soc 99:169

Chen WF, Wang CH, Sasaki K et al (2013) Energy Environ Sci 6:943

Deng J, Ren P, Deng D et al (2015) Angew Chem Int Ed 127:2128

Li DJ, Maiti UN, Lim J et al (2014) Nano Lett 14:1228

Gao MY, Yang C, Zhang QB et al (2016) Electrochim Acta 215:609

Fang M, Gao W, Dong GF et al (2016) Nano Energy 27:247

Elisa NF, Chong ZW, Omanovic S (2005) J Mol Catal A 226:179

Ezaki H, Morinaga M, Watanabe S (1993) Electrochim Acta 38:557

Fan CL, Piron DL, Abderrahman S et al (1994) J Electrochem Soc 141:382

Highfield JG, Claude E, Oguro K (1999) Electrochim Acta 44:2805

Hahn F, Beden B, Croissant MJ et al (1986) Electrochim Acta 31:335

Dong SJ, Xie YW, Cheng GG (1992) Electrochim Acta 37:17

Mozota J, Conway BE (1983) Electrochim Acta 28:1

Kötz R, Neff H, Stucki S (1984) J Electrochem Soc 131:72

Eliaz N, Gileadi E (2018) Physical electrochemistry—fundamentals, techniques, and applications, 2nd edn. Wiley-VCH, Weinheim, p 327

Acknowledgements

The authors wish to thank referee’s constructive suggestions and comments and want to thank Mr. Yajun Xue from the Nanjing Institute of Technology for his helpful contribution in EDS elemental mapping and XPS characterizations of the samples. This research was partially supported by National Natural Science Foundation of China (Grant Nos. 61604021, 51875053), Changzhou Sci and Tech Program (Grant No. CJ20190041) and the Natural Science Foundation of Jiangsu Province (Grant No. BK20150260). Dr. Wangping Wu (WPW) thanks the China Scholarship Council (CSC) an “Agreement for Study Abroad for CSC Sponsored Chinese Citizens” awarded a scholarship under the State Scholarship Fund to pursue study in Germany as a Visiting Scholar. PhD Candidate Mr. Näther Johannes (NJ) also thanks an Academic Exchange Project supported by In Pro Technische Universität Chemnitz (TUC).

Author information

Authors and Affiliations

Contributions

WPW designed the study and supervised an MSc Student, JWL, who performed most of the experiments, and contribute to the first preparation of this article. TSH, YZ, and LL supervised the preparation and pretreatment process of Cu foam and discussed it. NJ guided the experiment of Ir layer and supported chemical-sodium hexabromoiridate(III), JWL prepared film electrodes, LSV and CV testing and stability of the electrode. LZ conducted the SEM/EDS experiments and assisted in their data analysis. WPW, YZ, and LL discussed the results. JWL wrote the manuscript. WPW has carefully revised the manuscript according to the referee’s comments. All authors approved the submission of the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

We declare that we do not have any commercial or associative interest that represents a conflict of interest in connection with the work submitted.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wu, W., Liu, J., Johannes, N. et al. Galvanostatic Electrodeposition of Thin-Film Ir–Ni Electrocatalyst on Copper Foam for HER Performance in Alkaline Electrolyte. Catal Lett 150, 1325–1336 (2020). https://doi.org/10.1007/s10562-019-03038-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s10562-019-03038-5